System for resin transfer redundancy automatic control in treatment process of leaching solution

An automatic control system and process technology, applied in general control systems, control/regulation systems, program control, etc., to solve problems such as semi-automation, low reliability of a single controller, and production interruptions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

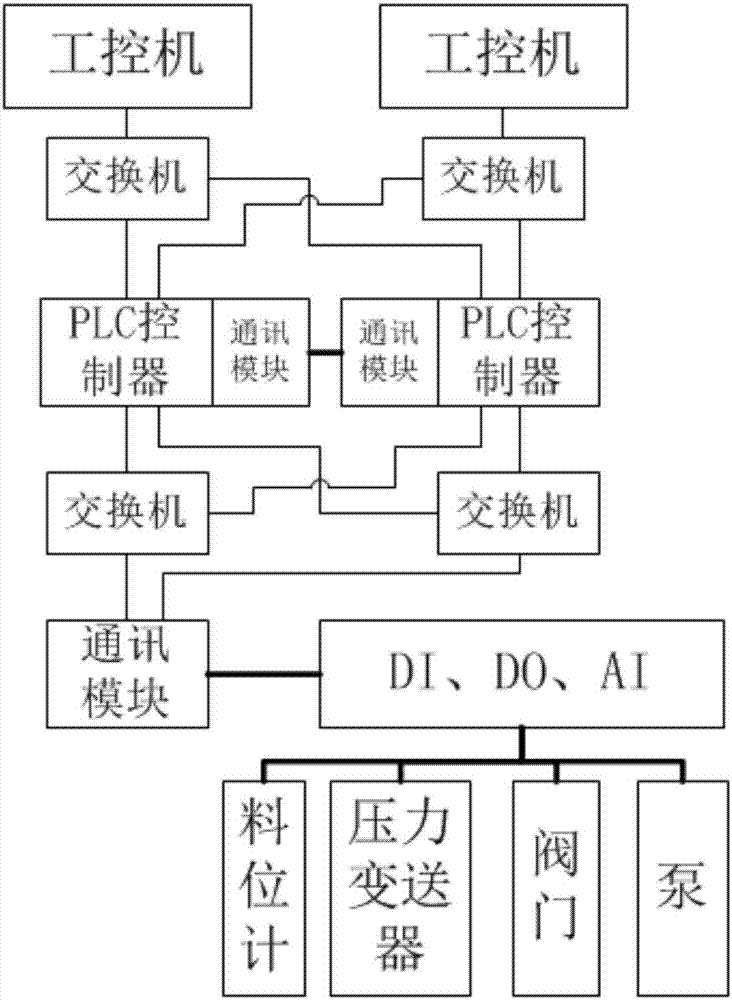

[0014] Such as figure 1 As shown, the resin transfer redundant automatic control system of the leaching solution treatment process of the present invention includes a PLC controller, which is responsible for the execution of the entire system instructions, data storage and transmission, and is used to obtain after logical calculation according to the input digital and analog quantities. Contains the control command of predetermined data, and outputs the control command; the communication module realizes the redundant synchronization function of the PLC system and completes the network transmission of data; the DI input module is used to input the operating status of valves and pumps in the form of digital quantities PLC controller; DO output module, used to send control commands output by the PLC controller to valves and pumps; AI input modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com