A display and an optical sheet therefor

A display and optical sheet technology, applied in the field of optical sheets, can solve problems such as low peak value, poor chroma specification, and poor color rendering, and achieve the effect of improving light extraction efficiency and chroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments to further understand the purpose, solution and effect of the present invention, but it is not intended to limit the scope of protection of the appended claims of the present invention.

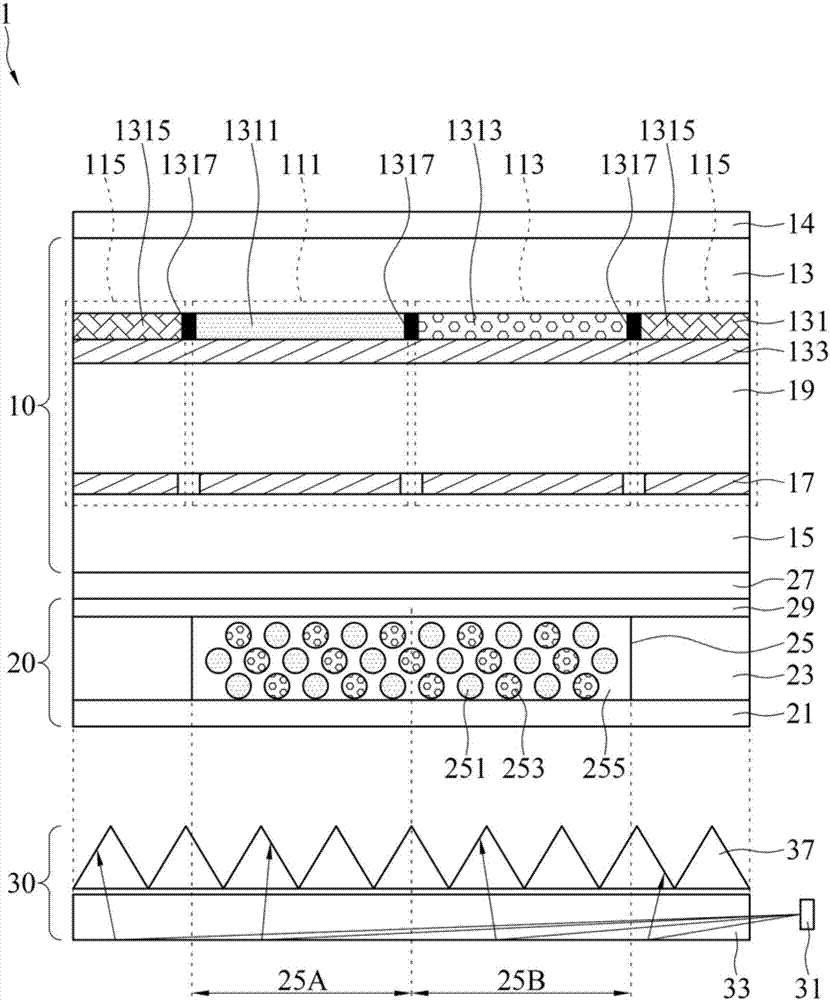

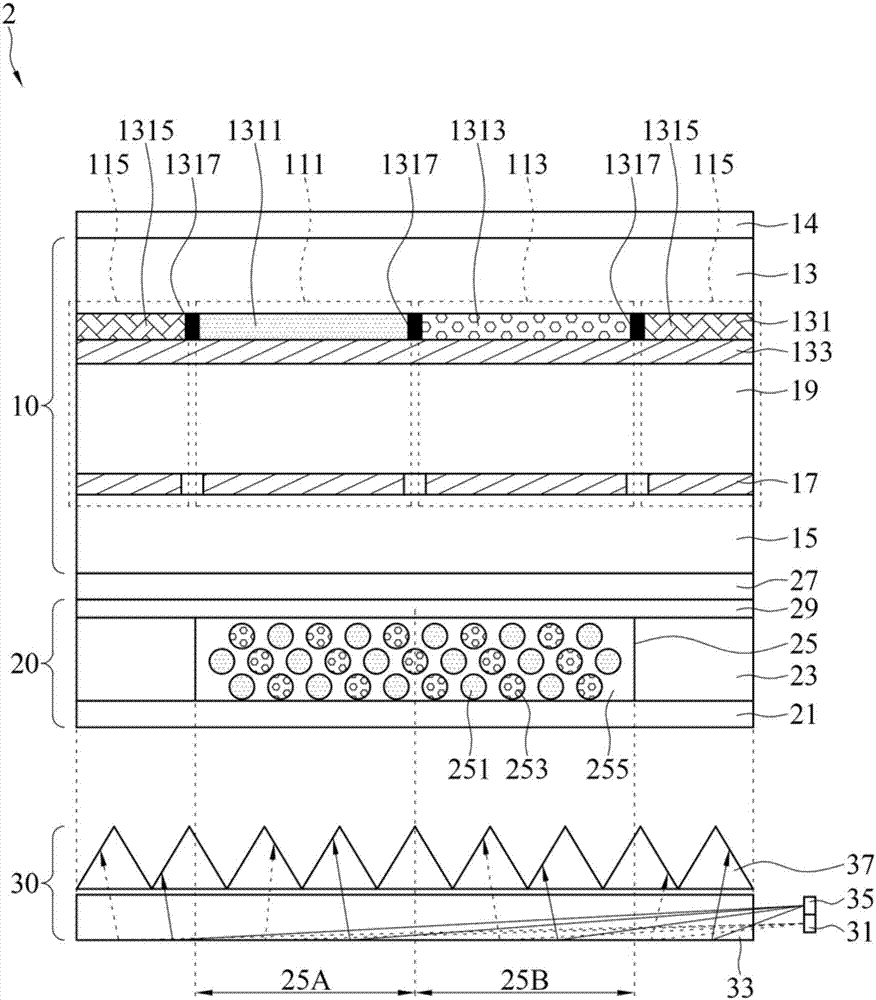

