Caked cement barrel cleaning device for building

A cleaning device, a technology for construction, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of low work efficiency, soiling clothes, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

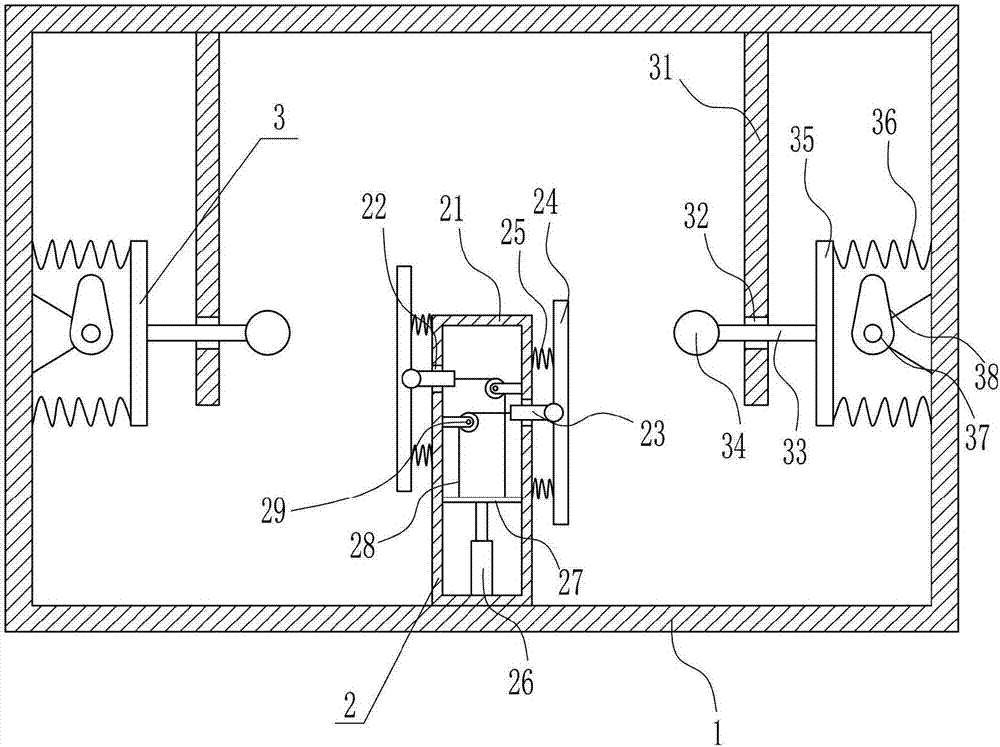

[0022] A kind of agglomerated cement barrel cleaning device for construction, such as Figure 1-2 As shown, it includes a first box body 1, a fixing device 2 and a knocking device 3. A fixing device 2 is provided in the middle of the bottom of the first box body 1, and a knocking device 3 is provided on the left and right sides of the first box body 1. .

Embodiment 2

[0024] A kind of agglomerated cement barrel cleaning device for construction, such as Figure 1-2 As shown, it includes a first box body 1, a fixing device 2 and a knocking device 3. A fixing device 2 is provided in the middle of the bottom of the first box body 1, and a knocking device 3 is provided on the left and right sides of the first box body 1. .

[0025]The fixing device 2 includes a second box body 21, a guide rod 23, a first movable plate 24, a first spring 25, a cylinder 26, a second movable plate 27, a first backguy 28 and a pulley 29, and the inner bottom of the first box body 1 A second box body 21 is installed in the middle by means of bolt connection, and first through holes 22 are formed on the upper left side and the upper right side of the second box body 21, and a guide rod 23 is arranged in the first through hole 22, and the guide rod 23 is arranged on the left side. The left end of the rod 23 and the right end of the right side guide rod 23 are all conn...

Embodiment 3

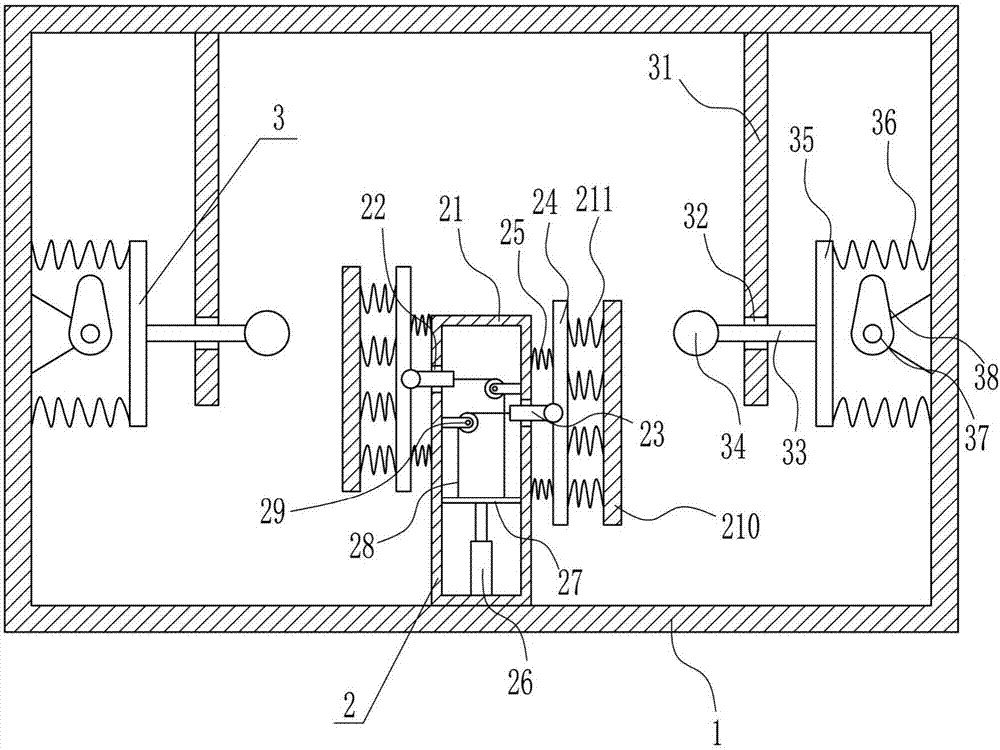

[0027] A kind of agglomerated cement barrel cleaning device for construction, such as Figure 1-2 As shown, it includes a first box body 1, a fixing device 2 and a knocking device 3. A fixing device 2 is provided in the middle of the bottom of the first box body 1, and a knocking device 3 is provided on the left and right sides of the first box body 1. .

[0028] The fixing device 2 includes a second box body 21, a guide rod 23, a first movable plate 24, a first spring 25, a cylinder 26, a second movable plate 27, a first backguy 28 and a pulley 29, and the inner bottom of the first box body 1 A second box body 21 is installed in the middle by means of bolt connection, and first through holes 22 are formed on the upper left side and the upper right side of the second box body 21, and a guide rod 23 is arranged in the first through hole 22, and the guide rod 23 is arranged on the left side. The left end of the rod 23 and the right end of the right side guide rod 23 are all con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com