Dual-floater direct-drive type wave power generation system based on speed-increasing type linear permanent magnet generator

A permanent magnet generator and wave power generation technology, which is applied to ocean energy power generation, engine components, machines/engines, etc., can solve the problems of large volume and mass of generators, difficulties in installation, commissioning and maintenance, and reduced system efficiency, so as to achieve energy Capturing and energy conversion functions, reducing the cost of manufacturing and the complexity of installation and debugging, and the effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

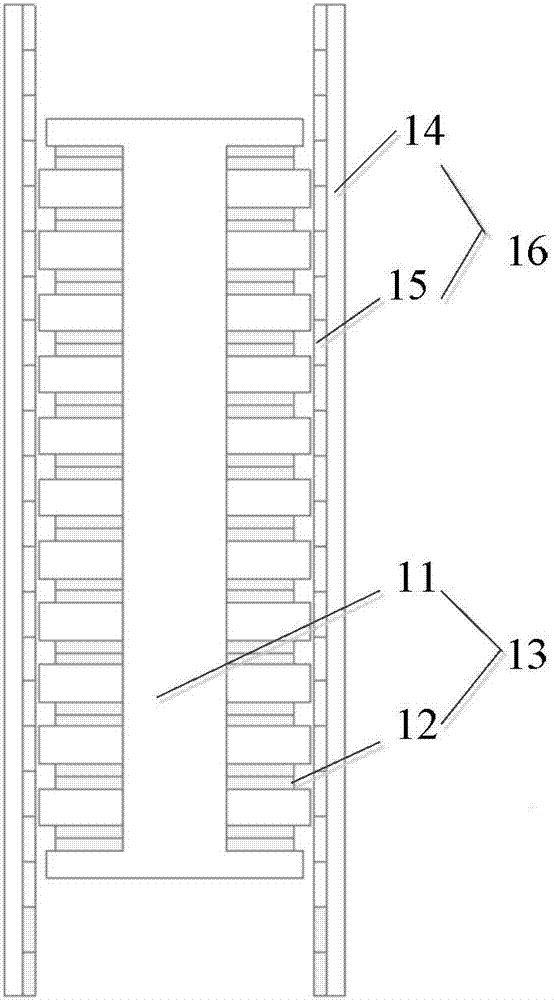

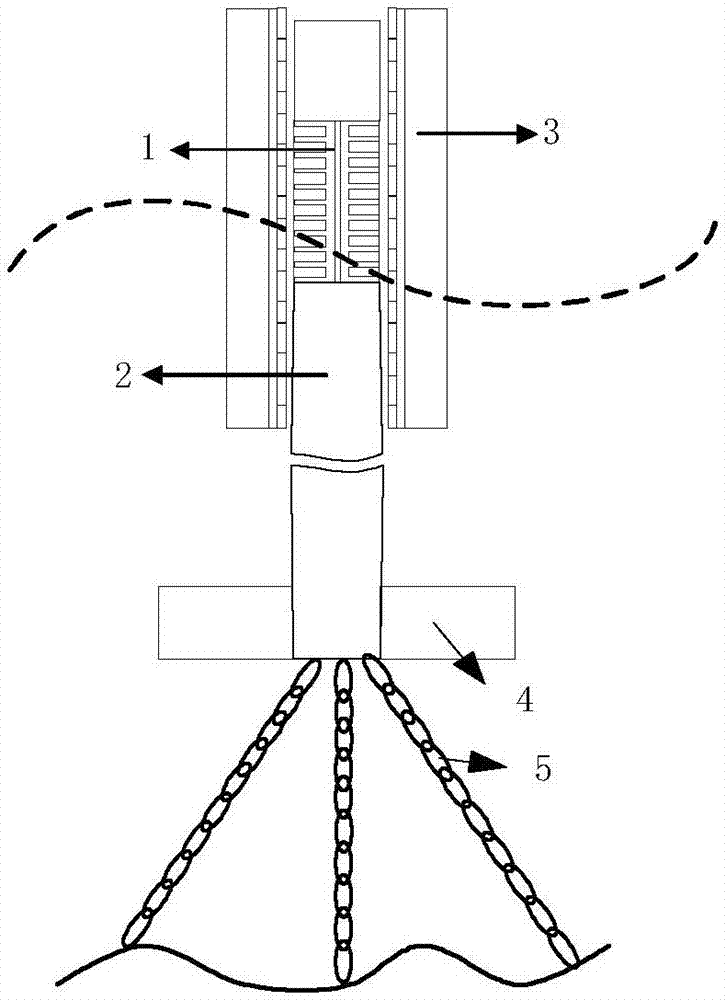

[0039] The direct-drive wave power generation system of the present invention includes a speed-increasing linear permanent magnet generator 1, an inner buoy 2 and an outer buoy 3, a damping disc 4, and an anchor chain 5; the speed-increasing linear permanent magnet generator 1 includes The stator 13 and the mover 16; the generator stator 13 is composed of the stator core 11 and the armature winding 12; the generator mover 16 is composed of the mover core 14 and the mover arranged in a surface-mounted or embedded manner along the inner surface of the mover core 14 Sub permanent magnet 15 forms;

[0040] The stator core 11 and armature winding 12 of the speed-increasing linear permanent magnet generator 1 are installed inside the inner buoy 2; 15 installed inside the outer buoy 3;

[0041] The invention adopts a speed-increasing linear permanent magnet genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com