A feeding system for a composite sandwich panel production line

A feeding system and production line technology, applied in metal processing, etc., can solve problems such as limited production line speed, low automation level, and production line speed reduction, so as to improve production line stability and product qualification rate, and reduce operator load , reduce the effect of one investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings.

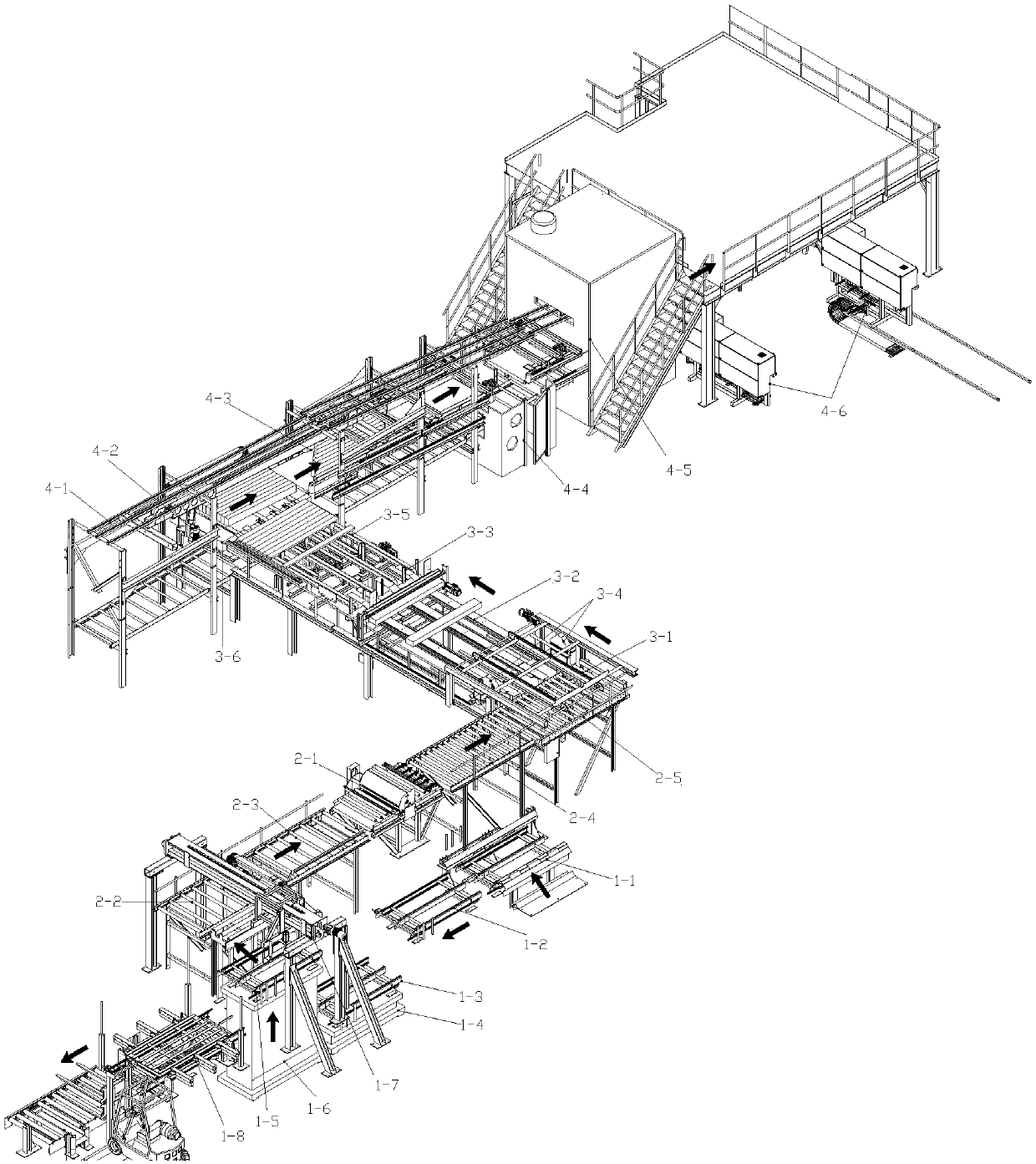

[0017] like figure 1 As shown, the feeding system is sequentially provided with a rock wool slab feeding and conveying device 1, a rock wool slab cutting device 2, a rock wool slat turning and conveying device 3, and a rock wool slat bridging edge milling device 4 from front to back. .

[0018] The rock wool board stack feed conveying device 1 is composed of a board stack feeding conveyor 1-1, a buffer conveyor 1-2, a hydraulic lifting platform 1-3, a chain conveyor 1-4, and another hydraulic lifting platform 1- 5. Another chain conveyor 1-6, a pusher device 1-7, a pallet pusher 1-8 and a pallet output roller table 1-9, the left side of the pallet feeding conveyor 1-1 There is a buffer conveyor 1-2, a chain conveyor 1-4 is provided on the left side of the buffer conveyor 1-2, a hydraulic lifting platform 1-3 is provided above the chain conveyor 1-4, and a chain conveyor 1-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com