Saddle of lead-acid storage battery and preparation method thereof and lead-acid storage battery

A lead-acid battery and saddle technology is applied in the field of lead-acid battery saddle and preparation, which can solve the problems of short circuit of positive and negative contacts at the contact point, increased stress on the battery cover, inability to deform the plastic bracket, etc. Battery life, inexpensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

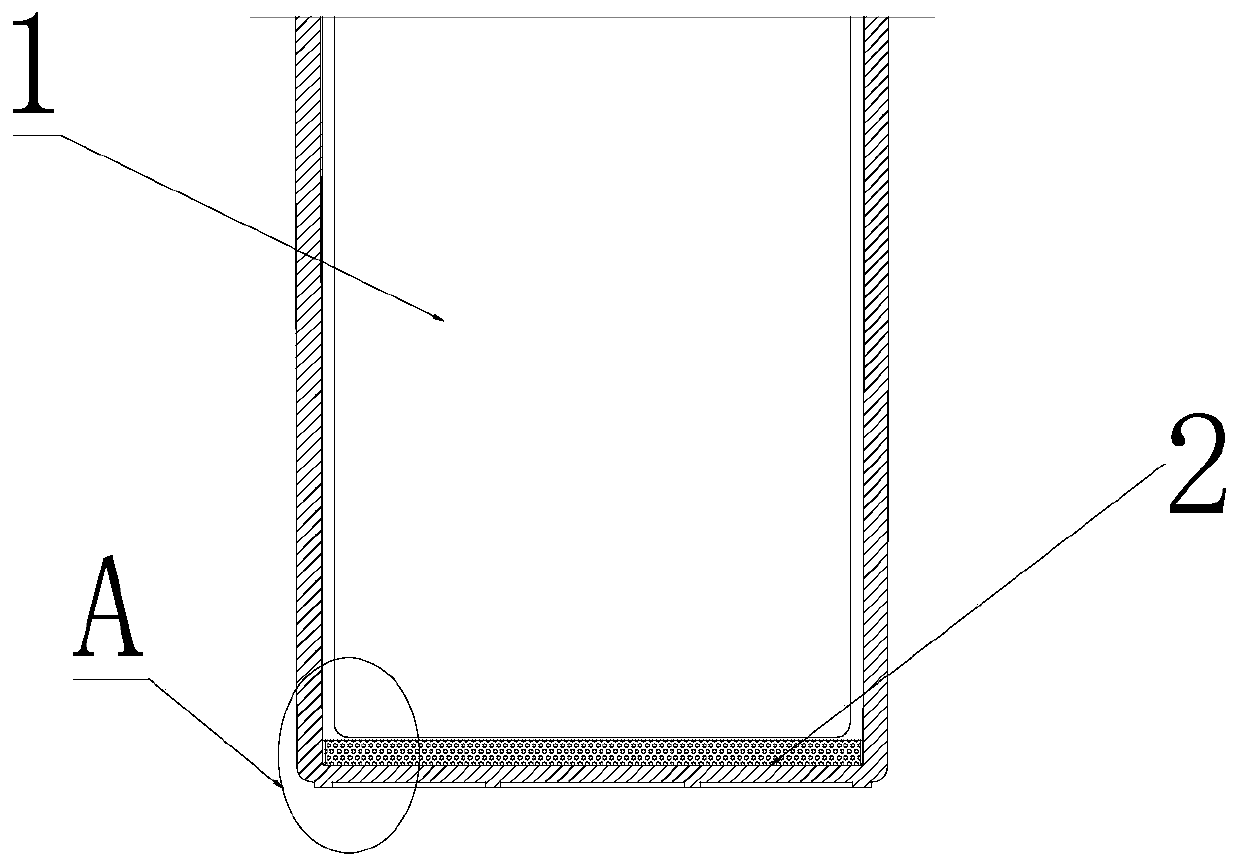

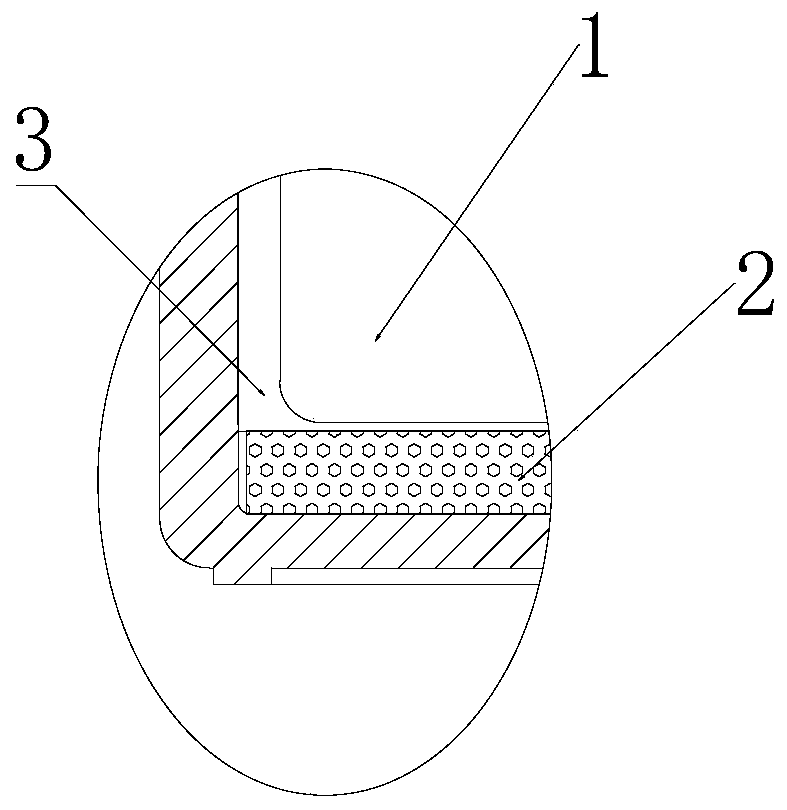

Image

Examples

Embodiment 1

[0050] Weigh each component by the following parts by mass:

[0051] SiO 2 The average particle size of the particles is 23 μm, 1000 parts;

[0052] The mass fraction is 20% silica sol colloidal solution, 200 parts;

[0053] SiO 2 The average particle size of the particles is 0.3 μm, 20 parts;

[0054] Adjust the pH of the mixture to 6 with dilute sulfuric acid.

[0055] Preparation:

[0056] (1) Pour 20% silica sol colloidal solution into the blender first, and carry out high-speed stirring at a speed of 2000rp / min to shear the particle size silica sol colloidal solution, and slowly add 0.3 μm SiO to the blender 2 . Stir for 5min.

[0057] (2) Use a dropper to add 30% sulfuric acid to adjust the pH value of the solution to 6.

[0058] (3) SiO with an average particle size of 23 μm 2 Add it into the solution, and stir for 3 minutes at a rotation speed of 100 rp / min.

[0059] (4) Weigh the appropriate mixture and pour it into the bottom of the battery tank, and smooth...

Embodiment 2

[0063] Weigh each component by the following parts by mass:

[0064] SiO 2 The average particle size of the particles is 23 μm, 1000 parts;

[0065] The mass fraction is 40% silica sol colloidal solution, 300 parts;

