Preparation method for nanometer microelectrolysis material used for removing tetracycline pollutants

A technology of tetracyclines and micro-electrolysis, which is applied in the direction of water pollutants, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of high treatment cost, unoptimistic treatment status, incomplete mineralization, etc., and achieve rapid response, Quick removal effect, highly reactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

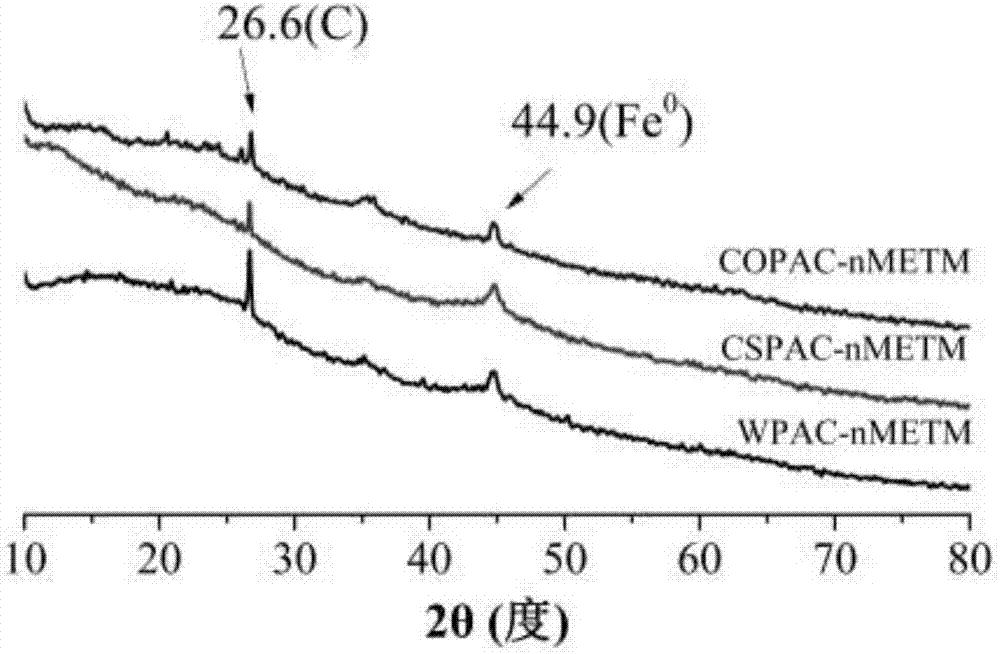

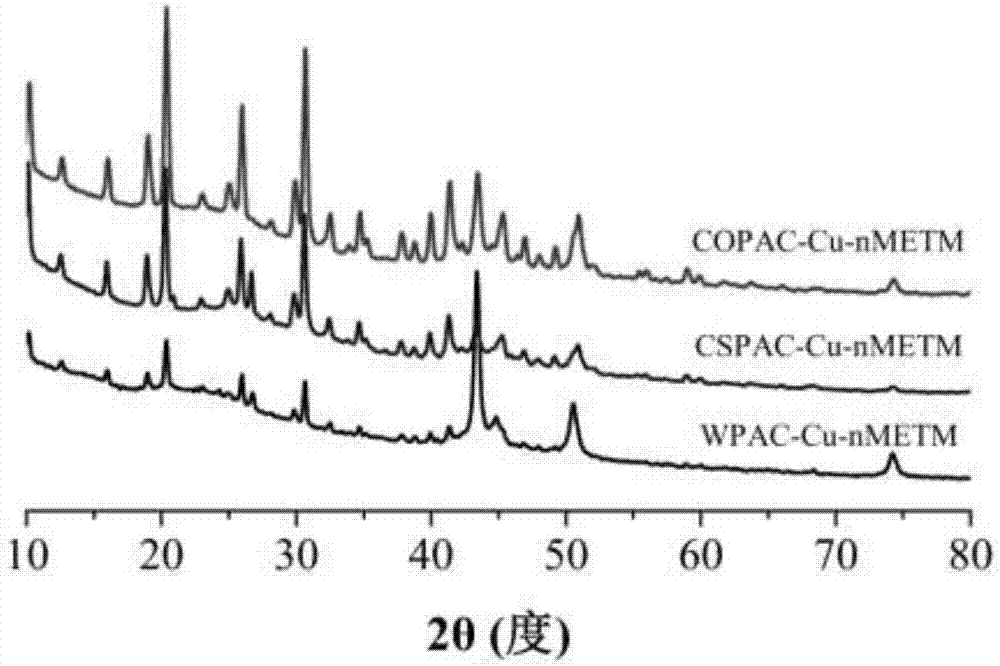

Embodiment 1

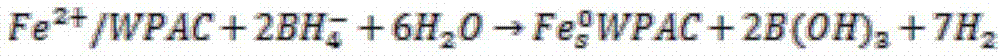

[0028] Step 1: Pass WPAC through a 100-mesh sieve, soak in ultrapure water for 24 hours, put it in an oven at 120°C, and dry it for 2 hours before use. FeSO 4 ·7H 2 O the solid is ground and pulverized, and after passing through a 100-mesh sieve, it is set aside.

[0029] Step 2: take by weighing 3.268g of sodium borohydride (NaBH 4 ) into a beaker, and dissolve it with ultrapure water to prepare a 5mol / L sodium borohydride solution, which is named as preformed solution A.

[0030] Step 3: Weigh 10.000g of FeSO 4 ·7H 2 The O solid was dissolved in a 150mL 4 / 1 (v / v) ethanol / water mixed solution in a beaker, then placed in an ultrasonic cleaner for 10min, and then 0.864g (FeSO 4 ·7H 2 The mass ratio of O to activated carbon is 1:2) WPAC is added to the above mixed solution, and then ultrasonicated for 15 minutes, so that WPAC and the mixed solution are fully mixed, and the prefabricated solution B is prepared.

[0031] Step 4: Slowly add the prefabricated solution A solut...

Embodiment 2

[0039] Step 1: Pass CSPAC through a 100-mesh sieve, soak it in ultrapure water for 24 hours, put it in an oven at 120°C, and dry it for 2 hours before use. FeSO 4 ·7H 2 O The solid is ground and pulverized, and passed through a 100-mesh sieve for subsequent use.

