A warm-mixed asphalt thin-layer overlay structure of waste cement concrete recycled aggregate and its construction method

A technology of cement concrete and recycled aggregates, which is applied to cohesive pavement, roads, buildings, etc. on site, and can solve the problem of rapid temperature drop in hot-mix asphalt thin-layer overlay construction and the decline in road performance of warm-mix asphalt mixture , hot mix asphalt mixture energy consumption and other problems, to improve the comprehensive utilization rate, reduce energy consumption and exhaust emissions, improve the effect of cooling too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

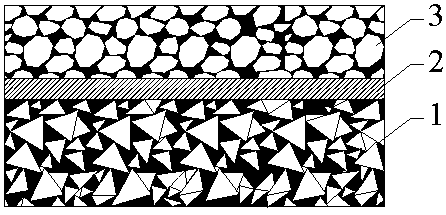

[0047] Such as figure 1 As shown, the waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay structure of the present invention sequentially includes a warm-mix rubber asphalt bonding layer (2) on the original pavement structure (1) and waste cement concrete Recycled aggregate warm mix asphalt thin layer overlay (3).

[0048] Among them, there is no thickness requirement for the original pavement structure (1) and the warm-mix rubber asphalt bonding layer (2), and the thickness of the warm-mix asphalt thin-layer overlay (3) of waste cement concrete recycled aggregate is 2.5 cm.

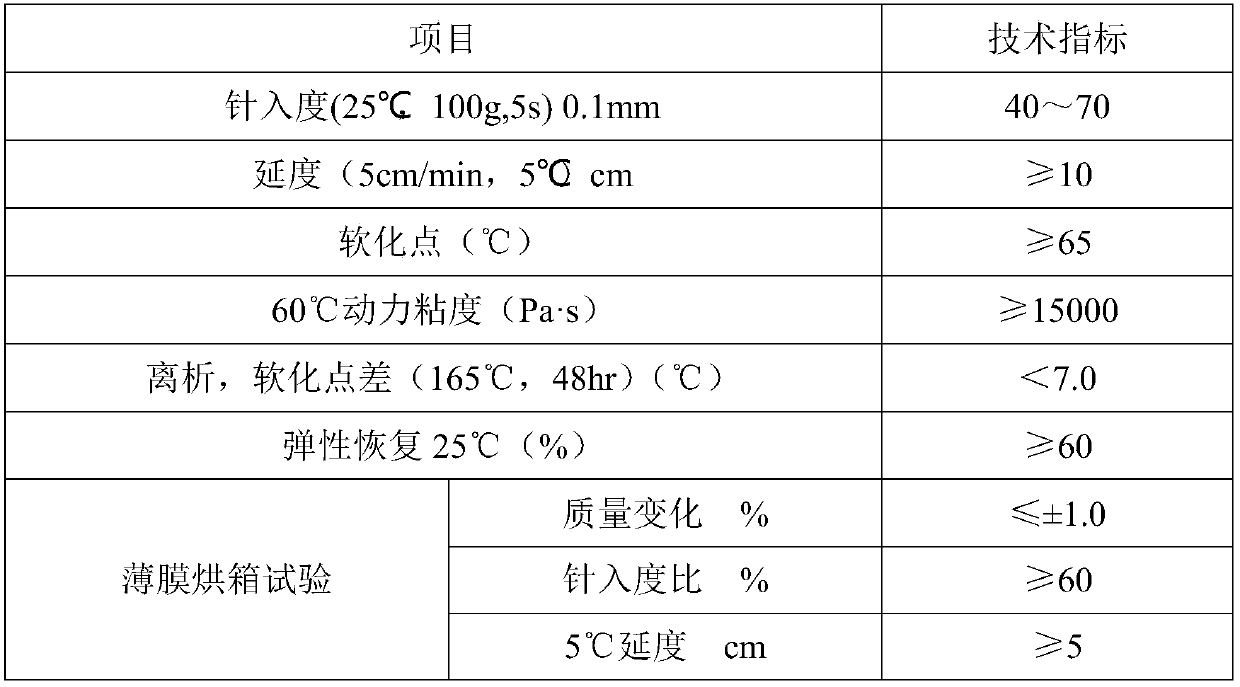

[0049] The material of the warm-mix rubber asphalt bonding layer (2) is warm-mix rubber powder modified asphalt, and the parts by weight of the rubber powder-modified asphalt and asphalt warm-mix agent are: 94 parts of rubber powder-modified asphalt, asphalt Warm mixing agent 6 parts.

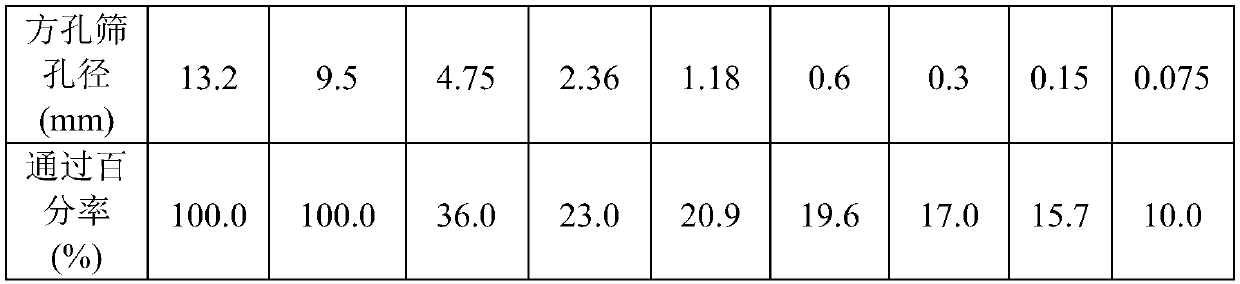

[0050] The ore gradation of the waste cement concrete recycled aggregate warm-mix asphalt th...

Embodiment 2

[0071] The waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay structure of this embodiment and the preparation method of the waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay are the same as in Example 1, only the waste cement concrete recycled aggregate The materials of the warm-mix asphalt thin-layer overlay (3) and the construction methods of the waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay structure are different.

[0072] In this embodiment, the mineral material gradation of the waste cement concrete recycled aggregate warm-mix asphalt thin layer overlay (3) is shown in Table 4.

[0073] Table 4 Mineral gradation composition of waste cement concrete recycled aggregate warm mix asphalt mixture in Example 2

[0074]

[0075] The raw materials of waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay (3) described in this embodiment are as follows:

[0076] (1) The ...

Embodiment 3

[0083] The waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay structure of this embodiment and the preparation method of the waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay are the same as in Example 1, only the waste cement concrete recycled aggregate The materials of the warm-mix asphalt thin-layer overlay (3) and the construction methods of the waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay structure are different.

[0084] In this embodiment, the mineral aggregate gradation of the waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay (3) is shown in Table 5.

[0085] Table 5 Mineral gradation composition of waste cement concrete recycled aggregate warm mix asphalt mixture in Example 3

[0086]

[0087] The raw materials of waste cement concrete recycled aggregate warm-mix asphalt thin-layer overlay (3) described in this embodiment are as follows:

[0088] (1) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com