Circuit board ageing vehicle

A circuit board, aging car technology, applied in electronic circuit testing, printed circuit testing, measuring electricity and other directions, can solve the problems of high maintenance costs, stable product performance, labor costs, etc., to improve the efficiency of aging testing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

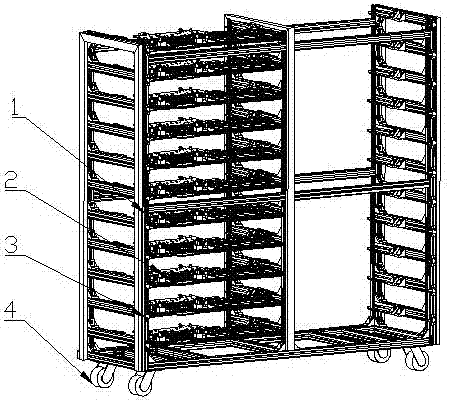

[0007] A circuit board aging vehicle, which is composed of 1 frame, 2 aging tools, 3 spring pins, and 4 casters. On the corner support column, 4 casters are installed at the bottom of the four corners of the rack.

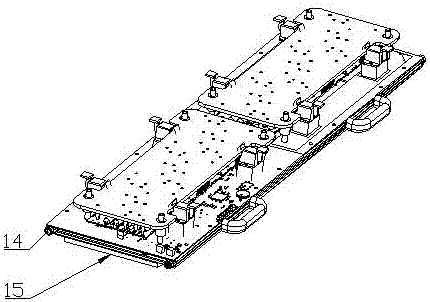

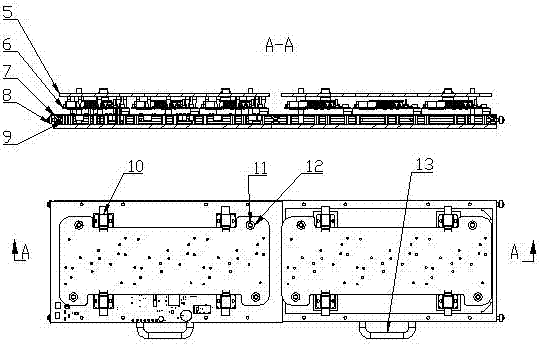

[0008] 2 The aging chemical equipment consists of 5 circuit board pressure plates, 6 circuit boards, 7 probe test boards, 8 rolling bearings, 9 tooling racks, 10 rack buckles, 11 guide shafts, 12 guide bushings, 13 handles, 14 screws, and 15 backing plates The composition is characterized in that: 5 circuit board pressing plates and 12 guide bushings are fixed together, 6 circuit boards are fixed between 5 circuit board pressing plates and 7 probe test boards, 7 probe test boards are fixed on 9 tooling racks, 8 The rolling bearing is fixed on the 9 tooling frame through 14 screws, the 10 rack buckle is fixed on the 7 probe test board, 11 the guide shaft is fixed on the 15 backing plate after passing through the 7 probe test board, and the 15 backing plate is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com