Wood structure reinforcing process based on vacuum negative-pressure method

A vacuum negative pressure and wood structure technology, which is applied in the field of wood structure reinforcement technology based on vacuum negative pressure method, can solve the problems of environmental pollution, debonding of cemented interface, dripping, etc., and achieves no environmental pollution, low cost, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

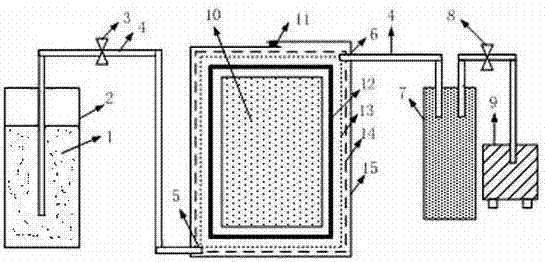

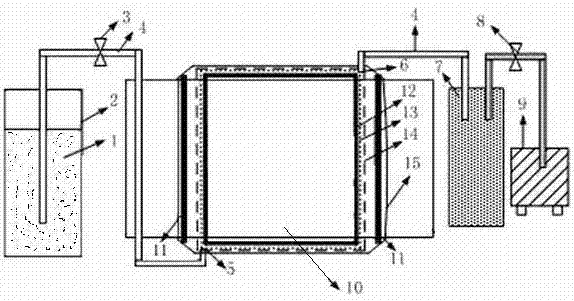

[0016] A wood structure reinforcement process based on vacuum negative pressure method, comprising the following steps:

[0017] 1. Clean the surface of the wooden structure, and paste the sealant 11 around the area of the wooden structure 10 to be reinforced;

[0018] 2. Spread glass fiber cloth 12 according to the principle that the area of the wood structure 10 to be reinforced is thick and the side is thin, and then lay polyester release cloth 13 and diversion vinyl mesh cloth 14 in sequence;

[0019] 3. Lay the vacuum bag 15 again, the vacuum bag 15 is connected with the sealant 11 around the area of the wood structure 10 to be reinforced, and set the resin injection port 5 and the air extraction port 6 to check the airtightness of the vacuum bag 15 to ensure that the vacuum bag 15 The airtightness of the separated area is good;

[0020] 4. According to the ambient temperature, add 1-3% curing agent to the vinyl resin 1 and stir evenly, and put it into the resin co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com