Instant unloading drop bar of a true triaxial testing machine

A testing machine and true three-axis technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems that affect the expected effect, the drop speed of the dowel bar cannot reach the instantaneous unloading of the load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

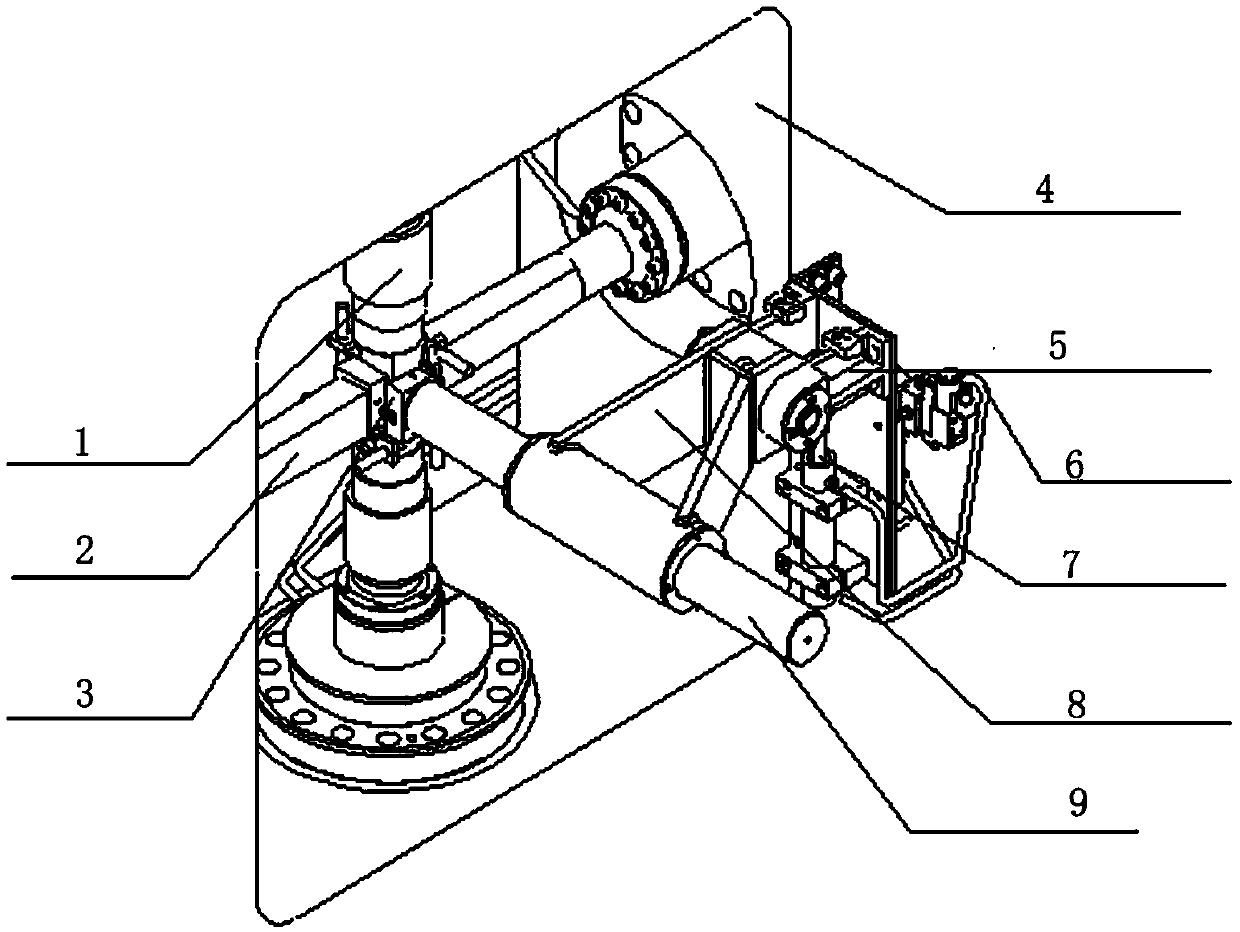

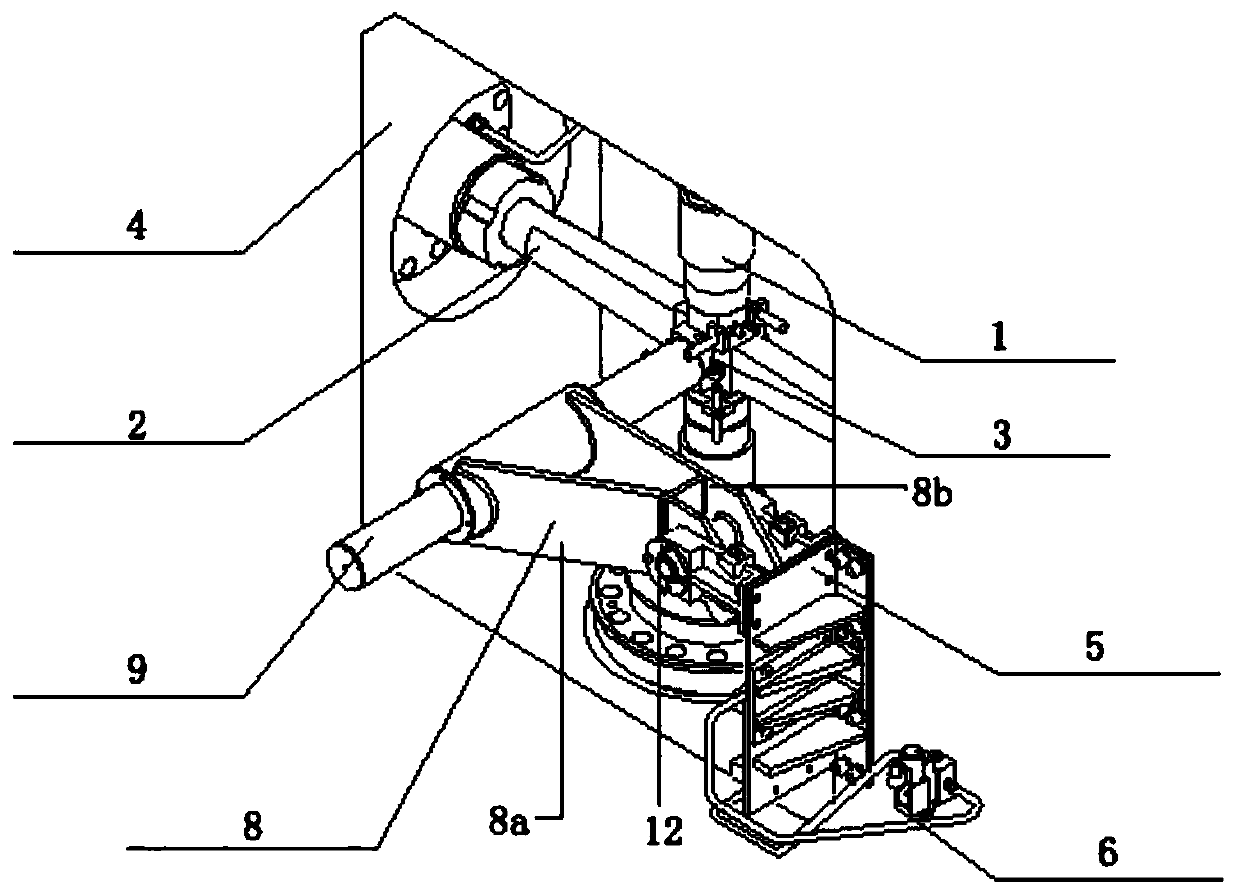

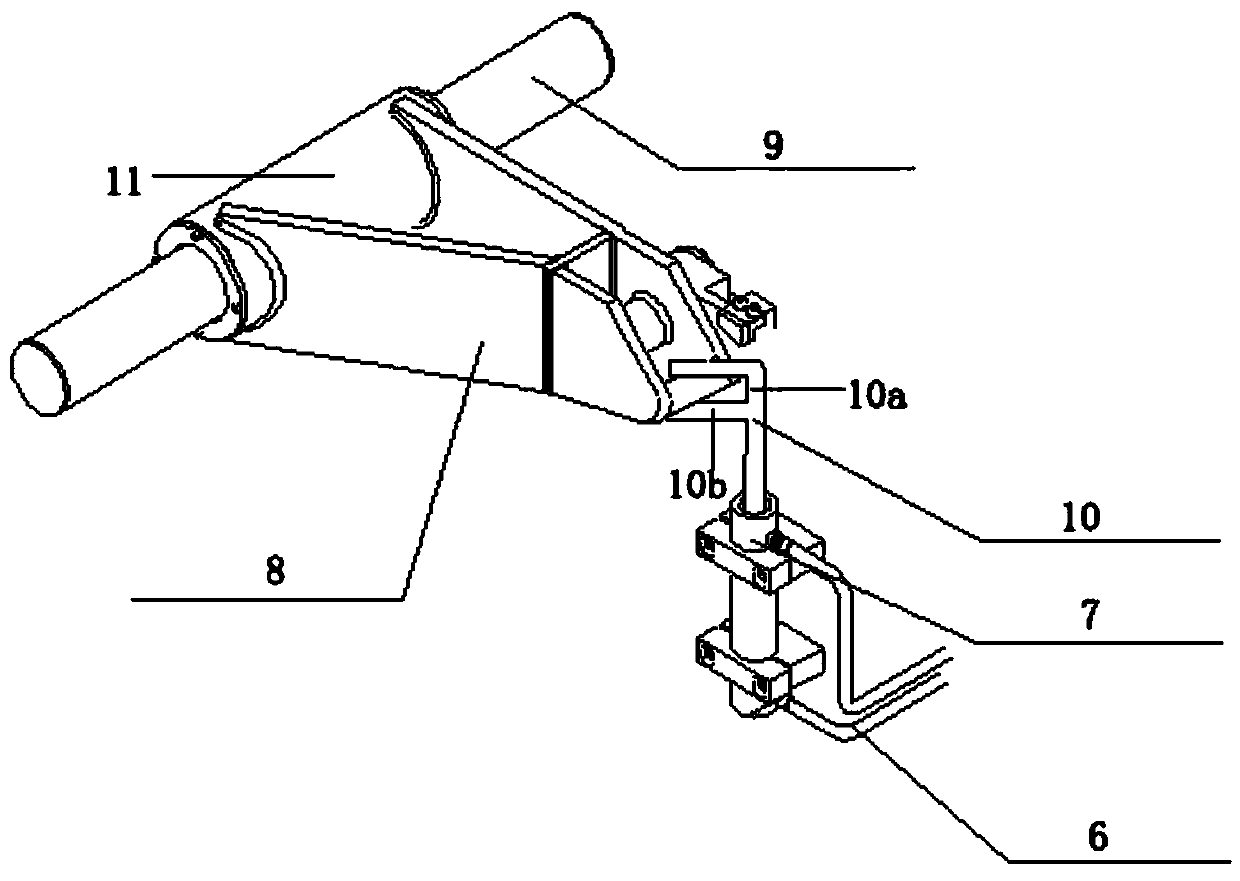

[0018] As shown in Figures 1, 2 and 3, a true triaxial testing machine instantaneous unloading drop bar includes four parts: a dowel bar 9, a transmission shaft 8, a hydraulic bar 7, and a fixed frame 5. The fixed frame 5 fixes the entire mechanism on the testing machine. , the upper end of the hydraulic rod 7 is an F-shaped member (ie image 3 The indicated position of the upper part of the hydraulic rod 7 belongs to the upper part of the hydraulic rod), the oil pressure of the hydraulic oil delivery pipe 6 is used as the power to move up and down quickly, and the transverse rod 10b of the F-shaped member on the upper part of the hydraulic rod 7 drives the short arm of the transmission shaft 8b moves up and down, so that the long arm 8a of the transmission shaft moves up and down more quickly. The longitudinal rod 10a of the F-shaped component is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com