Wide-ridge double-line straw deep burying returning machine

A technology of large ridges and double rows and straws is applied to the field of deep-buried straw returning machines in the corn large ridge and double row planting mode, so as to achieve the effects of preventing missed cutting and clogging, fertilizing soil fertility and enhancing soil organic matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

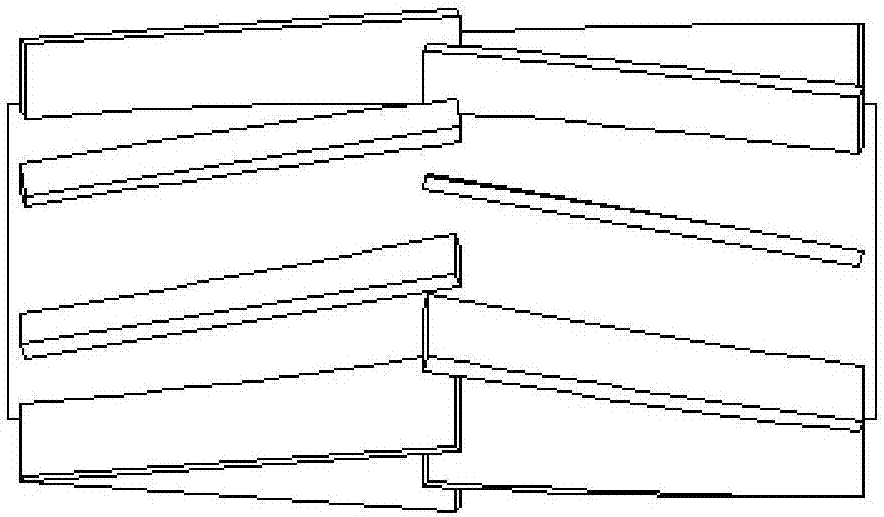

[0038] Example: such as figure 1 As shown, a large ridge double-row straw returning machine of the present invention includes a frame 1, a gearbox 9, a transmission device 8, a straw collecting device 2 arranged sequentially from the working front end to the rear end installed on the frame 1, a medicine Box device 7, burying device 6, soil covering device 5 and suppressing device 4. The straw collection device 2 is composed of two groups of spiral rollers 21 connected symmetrically through a connecting shaft 25, and the connecting shaft 25 is fixed on the frame 1 through a connecting plate 22. Above, each group of spiral rollers 21 is composed of two groups of symmetrically inclined blades, which chop straw and weeds and collect them from both sides to the middle; the rotating shaft cylinder 63 of the buried device 6 is connected to the gearbox 9 The output shaft of the output shaft, the rotating shaft cylinder 63 is connected with the straw collection device 2, the rotary spa...

Embodiment 2

[0051] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the included angle α between the blade of the spiral roller and the horizontal line in this embodiment is 15°; the edge angle of the cutting edge on the blade is 14°. The installation angle β of the rotary spade blade 65 is 81°. The phase angle γ between the soil support plate and the rotary shovel blade 65 is 60°.

Embodiment 3

[0052] Embodiment 3: The difference between this embodiment and Embodiment 1 is that: the included angle α between the blade of the spiral roller and the horizontal line in this embodiment is 18°; the edge angle of the cutting edge on the blade is 20°. The installation angle β of the rotary spade blade 65 is 75°. The phase angle γ between the soil support plate and the rotary spade blade 65 is 50°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com