Large smoke exhaust super strong oil stain cleanser and preparing method

A technology for oil cleaning agent and range hood, applied in the field of cleaning agents, can solve the problems of burning the motor, increasing the working load of the motor, darkening the stainless steel cover, etc., and achieves faster oil removal, faster oil removal, and no hard oil. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A super strong oily dirt cleaning agent for large range hoods, the specific preparation process of which is as follows:

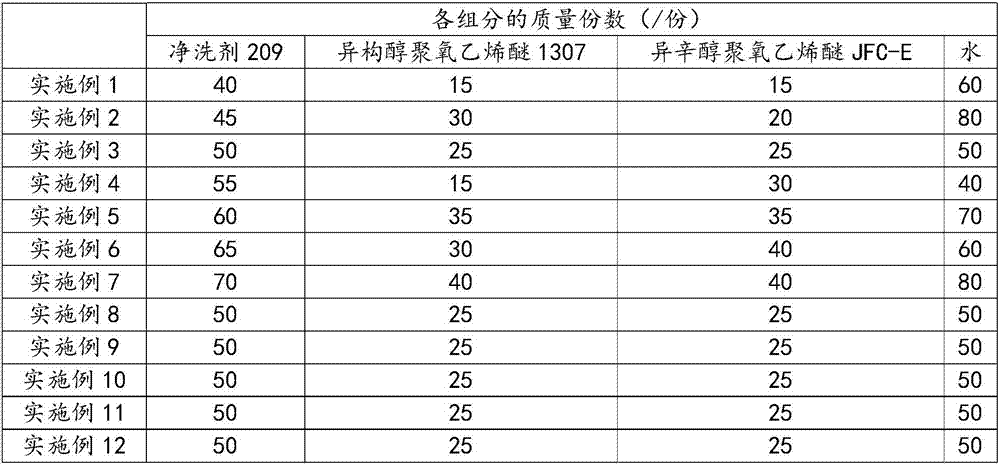

[0020] (1) Weigh cleaning agent 209, isomeric alcohol polyoxyethylene ether 1307, isooctyl alcohol polyoxyethylene ether JFC-E, water according to the mass parts shown in Table 1;

[0021] Table 1 embodiment 1-10 each component mass parts number weigh detailed list

[0022]

[0023] (2) Heat the water weighed in step (1) to 60-100° C. for later use. The specific heating temperature is shown in Table 2;

[0024] Table 2 embodiment 1-7 heating temperature is clear

[0025] Example Heating temperature / ℃ 1 82 2 65 3 80 4 90 5 100 6 95 7 70

[0026] (3) Put detergent 209 into the container first, then put isomer alcohol polyoxyethylene ether 1307 into the container, stir evenly, then put isooctyl alcohol polyoxyethylene ether JFC-E into the container, stir Evenly, finally put the heated water in step...

Embodiment 2-7

[0028] The specific dosage of each component is shown in Table 1, the specific preparation process is the same as in Example 1, and the specific heating temperature of water in step (2) is shown in Table 2.

Embodiment 8

[0030] A super strong oily dirt cleaning agent for large range hoods, the specific preparation process of which is as follows:

[0031] (1) Weigh cleaning agent 209, isomeric alcohol polyoxyethylene ether 1307, isooctyl alcohol polyoxyethylene ether JFC-E, water according to the mass parts shown in Table 1;

[0032] (2) Heat the water weighed in step (1) to 60°C for subsequent use;

[0033] (3) Put detergent 209 into the container first, then put isomer alcohol polyoxyethylene ether 1307 into the container, stir evenly, then put isooctyl alcohol polyoxyethylene ether JFC-E into the container, stir Evenly, finally put the heated water in step (2) into the container, and the detergent 209, isomeric alcohol polyoxyethylene ether 1307, and isooctyl alcohol polyoxyethylene ether JFC-E can be used after completely dissolving in water , the time required for complete dissolution is about 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com