Thallium ion treating agent and thallium-containing wastewater treating method

A technology for ion treatment and wastewater treatment, applied in the direction of neutralization water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of complex operation, long time-consuming, low efficiency, etc., to protect the environment and water Resources, low production costs, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

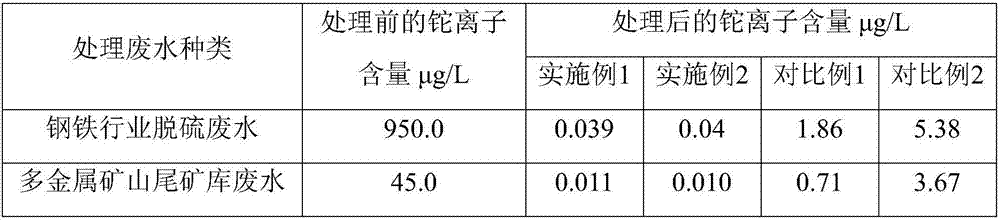

Embodiment 1

[0025] The thallium ion treating agent provided in this embodiment includes by mass percentage: 10% zinc sulfate, 14% magnesium sulfate, 10% polyaluminum chloride, 19% calcium hypochlorite, 8% sodium hydroxide, 17% calcium oxide, activated carbon 8% and ferrous sulfate 14%.

[0026] The preparation method of the thallium ion treatment agent is as follows: under normal temperature and normal pressure, first weigh the raw materials according to the proportion, then add zinc sulfate, magnesium sulfate, polyalumina, ferrous sulfate and activated carbon into the mixer, start Stir the motor, then slowly add calcium hypochlorite, sodium hydroxide and calcium oxide in sequence, and then stir and mix for 60 minutes to obtain the finished product. Then, the finished product of the thallium ion treatment agent is sampled and tested, and bagged after passing the test. After bagging, it is transported to the finished product warehouse for storage and standby, and production records are mad...

Embodiment 2

[0040] The thallium ion treating agent provided in this embodiment includes by mass percentage: 11.5% of zinc sulfate, 15.5% of magnesium sulfate, 10% of polyaluminum chloride, 20.5% of calcium hypochlorite, 4% of sodium hydroxide, 16.5% of calcium oxide, activated carbon 8% and ferrous sulfate 14%.

[0041] The preparation method of the thallium ion treating agent of this embodiment is the same as that of Embodiment 1.

[0042] Use the thallium ion treatment agent to treat the iron and steel industry desulfurization wastewater with a thallium ion content of 950.0 μg / L and a pH of 6.0 to 7.0, specifically according to the following steps:

[0043] (1) On-site pre-test: Take 200mg, 300mg, 400mg, 500mg and 600mg of thallium ion treatment agents and add them to five beakers containing 100ml of desulfurization wastewater from the iron and steel industry respectively. After standing for 40 minutes, detect the supernatant in the five beakers thallium ion content. The test result i...

Embodiment 3

[0055] The thallium ion treating agent provided in this embodiment includes by mass percentage: 22% of zinc sulfate, 13% of magnesium sulfate, 7% of polyaluminum chloride, 18% of calcium hypochlorite, 4% of sodium hydroxide, 16% of calcium oxide, activated carbon 10% and ferrous sulfate 10%.

[0056] The preparation method of the thallium ion treating agent of this embodiment is the same as that of Embodiment 1.

[0057] Use the thallium ion treatment agent to treat the desulfurization wastewater in the iron and steel industry with a thallium ion content greater than 500 μg / L. The treatment steps are basically the same as in Example 1, except that the dosage of the thallium ion treatment agent, Concentration, reaction time and other parameters are adjusted according to the thallium ion content of the wastewater and the results of the on-site pre-test, and the thallium ion content in the treated purified water can be reduced to below 0.05 μg / L.

[0058] Using the thallium ion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com