Wheat germ steamed bun and production process thereof

A technology of wheat germ and wheat germ powder, which is applied in the direction of food ingredients as taste improvers, food science, and yeast-containing food ingredients, etc., can solve the problems of imperfect research and utilization, and achieve small recovery changes, increased brightness, and specific volume. The effect of small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

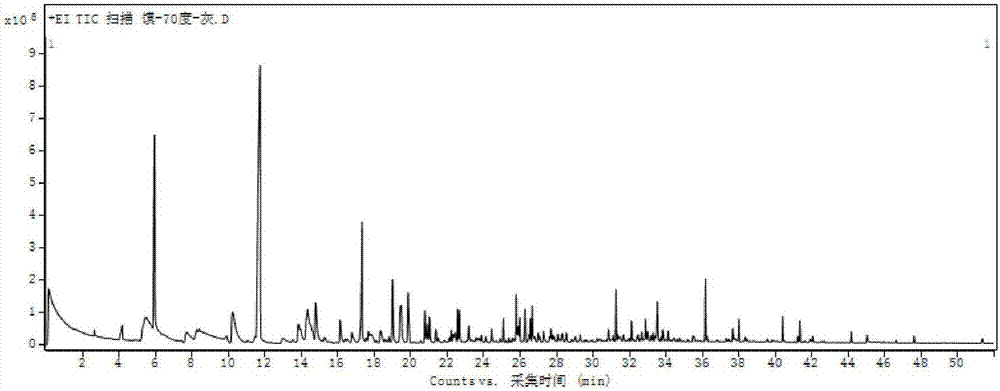

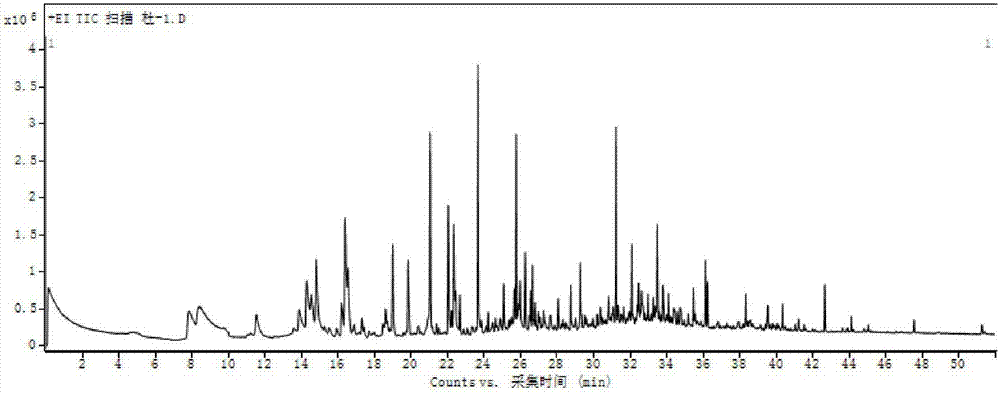

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further analyzed and illustrated through specific examples below.

[0033] The wheat germ steamed bread, its raw materials are composed as follows according to parts by mass:

[0034] Main ingredients: 100-130 parts of wheat flour, 2-6 parts of wheat germ powder, 3-7 parts of soybean flour, 9-12 parts of corn flour;

[0035] Accessories: 2-5 parts of sugar, 0.8 parts of yeast, 1-3 parts of salt, 42-50 parts of water.

[0036] The fineness of the basic wheat flour is 80-120 mesh, and the fineness of the wheat germ powder is 80-120 mesh.

[0037] The manufacturing process of the wheat germ steamed bread comprises the following steps:

[0038] 1. Mixing: Pour the raw materials in the main ingredients into the container, and mix them evenly to get the mixed powder;

[0039] 2. Dissolving yeast: dissolving yeast in water at 20-30°C to obtain yeast liquid;

[0040] 3. Dissolving sugar and salt: Dissolve sugar and sal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com