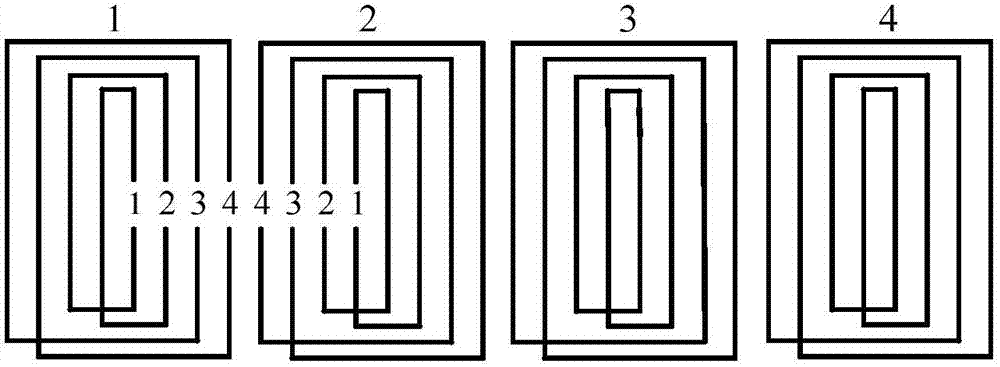

Brushless doubly-fed machine hybrid cage type rotor structure and winding method

A cage-type rotor and doubly-fed motor technology, which is applied in the field of variable-frequency speed-regulating drive and variable-speed constant-frequency power generation, can solve problems such as unreliable welding, inconvenient winding of hybrid cage-type rotors, and poor insulation performance, and reduce processing costs. Difficulty and manufacturing cost, low harmonic content, and the effect of reducing winding copper loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

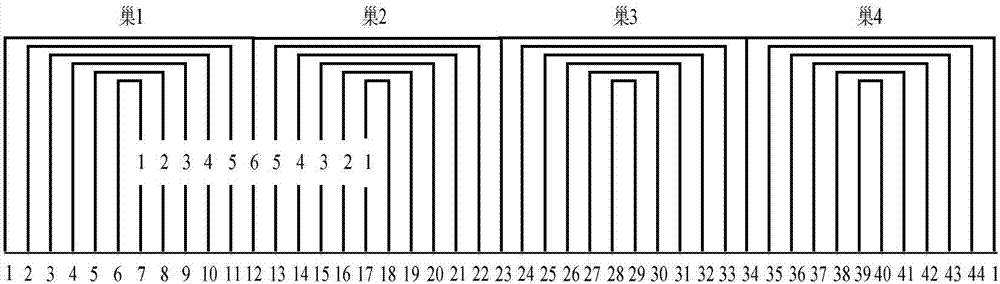

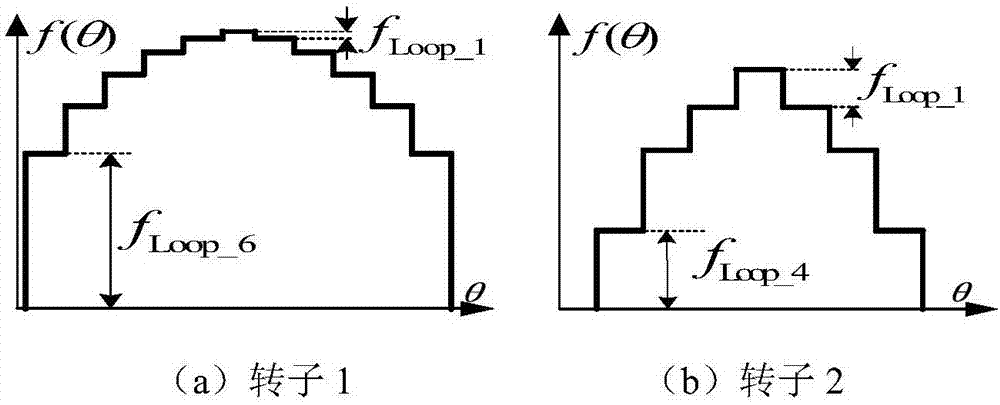

Embodiment Construction

[0039] The current research shows that as the number of short-circuit rings in the rotor nest increases, the modulation effect of the rotor magnetic field increases, and the harmonic leakage reactance and resistance of the rotor decrease. When the number of short-circuit rings exceeds a certain number, the rotor core tends to be saturated and the rotor impedance decreases. The magnitude is also gradually reduced. With the increase of the number of short-circuit rings, the spacing of the short-circuit rings in the rotor nest is not equal, the current distribution of each short-circuit ring is unbalanced, and the magnetomotive force of the cage rotor winding is not sinusoidally distributed, which contains abundant useless harmonic magnetomotive forces. Moreover, due to the uneven distribution of rotor current, the equivalent cross-sectional area of the rotor conductor becomes smaller and the equivalent resistance is larger, which not only reduces the utilization rate of materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com