[0066] SiO 2 The average particle size of the particles is 0.3 μm, 45 parts;

[0067] Adjust the pH of the mixture to 6 with dilute sulfuric acid.

[0068] Preparation:

[0069] (1) Pour 40% silica sol colloidal solution into the blender first, and carry out high-speed stirring at a speed of 2000rp / min to shear the particle size silica sol colloidal solution, and slowly add SiO with an average particle size of 0.3 μm into the blender2 . Stir for 5min.

[0070] (2) Use a dropper to add sulfuric acid to adjust the pH value of the solution to 7.

[0071] (3) SiO with an average particle size of 23 μm 2 Add it into the solution, and stir for 3 minutes at a rotation speed of 100 rp / min.

[0072] (4) Weigh the appropriate mixture and pour it into the bottom of...

Embodiment 3

[0075] Weigh each component by the following parts by mass:

[0076] SiO 2 The average particle size of the particles is 23 μm, 1000 parts;

[0077] The mass fraction is 20% silica sol colloidal solution, 200 parts;

[0078] SiO 2 The average particle size of the particles is 0.3 μm, 20 parts;

[0079] Polyacrylamide polymer water-absorbing resin with a molecular weight of 6 million to 25 million, 0.2 parts;

[0080] Adjust the pH of the mixture to 6 with dilute sulfuric acid.

[0081] Preparation:

[0082] (1) First mix polyacrylamide with deionized water and stir until completely dissolved.

[0083] (2) Pour 20% silica sol colloidal solution into the blender, and carry out high-speed stirring at a speed of 2000rp / min to shear the particle size silica sol colloidal solution, and slowly add 0.3 μm SiO to the blender 2 . Stir for 5min.

[0084] (3) Use a dropper to add 30% sulfuric acid to adjust the pH value of the solution to 6.

[0085] (4) SiO with an average part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com