Pipe rack prefabrication and assembly construction method

A construction method and prefabricated assembly technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of difficult construction and large occupation of the construction site, and achieve the effect of small quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

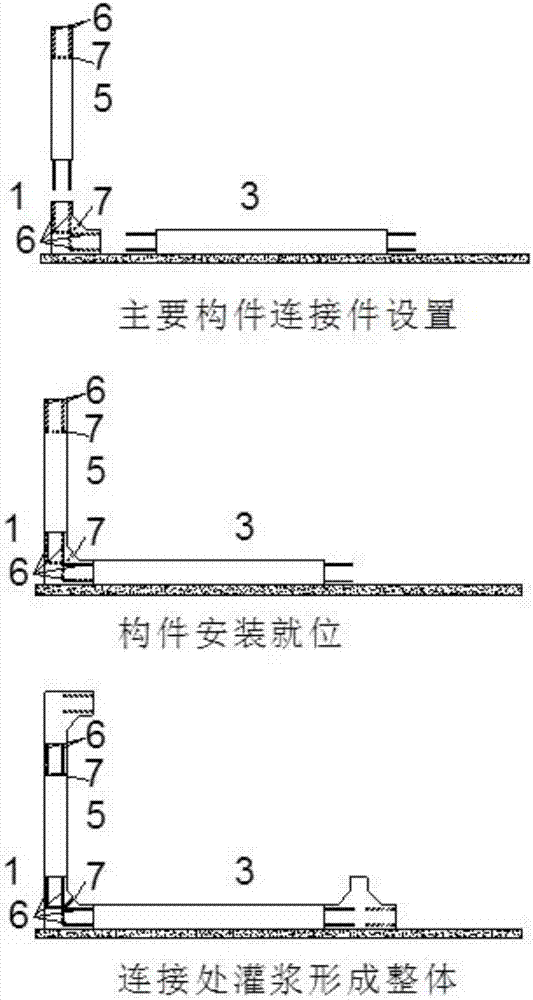

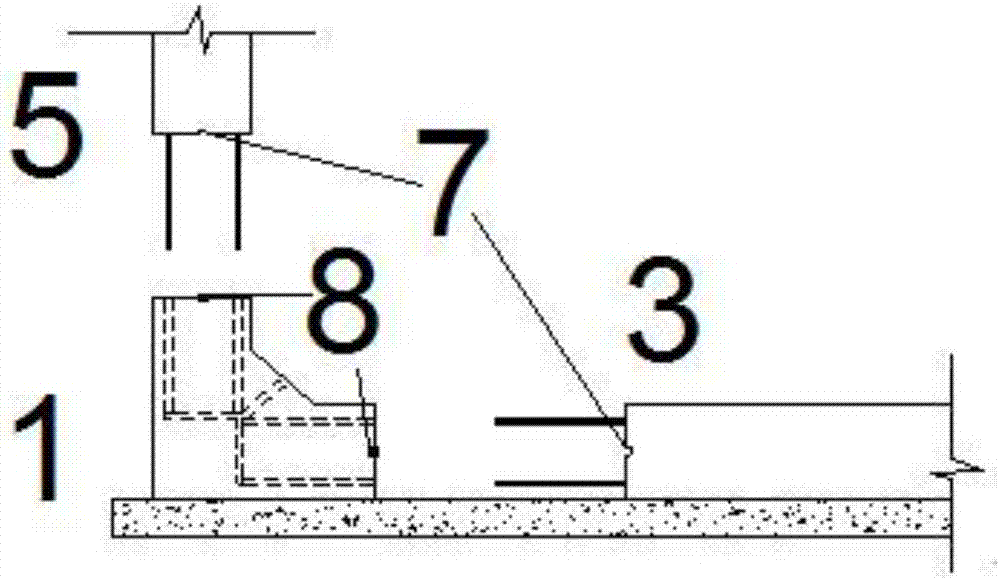

[0044] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

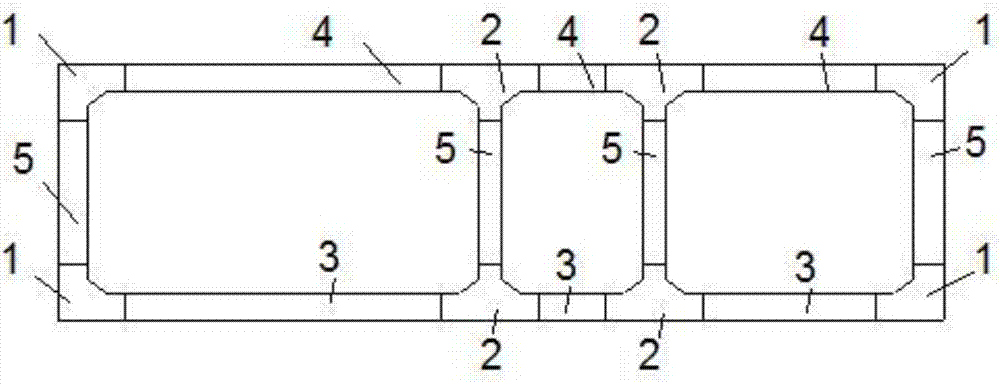

[0045] As attached figure 1 As shown, the decomposition design of the pre-assembled components of the pipe gallery is shown to form an exploded view of the sectional components of the pipe gallery.

[0046] The section of the pipe gallery is decomposed and designed for the pre-assembled structure, and the “L”-shaped corner beams are designed according to the structural forces of each component: 1: used for corners at the outer wall of the pipe gallery; “T”-shaped corner beams 2: used for pipes Tuck corners at the inner wall of the gallery; bottom plate member 3: used for the bottom of the pipe ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com