[0040] Step 2: take by weighing 3.268g of sodium borohydride (NaBH 4 ) into a beaker, and dissolve it with ultrapure water to prepare a 5mol / L sodium borohydride solution, which is named as preformed solution A.

[0041] Step 3: Weigh 10.000g of FeSO 4 ·7H 2 The O solid was dissolved in a 150mL 4 / 1 (v / v) ethanol / water mixed solution in a beaker, then placed in an ultrasonic cleaner for 10min, and then 0.864g (FeSO 4 ·7H 2 The molar ratio of O to activated carbon is 1:2) CSPAC is added to the above mixed solution, and then ultrasonicated for 15 minutes, so that WPAC and the mixed solution are fully mixed, and the prefabricated solution B is prepared.

[0042] Step 4: Slowly add the prefabricated solution A solu...

Embodiment 3

[0048] Step 1: Pass COPAC through a 100-mesh sieve, soak it in ultrapure water for 24 hours, put it in an oven at 120°C, and dry it for 2 hours before use. FeSO 4 ·7H 2 O The solid is ground and pulverized, and passed through a 100-mesh sieve for subsequent use.

[0049] Step 2: take by weighing 3.268g of sodium borohydride (NaBH 4 ) into a beaker, and dissolve it with ultrapure water to prepare a 5mol / L sodium borohydride solution, which is named as preformed solution A.

[0050] Step 3: Weigh 10.000g of FeSO 4 ·7H 2 The O solid was dissolved in a 150mL 4 / 1 (v / v) ethanol / water mixed solution in a beaker, then placed in an ultrasonic cleaner for 10min, and then 0.864g (FeSO 4 ·7H 2 The molar ratio of O to activated carbon is 1:2) COPAC is added to the above mixed solution, and then ultrasonicated for 15 minutes, so that WPAC and the mixed solution are fully mixed, and the prefabricated solution B is prepared.

[0051] Step 4: Slowly add the prefabricated solution A solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com