Cutting device for automobile window glass

A technology for car window glass and cutting device, applied in glass cutting device, glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of fragile glass, achieve the effect of balanced force, improve accuracy and reduce breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

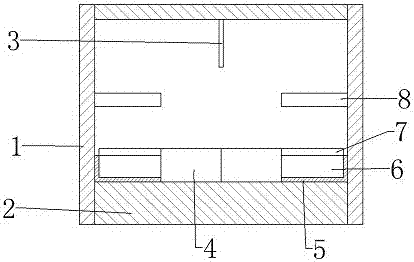

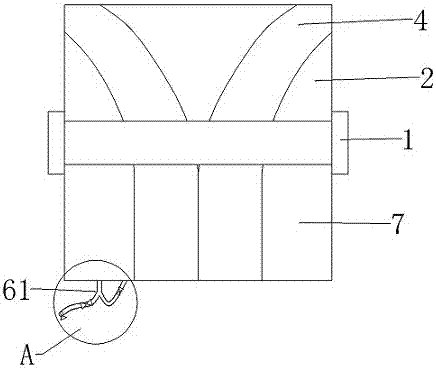

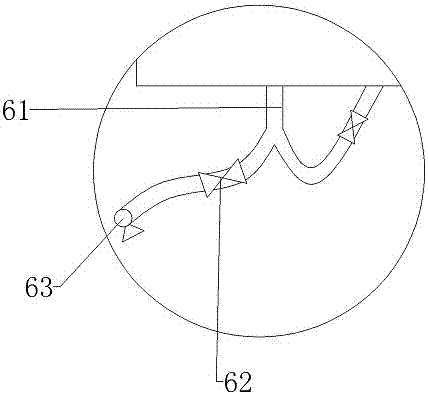

[0019] Reference numerals in the accompanying drawings include: frame 1, workbench 2, cutting knife 3, conveyor belt 4, shaping frame 5, air bag 6, inflation tube 61, control valve 62, air pump 63, magnet 7, electromagnet 8.

[0020] Such as figure 1 , figure 2 , image 3 Shown, the cutting device of automobile window glass comprises frame 1, and frame 1 comprises two vertical rods and the cross bar that is arranged on the top of two vertical rods, and cross rod is vertically slidably connected with vertical rod, and frame 1 A workbench 2 is arranged at the bottom, and a cutting knife 3 is slidably connected to the cross bar of the frame 1 .

[0021] Two conveyor belts 4 are arranged side by side on the workbench 2, and the two conveyor belts 4 are in contact. Shaping frame 5, the top of shaping frame 5 is lower than the top 3cm of conveyer belt 4, is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com