Facility and method jointly performing the compression of acidic gases from the hydroconversion or hydrotreating unit and of the tail gas from the catalytic cracking unit

A hydroconversion and catalytic cracking technology, applied in catalytic cracking, effluent separation, hydrotreating processes, etc., can solve the problem of acid gas not being removed, and achieve the effect of low marginal cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

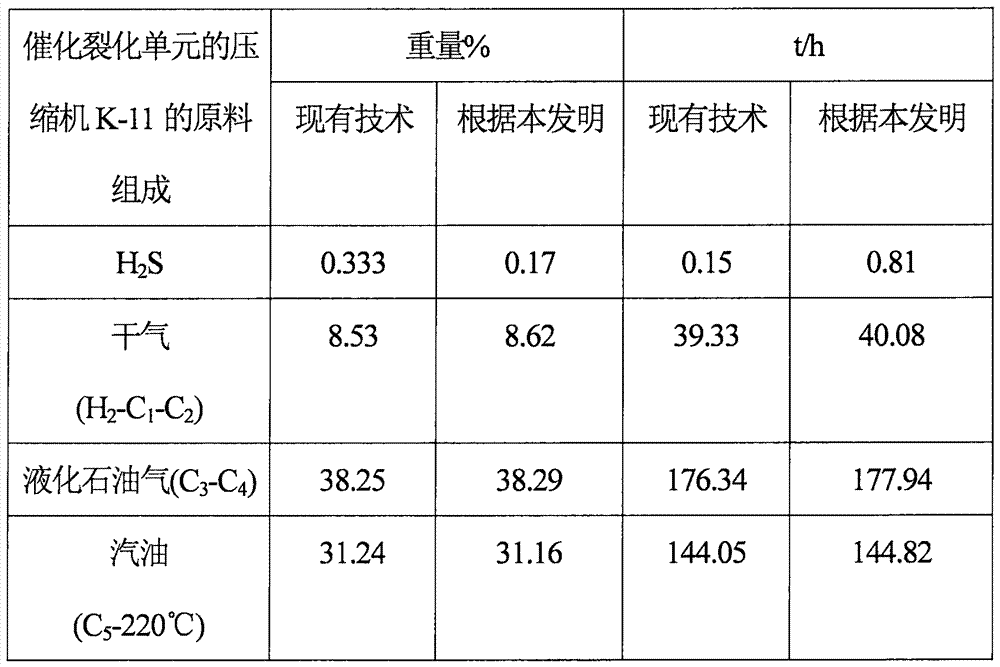

[0093] Table 1 below shows a system according to the prior art, i.e. with a compressor for the top gas of the main fractionation column C-1, and according to the invention, i.e. with only compression of the cracked gas for the catalytic cracking unit R-11 The results obtained for machine K-11, both of which also treated the top gas of fractionation column C-1.

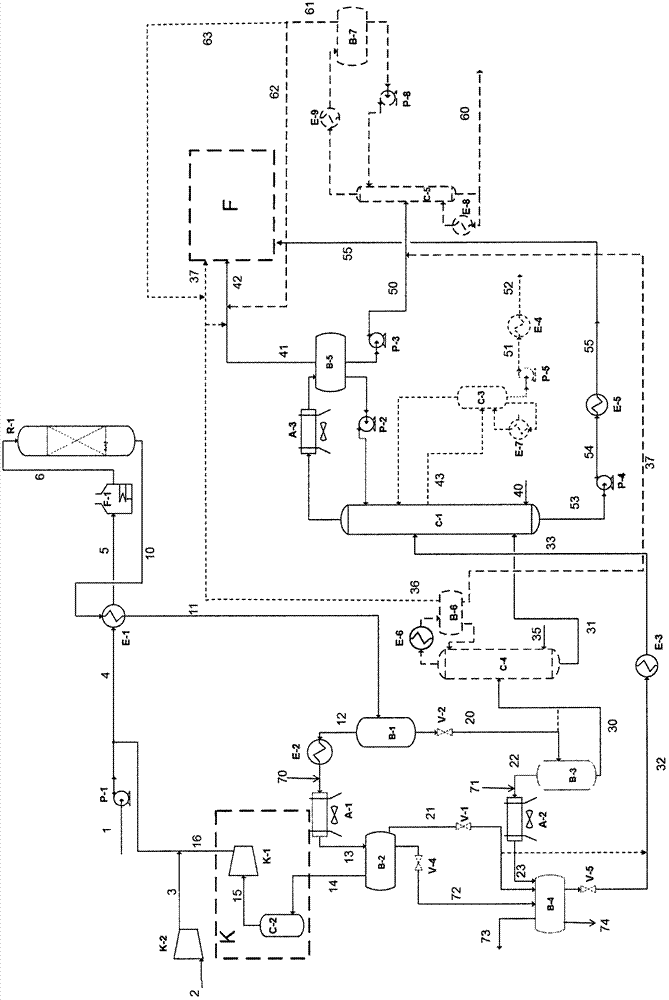

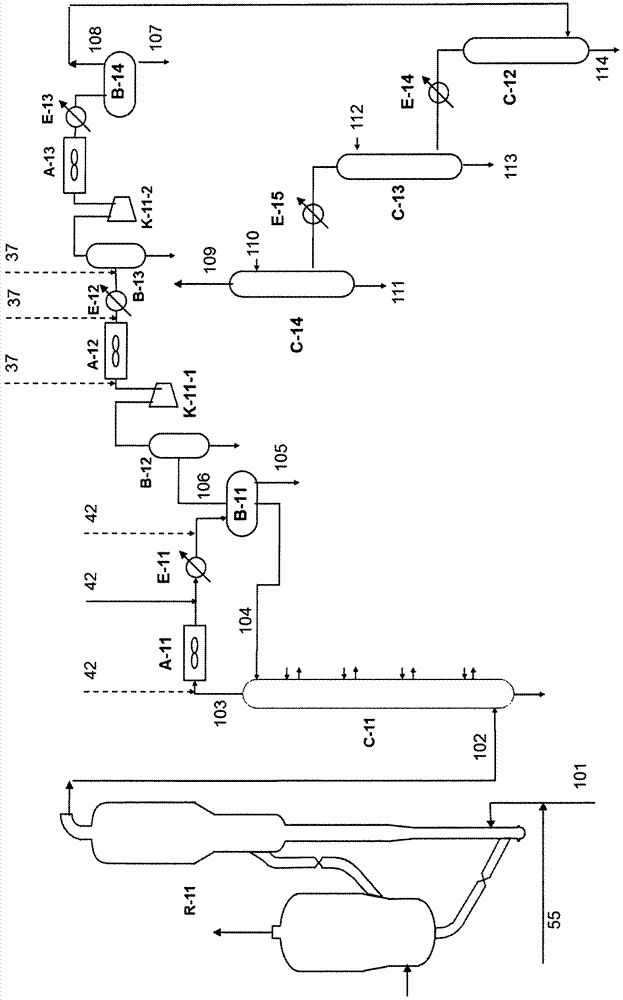

[0094] An embodiment according to the invention corresponds to figure 1 and figure 2 layout without the optional towers C-3, C-4, C-5 and figure 1 Corresponding segments indicated by dotted lines in .

[0095] According to the layout of the invention, the top compressor of the main fractionator C-1 of the hydroconversion or hydrotreatment section R-1 is suppressed due to the integration with the recovery compressor K-11 for the gaseous effluent of the catalytic cracking unit .

[0096] Due to the additional stream 42, the increase in the total flow at the inlet of the compressor K-11 of the catalytic cracking sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com