Efficient vertical type pneumatic separation equipment and application technology thereof

A vertical, air separation technology, applied in application, solid separation, separation of solids from solids by air flow, etc., can solve the problems of material moisture content and large flake ratio, the number of air separation bins, the number of times and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

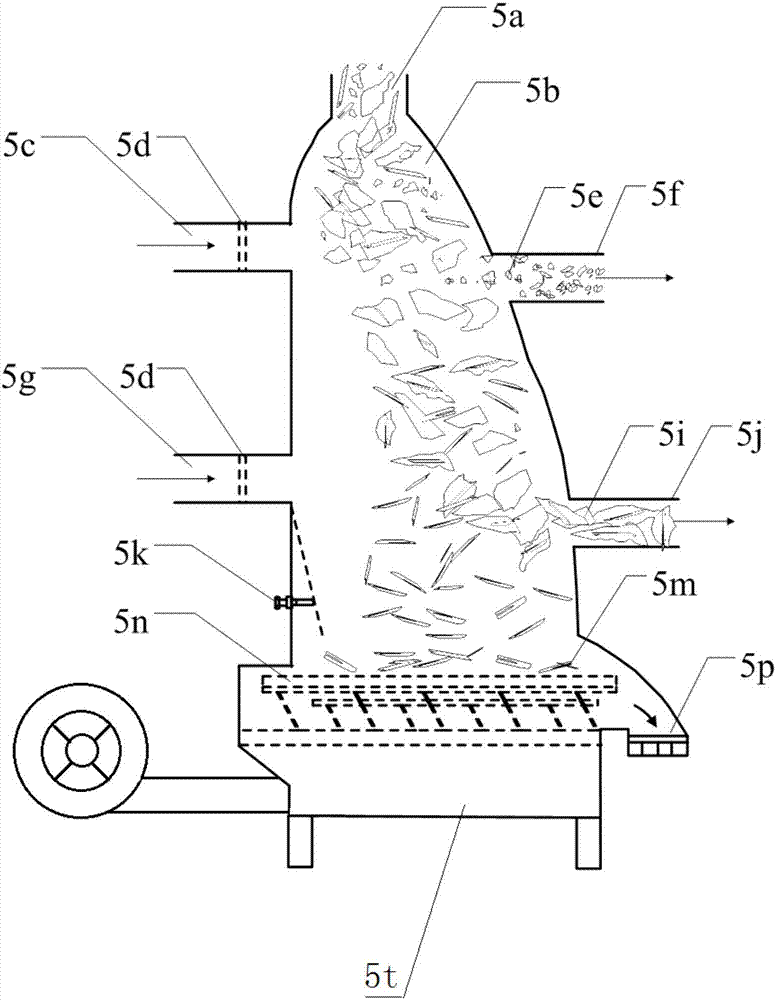

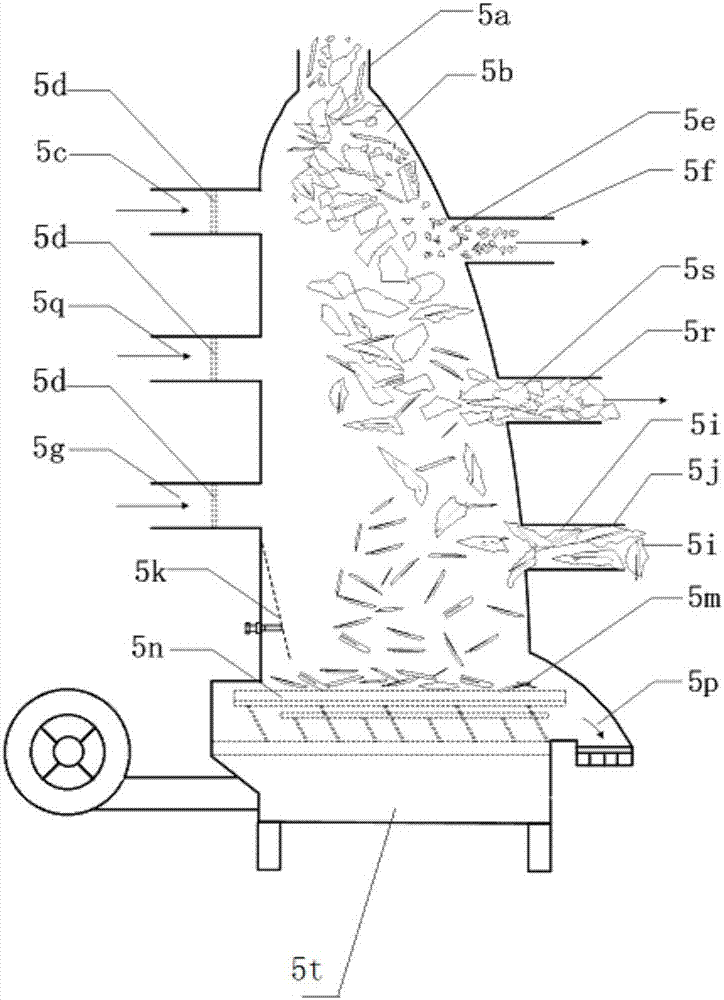

[0040] Embodiment 1: A kind of high-efficiency vertical air separation equipment, including support 1a, bin body 2a and its air bin 5b, placed in the vibrating conveyor trough at the bottom of the air bin 5b, the conveyor belt located under the vibrating conveyor trough and the conveyor belt The stalk material outlet 5p at the end is opened at the feed inlet 5a at the top of the air bin 5b, and two positive pressure air ducts distributed vertically at high and low positions are provided on one side wall of the air bin 5b. Two negative pressure feed pipes distributed vertically at high and low positions are provided on the side wall opposite to the face where the air conveying pipe is located. The horizontal height of the air delivery pipe 5g is higher than the low negative pressure feed pipe 5j; the outlet air pressure of the high positive pressure air delivery pipe 5c is lower than the outlet air pressure of the low positive pressure air delivery pipe 5g, and the section of th...

Embodiment 2

[0053] Embodiment 2: The high-efficiency and energy-saving vertical air separation equipment of the present invention is applied in the following order: scraper feeder 1, bin feeder 2, and proportional feeder 3a are connected in series with each other by conveyor belts and connected to the first stage The leaf-threshing units 3 are connected, wherein the first-stage leaf-threshing unit 3 is composed of four parallel-connected leaf-threshing machines, and each leaf-threshing machine of the first-stage leaf-threshing unit 3 is respectively connected to a double positive pressure machine through a conveyor belt 4 Wind sub-machine 5 connection.

[0054] The discharge port of each double positive pressure air sub-machine in the first-stage wind sub-unit is connected to the conveyor belt 9 through the negative pressure pipeline 8 and connected to the second-stage leaf-threshing unit 14, and the second-stage leaf-threshing unit 12 passes through the conveyor belt 13 It is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com