High-gain direct-current voltage converter capable of lowering current stress of switching tube

A DC voltage and current stress technology, which is applied in the direction of converting DC power input to DC power output, adjusting electrical variables, and output power conversion devices, can solve excessive capacitance stress, large current stress of switch tubes and diodes, and inductive current Large and other problems, to achieve the effect of reducing current stress and improving power capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

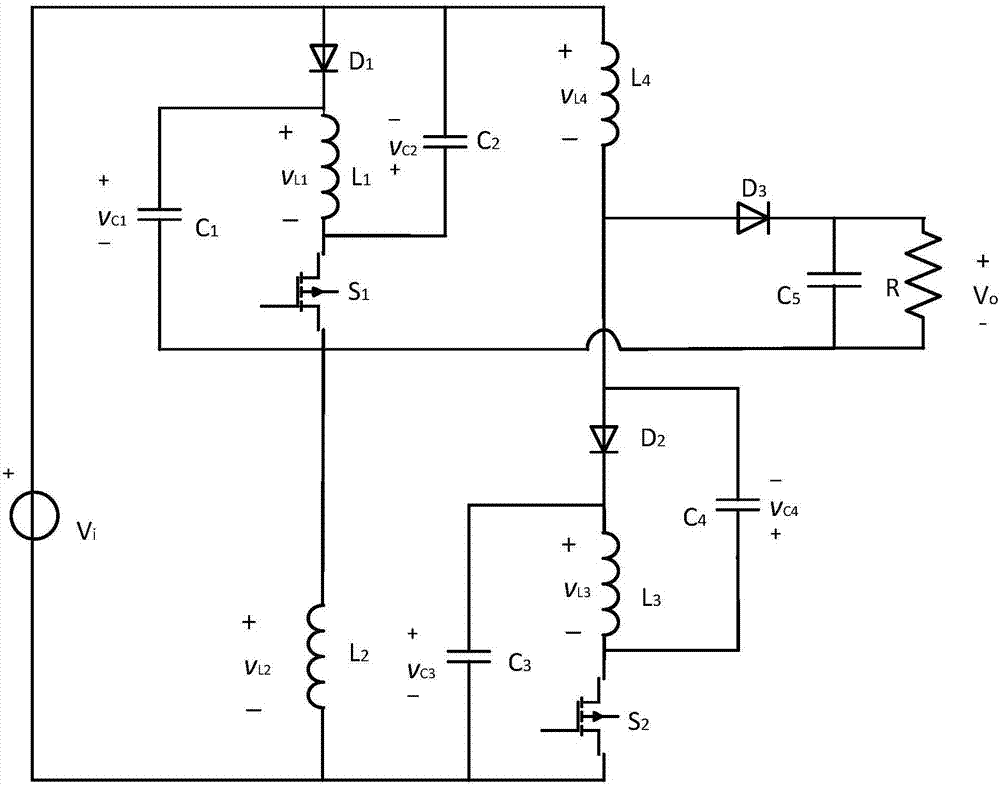

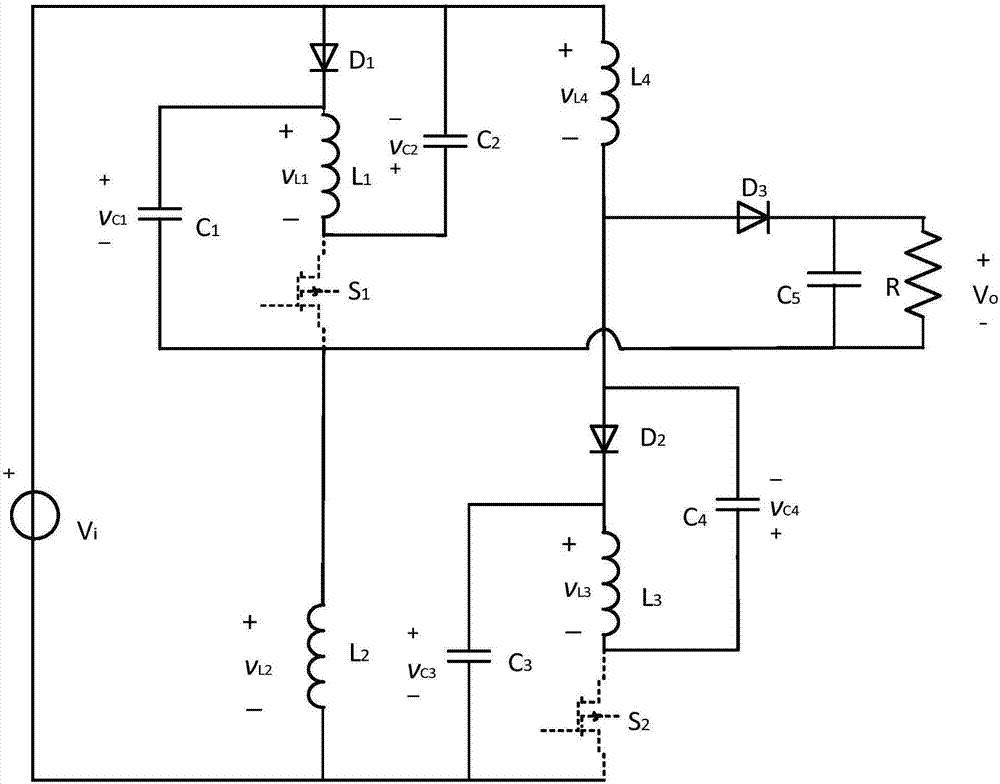

[0011] see figure 1 As shown, the high-gain DC voltage converter provided by this embodiment includes a voltage source V i , the first quasi-Z source module, the second quasi-Z source module, and the output module, the first quasi-Z source module is composed of the first capacitor C 1 , the second capacitance C 2 , the first inductance L 1 , the second inductance L 2 , the first switch tube S 1 and the first diode D 1 Composed of, the second quasi-Z source module consists of a third capacitor C 3 , the fourth capacitor C 4 , the third inductance L 3 , the fourth inductance L 4 , the second switch tube S 2 and the second diode D 2 Composed of, the output module consists of a third diode D 3 , the fifth capacitor C 5 and load R; the voltage source V i The anodes of the first diode D are respectively connected to the 1 The anode, the second capacitor C 2 The negat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com