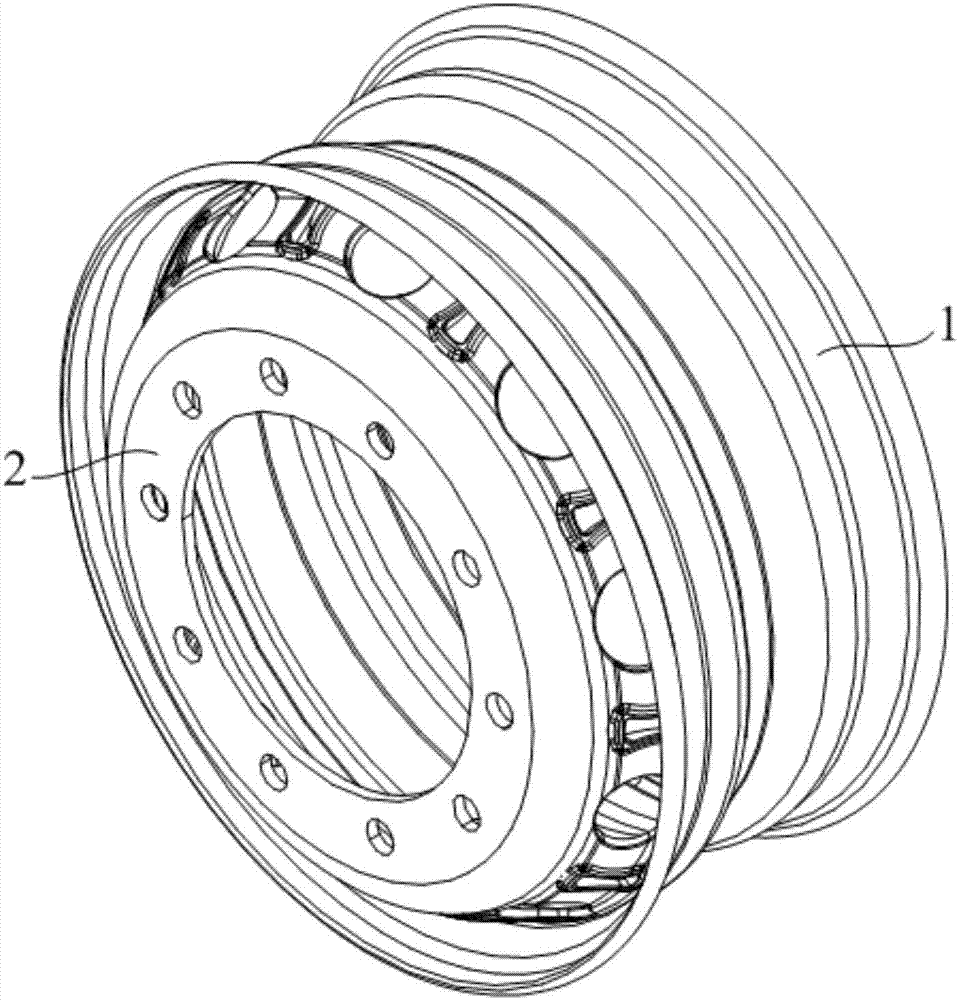

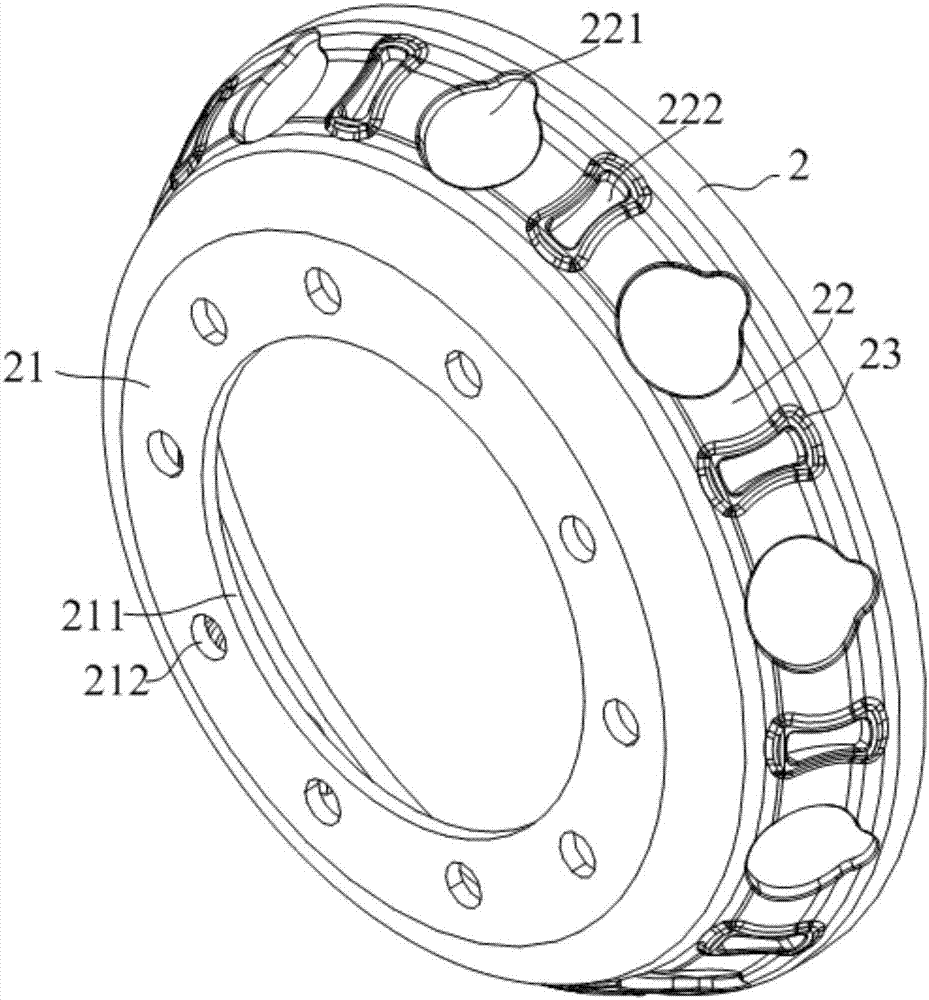

Lightweight wheel with flanging irregular hole spoke

A special-shaped hole and lightweight technology, which is applied in the direction of spoke-plate wheels, wheels, vehicle parts, etc., can solve the problems of wheel spoke deformation, air hole cracking, unsafety, etc., to increase the wheel load, increase service life, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, the present invention provides a light-weight wheel with flanged and special-shaped hole spokes. It can be seen from the title of this patent that the light-weight wheel spoke is what the inventor mainly embodies and explains. The inventor responds to the present The big environment and future demands have reduced the weight of the original bulky and high-energy-consuming wheel spokes. What is lightweight? Lightweight means to reduce the weight of the original wheel itself, thereby reducing the need to apply the wheel to the car. energy consumption. Reduce the weight of the original wheel, there will be many chain reactions, for example, whether its own stiffness and strength can meet the requirements, or whether the processing technology meets the standards for producing lightweight wheel spokes, for the inventor's designed lightweight To quantify the wheel spokes, the original spoke thickness of 14mm is designed into a spoke thickness of 9.0-11.0mm. It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com