Sampling measurement system and sampling measurement method

A technology for measuring and measuring data, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as waste of resources, improve manufacturing yield, reduce process risks, and reduce The effect of product scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It can be known from the background technology that the sampling measurement system in the prior art has the problem of adjustment lag. Now combine the sampling method of the sampling measurement system in the prior art to analyze the reasons for the adjustment lag:

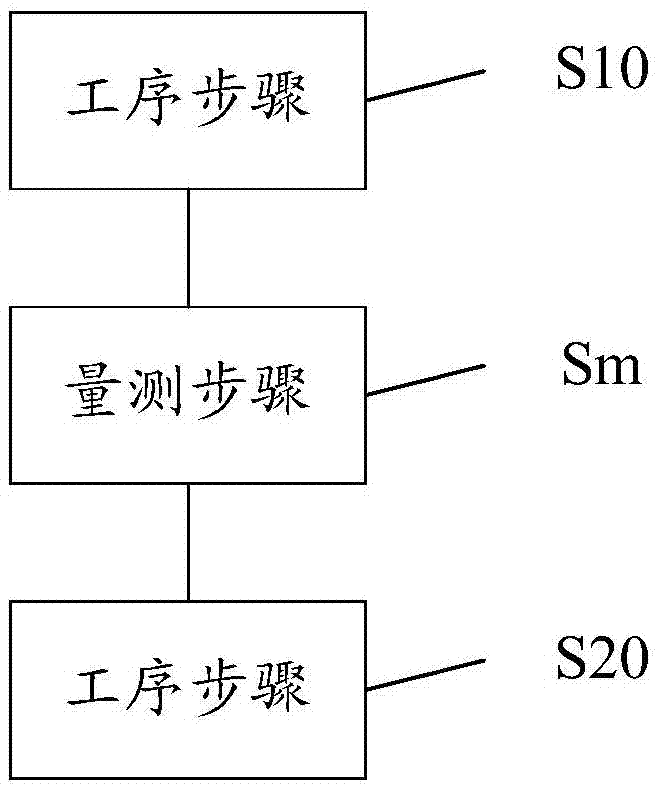

[0017] reference figure 1 , Shows a fragmentary flow chart of the semiconductor device production process in the prior art.

[0018] In the prior art, the wafer sequentially executes each process according to a preset process flow. The process step S10 and the process step S20 are any two adjacent semiconductor process steps that are connected back and forth. After the process step S10 and before the process step S20, perform the measurement step Sm to measure the work in process to determine whether the work in process after the process step S10 is qualified or not, and the measured work in progress enters the subsequent process step S20 for production .

[0019] In the measurement step Sm, the measurement ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com