Pressure-sensitive adhesive and preparation method thereof

A technology of pressure-sensitive adhesives and tackifiers, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problem of low dielectric constant of adhesives, achieve low production process requirements, and improve comprehensive performance , a wide range of effects

Active Publication Date: 2017-07-07

SUZHOU FINESET MATERIAL TECH CO LTD

View PDF1 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, with the rapid development of electronic products, acrylic resin adhesives still have certain limitations

For example, in specific applications, adhesives are required to have a lower dielectric constant (usually Dk is required to be 2 to 3 at 1 kHz to 1 MHz), but traditional acrylic resins have double bonds and high dielectric constants, making it difficult to meet this requirement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

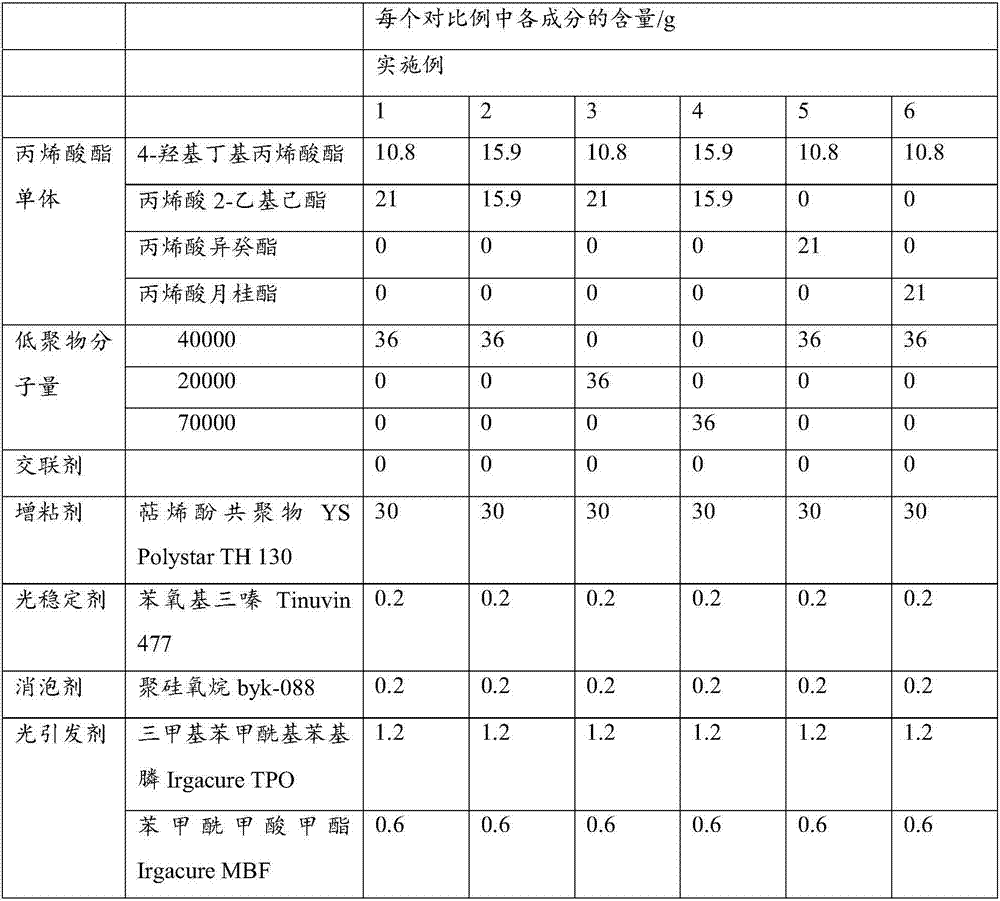

Embodiment 1 to 6

[0070] Prepare the adhesive

[0071] The formula is shown in Table 1.

[0072] Table 1

[0073]

[0074] Note: The oligomers described in Table 1 are acrylate prepolymers.

[0075] The preparation method is as follows:

[0076] The above components are fully stirred and mixed, and vacuumized to obtain a liquid pressure-sensitive adhesive composition, which can be directly applied to a substrate and cured by UV irradiation.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides an optical acrylate pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive has a relatively low dielectric constant under the condition of 1kHz-1MHz, has the advantages of high peel strength, high transmittance and the like, and is wider in application prospect. The pressure-sensitive adhesive is formed by polymerizing one or more acrylate monomers and an oligomer under the action of a photoinitiator; each acrylate monomer is acrylic saturated alcohol ester or alkyl acrylic saturated alcohol ester; the weight ratio of the acrylate monomers is 10% or more, preferably 15% or more and more preferably20% or more; the molecular weight of the oligomer is20000 or more; and the oligomer is selected from one or more of an acrylic prepolymer, an epoxy prepolymer, an organosilicone prepolymer, a polyurethane prepolymer, a polyether prepolymer, a polyhydroxyl polyolefin oligomer, a polybutadiene prepolymer and a fluorine-modified prepolymer.

Description

technical field [0001] The invention relates to the field of optical display, in particular to an optical pressure-sensitive adhesive for bonding display devices and a preparation method thereof. Background technique [0002] With the wide application and rapid development of optical displays, the requirements for optical pressure-sensitive adhesives are getting higher and higher. Acrylic resin is one of the commonly used pressure-sensitive adhesives. It is widely used because of its many advantages: 1. High adhesion to transparent materials such as PET optical film or glass; 2. Colorless and transparent appearance and good weather resistance 3. No additives are required, and the formula is simple; 4. Pressure-sensitive adhesives that meet various performance requirements can be prepared by copolymerization and cross-linking. [0003] However, with the rapid development of electronic products, acrylic resin adhesives still have certain limitations. For example, in specific...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09J4/02C09J4/06C09J11/06C09J11/08

CPCC09J4/06C09J11/06C09J11/08

Inventor 泽登纯一冈琦哲也陈维姜云陈田安高昂杨春强江华邹学良周玉波

Owner SUZHOU FINESET MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com