Dust removal device of printing machine

A technology of dust removal device and printing machine, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems of general dust removal effect and inconvenient installation of dust collection paper rolls, etc., achieve fast and efficient removal, improve dust removal effect, Avoid the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

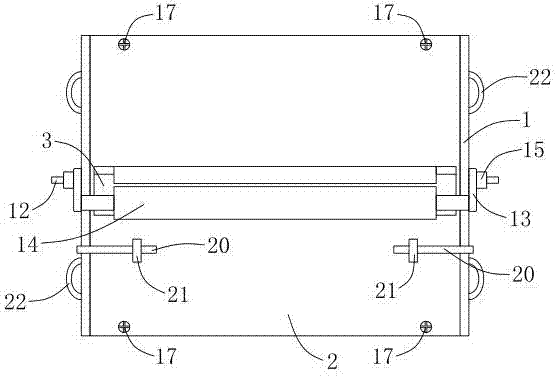

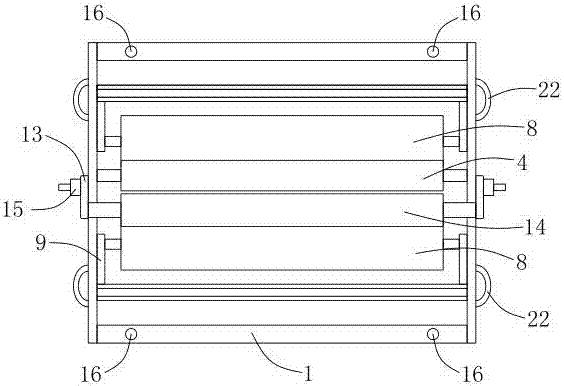

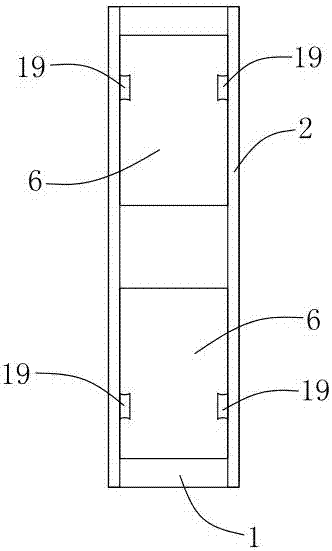

[0021] Such as Figure 1 to Figure 7 As shown, it is a dust removal device for a printing press according to the present invention, which includes a body 1, and a cover plate 2 is fixed on the body 1: a mounting hole 16 is provided on the body 1, and bolts 17 are arranged in the mounting hole 16 through the cover plate 2 to realize The cover plate 2 is fixedly connected to the body 1 . The cover plate 2 is provided with a discharge port 3, and the dedusted film coil is discharged from the discharge port 3. The body 1 is provided with dust removal rollers 4 , and the film coils 5 are driven between the dust removal rollers 4 , and the dust removal rollers 4 absorb the dust on the film coils 5 . There are two drawing holes 6 in the body 1, the drawing holes 6 are set up and down, and the installation base 7 is slidably connected to the drawing holes 6: the installation base 7 is provided with a chute 18, and the cover plate 2 is provided with The sliding protrusion 19 matches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com