A performance adjustment device and construction method for large cantilever concrete flange of main girder

A technology of adjusting device and concrete, which is applied in the direction of bridge construction, building, bridge, etc., to ensure the safety and improve the working condition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

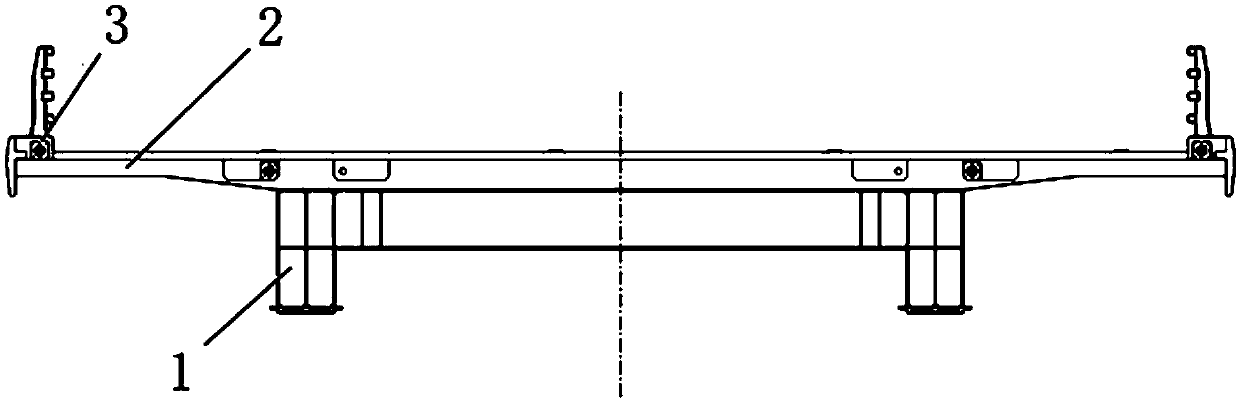

[0028] The 35m-span steel plate composite continuous girder bridge adopts a steel plate composite girder 1 with a full width of 16.25m and double main girders. The 3.9m large cantilever concrete flange 2 is affected by the shear lag of the beam body and the negative transverse bending moment, and there is a problem of cracking under force.

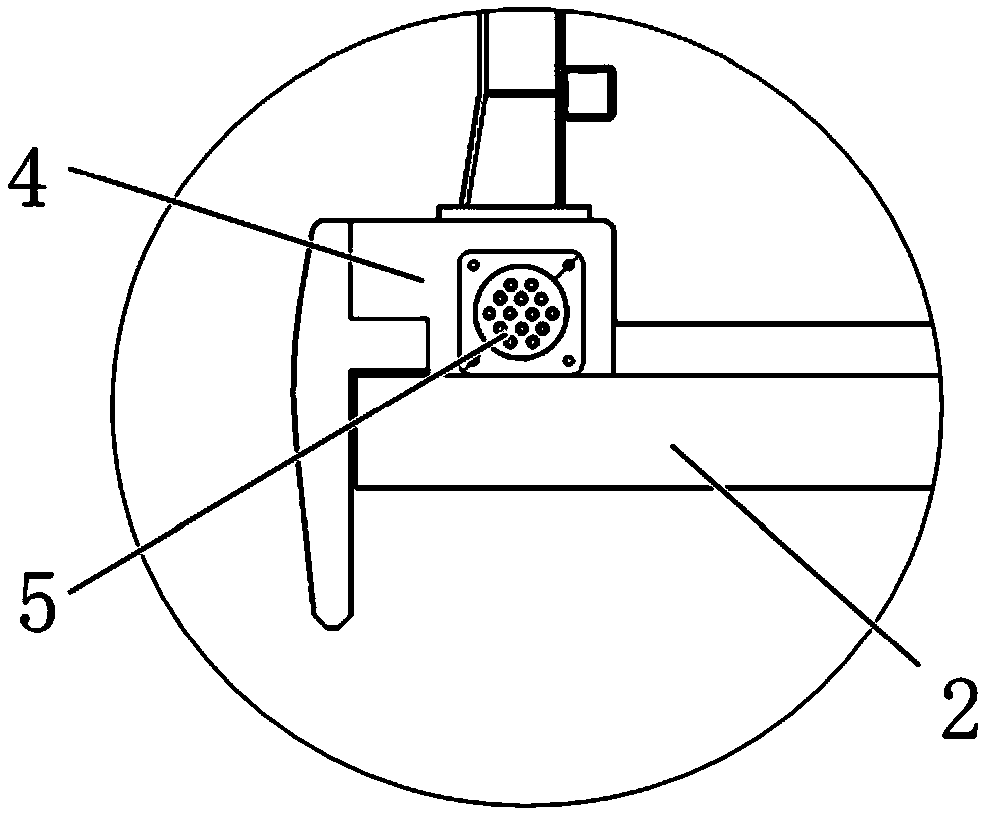

[0029] see figure 1 and figure 2 , it is designed to install a performance adjustment device 3 at the end of the large cantilever concrete flange 2 to form a support for the flange. The performance adjustment device 3 consists of a concrete bead 4 and an internal prestressing system 5 .

