A laser direct structuring material with good comprehensive properties and its preparation method

A technology of laser direct structuring and comprehensive performance, applied in the field of laser direct structuring materials and their preparation, can solve the problems of inability to meet the requirements of material performance, failure to pass the 100-grid test, slow electroless plating, etc., to achieve a performance balance, Wide design space and improved salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

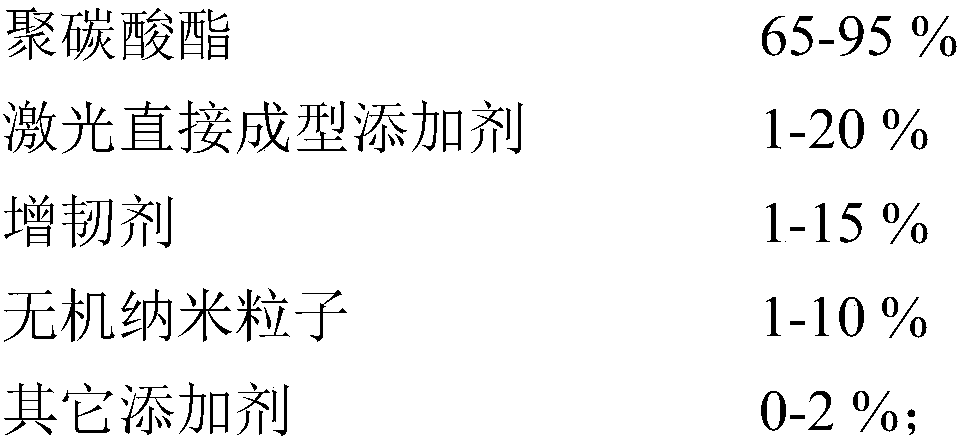

[0033] The total amount of raw materials is 10kg, and by weight percentage, the components are as follows:

[0034] Polycarbonate 87.2wt%

[0035] LDS additive 3wt%

[0036] Toughener 4wt%

[0037] Inorganic nanoparticles 5wt%

[0038] Other additives 0.8wt%

[0039] In this embodiment, the polycarbonate adopts the polycarbonate containing bisphenol A structure, including two kinds: one kind of polycarbonate has an MFR of 8g / min at 300°C and 1.2Kg, and a weight average molecular weight of 24000. It is 42wt%; the MFR of a kind of polycarbonate at 300 ℃, 1.2Kg is 18g / min, the weight-average molecular weight is 19500, and the weight percentage used is 45.2wt%.

[0040] In this embodiment, there are two kinds of LDS additives: LDS-1 (basic copper phosphate) and LDS-2 (tin pyrophosphate), and the weight percentage of the two in the total raw material is 3wt%.

[0041] In this example, the toughening agent (IM) is a silicone core-shell polymer (using Mitsubishi Rayon Metablen S...

Embodiment 7~11

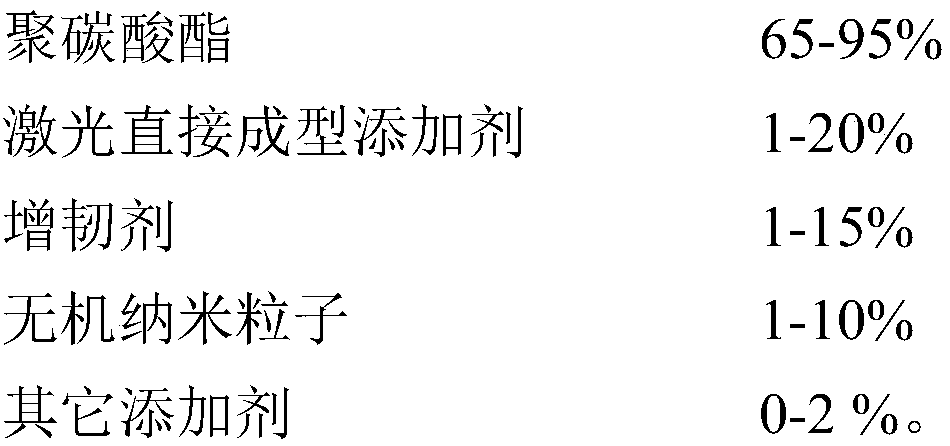

[0054] The total amount of raw materials is 10kg, by weight percentage, including the following components:

[0055] Polycarbonate 85wt%

[0056] LDS additive 6wt%

[0057] Toughener 5wt%

[0058] Inorganic nanoparticles 3wt%

[0059] Other additives 1wt%

[0060] The polycarbonate in this embodiment is the polycarbonate containing bisphenol A structure, including two kinds: a kind of polycarbonate is at 300 ℃, the MFR of 1.2Kg is 8g / min, and the weight average molecular weight is 24000, and the mass parts used It is 40wt%; a kind of polycarbonate is 18g / min at 300 ℃, MFR of 1.2Kg, weight average molecular weight is 19500, and the used mass fraction is 45wt%.

[0061] In this embodiment, there are two kinds of LDS additives: LDS-1 (basic copper phosphate) and LDS-3 (zinc stannate). In the total raw materials, the weight percentage of the two is 6wt%.

[0062] In this embodiment, the toughening agent (IM) is methyl methacrylate-butadiene-styrene terpolymer (model is DOWEXL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com