Taking mechanism of coiled material

A technology of coiled material and transmission mechanism, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems such as the inability to limit the setting position of the slider and the slope chute, the suspension of the transportation process of the coiled material product, and the reduction of work efficiency, etc. The effect of increasing the lifting force area, avoiding excessive extrusion damage, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

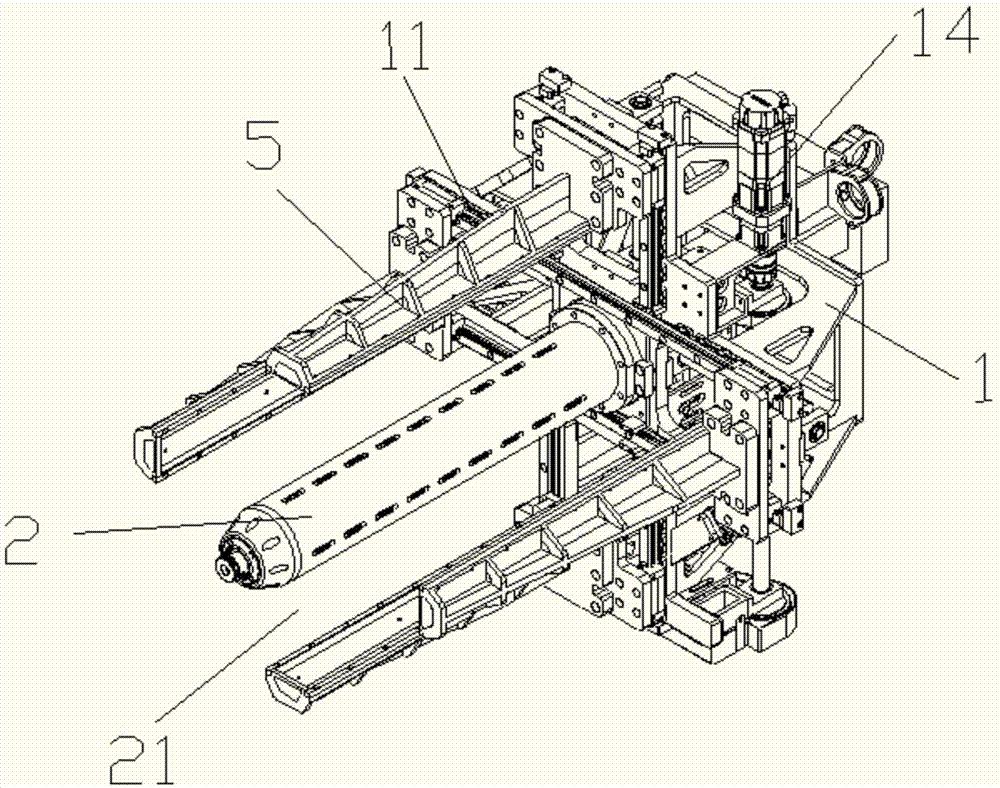

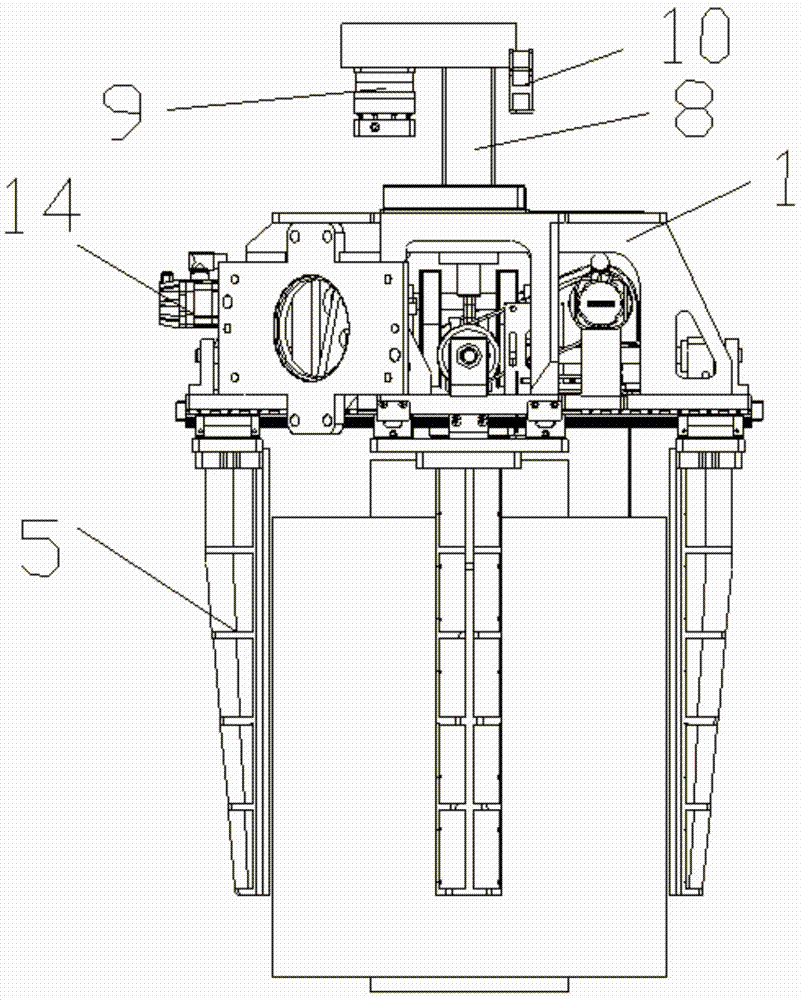

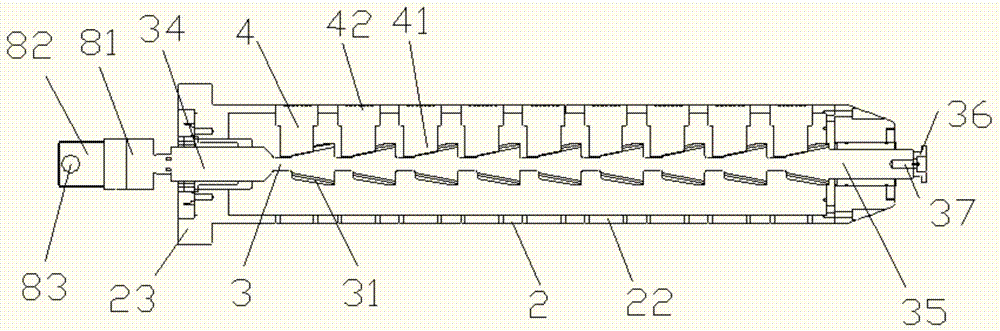

[0032] During the use of the present invention, the outward movement of the pressing block 4 in the sleeve 2 fully contacts the channel of the coiled material product, thereby generating greater friction. Such as figure 1 As shown, four splints 5 are evenly distributed on the outside of the coiled material product, and the setting direction of the splints 5 is parallel to the axis of the sleeve 2 at the same time. When taking the coiled material product, the clamping plate 5 moves horizontally towards the sleeve 2, and at this moment, a coiled material product receiving groove 21 is formed between the clamping plate 5 and the reel 2. Four splints 5 are in full contact with the outer surface of the coiled material product, so that greater frictional force is produced therebetween. Since the contact area between the splint 5 and the coiled mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com