A kind of fragrance type cigarette paper, its preparation method and application

A technology of cigarette paper and fragrance type, applied in the field of fragrance type cigarette paper, can solve the problems such as the influence of cigarette aroma, and achieve the effects of improving the moisturizing feeling of cigarettes, weakening the irritation of the throat, and increasing the irritation of the throat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

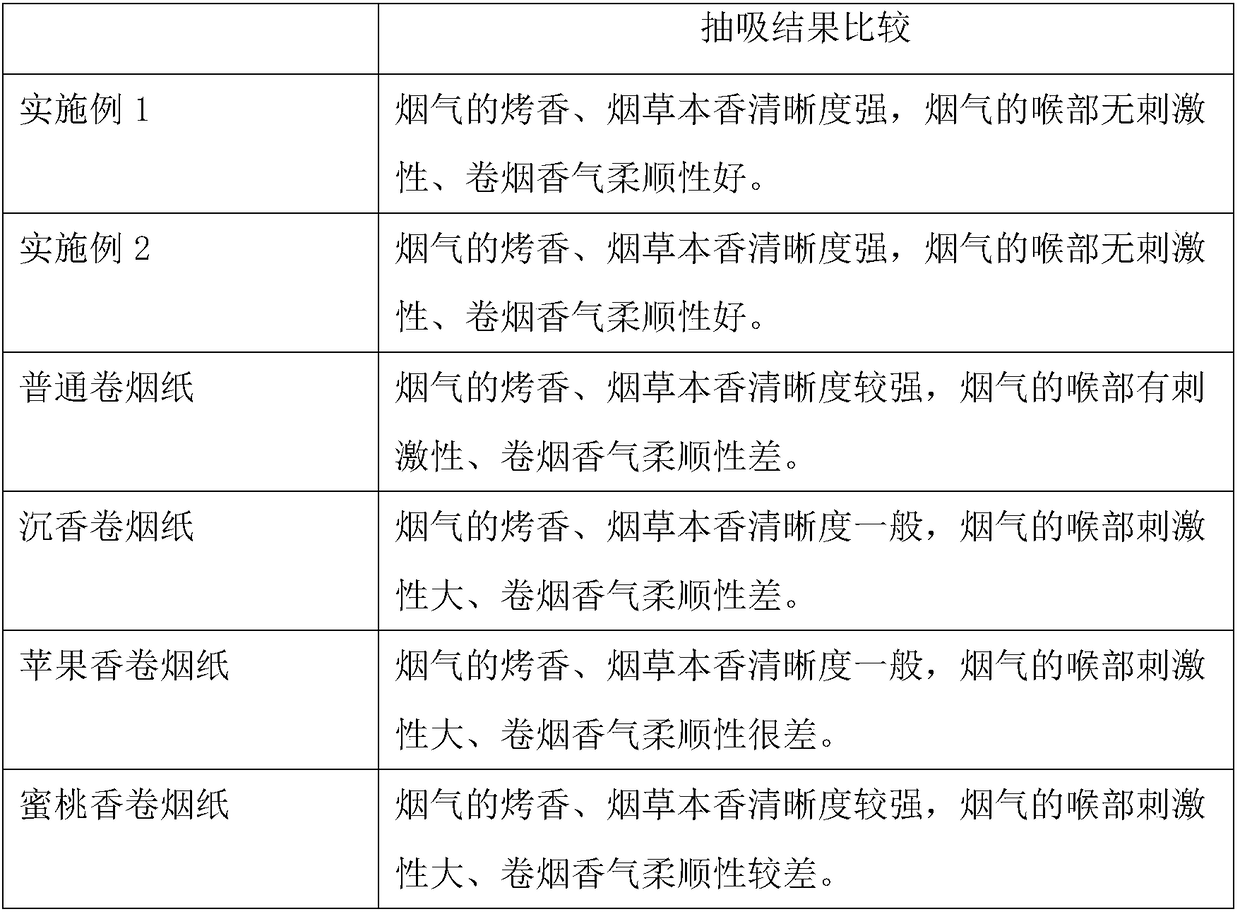

Examples

preparation example Construction

[0023] (1) Preparation of sweet orange extract: crushing the fruit, stem and leaves of sweet orange, extracting with boiling water, filtering off the residue, and concentrating to obtain the initial cream of tobacco extraction; after the initial cream is extracted by 75wt% alcohol After filtering off the residue, the obtained sweet orange extract is concentrated to obtain the sweet orange extract;

[0024] (2) Mix the sweet orange extract, plant-type stabilizer, sweetening substance and combustion accelerant into water in proportion and mix evenly;

[0025] (3) Spray the mixture in step (2) on the surface of ordinary cigarette paper at 40° C., and dry it to obtain the light-flavor cigarette paper.

Embodiment 1

[0026] Embodiment 1: the preparation of fragrance type cigarette paper

[0027] (1) After crushing the fruit and stem leaves of the sweet orange, use boiling water as the extraction solvent to extract and filter off the residue, and concentrate the extract to obtain the initial extract of tobacco. The initial extract is added to an alcohol precipitation tank Carry out alcohol extraction with alcohol, after the residue is filtered out after alcohol extraction, the sweet orange extract will be obtained after the sweet orange extract is concentrated;

[0028] (2) Mix 3KG of sweet orange extract, 1.0Kg of plant-type stabilizer, 1KG of sweetening substance, and 1.0Kg of potassium citrate and sodium citrate with a mass ratio of 1:2 to 3:1. water and mix well;

[0029] (3) Spray the mixture in step (2) on the surface of 1 t of ordinary cigarette paper at 40° C., and dry to obtain the light-flavor cigarette paper.

Embodiment 2

[0030] Embodiment 2: the preparation of fragrance type cigarette paper

[0031] (1) After crushing the fruit and stem leaves of the sweet orange, use boiling water as the extraction solvent to extract and filter off the residue, and concentrate the extract to obtain the initial extract of tobacco. The initial extract is added to an alcohol precipitation tank Carry out alcohol extraction with alcohol, after the residue is filtered out after alcohol extraction, the sweet orange extract will be obtained after the sweet orange extract is concentrated;

[0032] (2) Mix 2KG of sweet orange extract, 0.80Kg of vegetable stabilizer, 3KG of sweetening substance, and 0.5Kg of potassium citrate and sodium citrate combustion accelerant with a mass ratio of 1:2 to 3:1. water and mix well;

[0033] (3) Spray the mixture of step (2) on the surface of 1 t of ordinary cigarette paper at 40° C., and dry to obtain the light-flavor cigarette paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com