Food processor and machine head of food processor

A food processor and machine head technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of large motor load, low pulverization efficiency, poor pulverization effect, etc., and achieve the effect of reduced motor load and high pulverization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

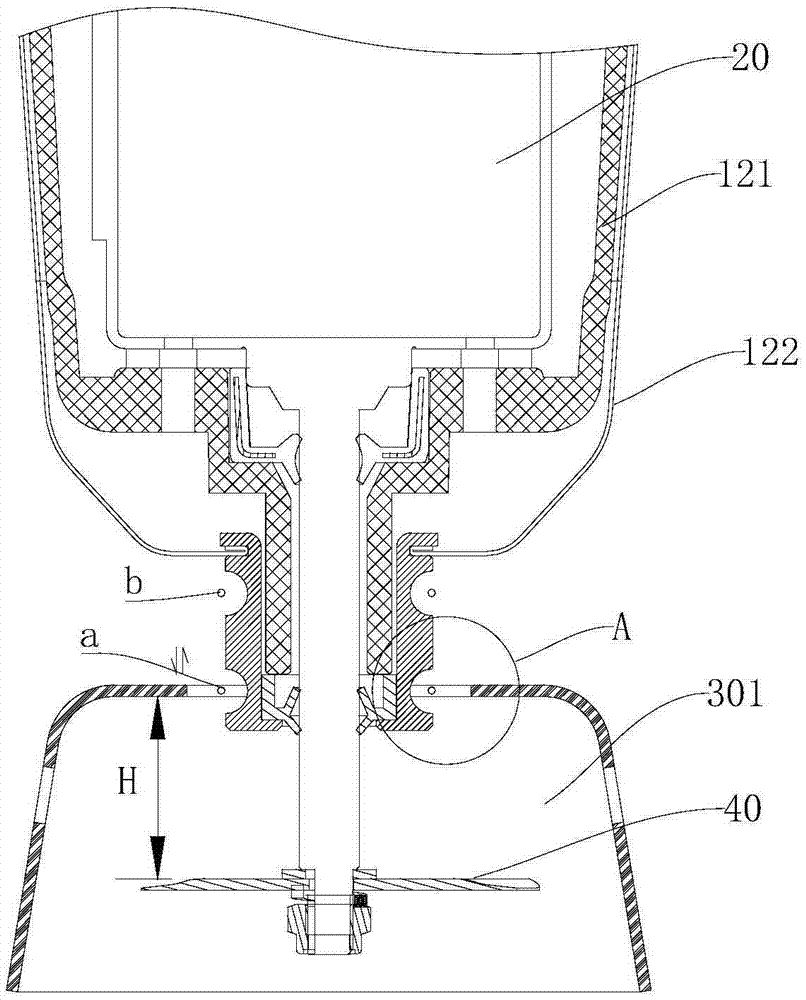

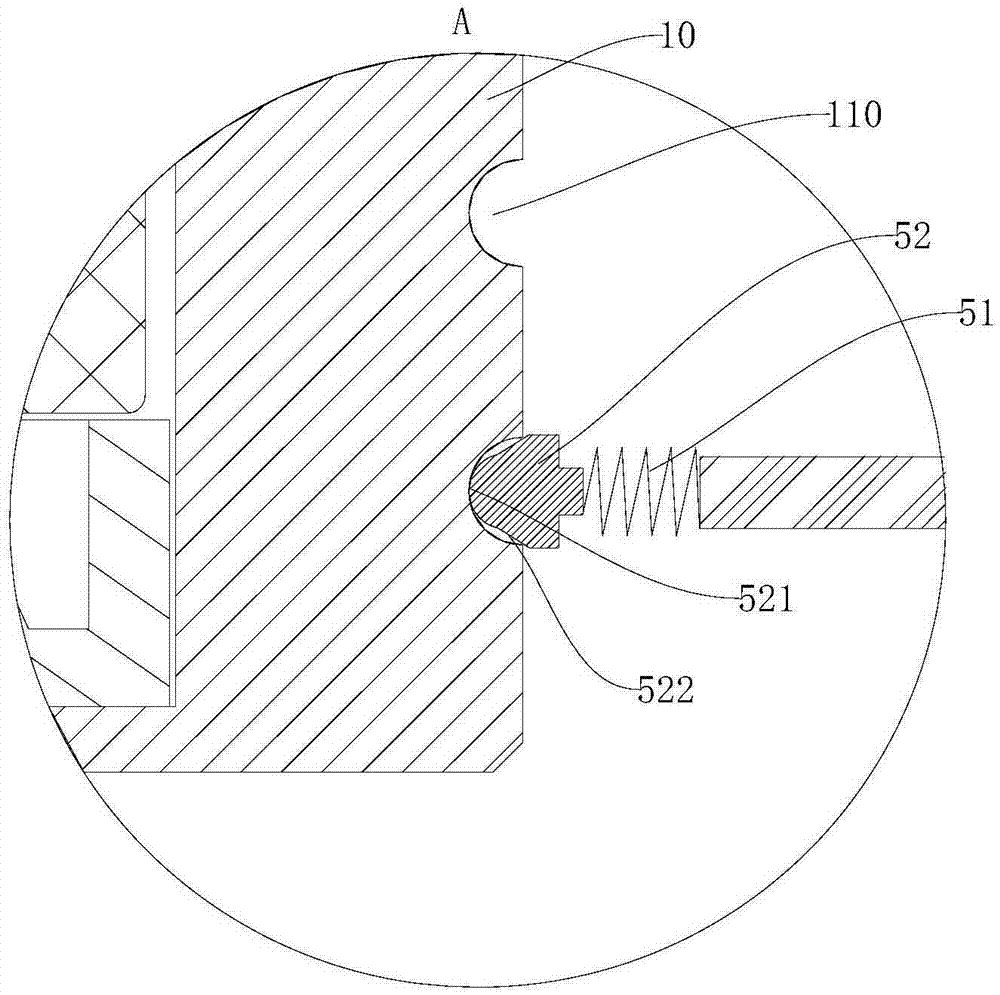

[0060] refer to Figure 1 to Figure 22 As shown, the head 100 of the food cooking machine according to the embodiment of the present invention may include: a head body 10 , a motor 20 , a grinder 30 and a pulverizer 40 . The motor 20 can be arranged in the machine head body 10, the grinder 30 can be connected with the machine head body 10 and can pivot around the axis of the machine head body 10, and the grinder 30 can move along the axial direction of the machine head body 10 relative to the machine head body 10. The position is adjustable, and the crushing member 40 can be set in the grinding cavity 301 of the grinder 30 and can rotate under the driving of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com