[0044] figure 1 It is a schematic cross-sectional view of the display of the first embodiment. refer to figure 1 , the display 1 includes a display panel 10 , an optical sheet 20 and a backlight module 30 . The optical sheet 20 is located between the display panel 10 and the backlight module 30 .

[0045] The display panel 10 includes a plurality of first-color sub-pixels 111 , a plurality of second-color sub-pixels 113 and a plurality of third-color sub-pixels 115 . The backlight module 30 includes a blue light source 31 .

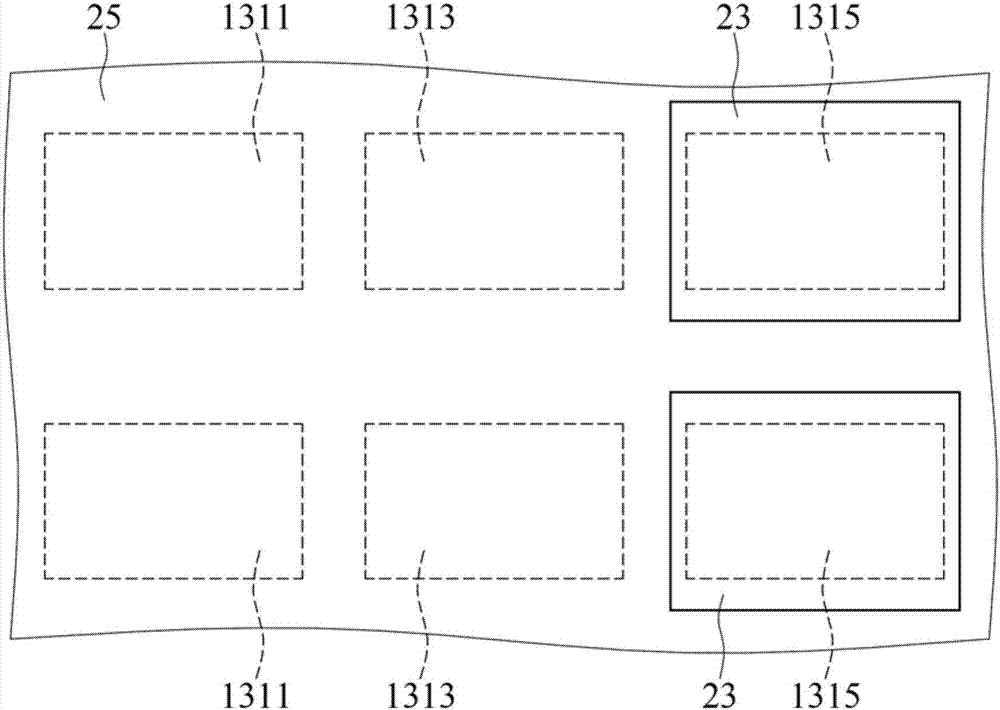

[0046] The optical sheet 20 includes a substrate 21 , a plurality of transparent protrusions 23 , and a pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com