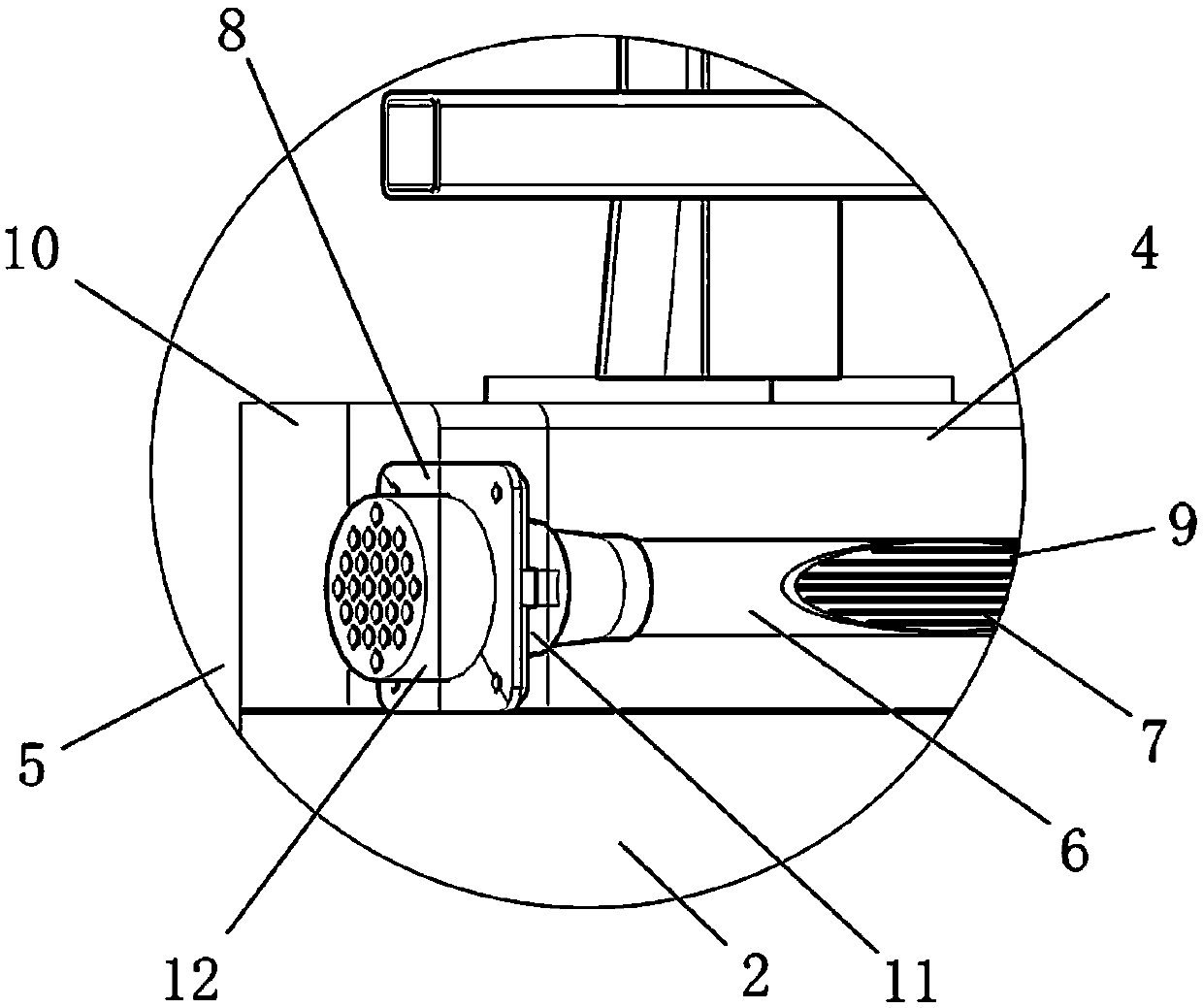

[0030] see image 3 , The prestressing system 5 includes a prestressing pipeline 6 , a prestressing steel beam 7 , a prestressing anchor 8 , grouting inside the pipeline 9 , and anchoring concrete 10 . The prestressed anchor 8 includes an anchor seat 11 and an anchor plate 12 .

[0031] see image 3 , before the concrete bead 4 is poured, the pre-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com