Three-section double-motor stirring device applied to white carbon black production

A stirring device, a three-stage technology, applied in the field of a three-stage dual-motor stirring device, can solve the problems of low stirring efficiency of the stirring tank, uneven stirring of the slurry, and easy deposition of the slurry, so as to improve the random movement and improve the Stirring rate, the effect of solving the shaking of the tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

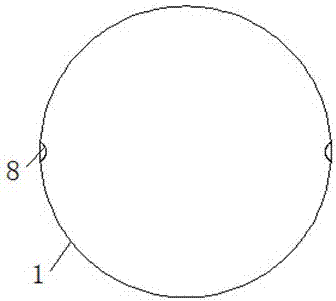

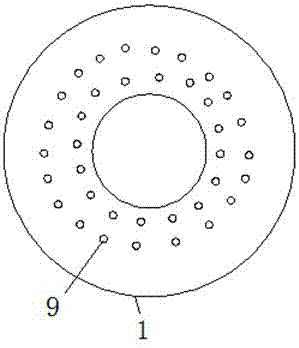

[0019] Such as figure 1 , figure 2 , image 3 As shown, the present invention is realized in this way, the upper and lower ends of the tank body 1 are correspondingly provided with a first drive motor 2 and a second drive motor 3, the first drive motor 2 is connected to the first stirring shaft 4, and the second drive motor 3 is connected to the first stirring shaft 4. Two stirring shafts 5, the first stirring shaft 4 and the second stirring shaft 5 are coaxially fixed at the center of the stirring tank body 1, the first stirring shaft 4 and the second stirring shaft 5 are respectively provided with three-stage stirring rods 6, and the first stirring shaft The length of the three-stage stirring rod 6 on the first stirring shaft 4 decreases successively from top to bottom, and the length of the three-stage stirring rod on the second stirring shaft increases successively from top to bottom. Two vertical smooth arc-shaped bumps 8 are vertically arranged, and the two vertical s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com