Special aluminum section bar for shower room and production process for special aluminum section bar

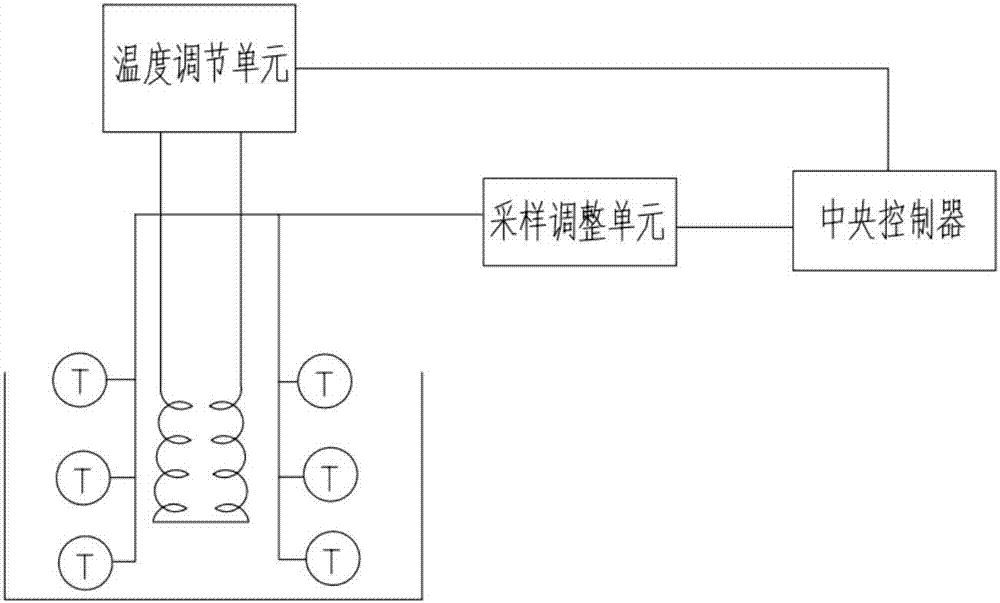

A production process and aluminum profile technology, applied in the direction of temperature control with electric mode, auxiliary controller with auxiliary heating device, etc., can solve the problems of insufficient chemical reaction, corrosion pits on the surface of aluminum alloy, and temperature control detection errors Large and other problems, to avoid the generation of yellow smoke, improve the environment, and improve the effect of large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The special aluminum profile for shower rooms of the present invention includes the following chemical components (parts by weight): 0.3-0.65% of silicon Si, 0.15% of iron Fe, 0.2-0.25% of copper Cu, 0.05% of manganese Mn, and magnesium Mg0. 70-0.95%, zinc Zn0.05%, titanium Ti0.05%, and the balance is aluminum Al.

[0015] The production process of the present invention is as follows: including the steps of melting and casting, extrusion, pretreatment, mechanical polishing, chemical polishing and hole sealing.

[0016] The extrusion process is a key to ensure the quality of the subsequent surface treatment. In the extrusion step of the present invention, the mold heating temperature is 450-520 degrees, the mold heating time is less than 8 hours, and the extrusion speed is 20-50m / min.

[0017] The pre-treatment includes degreasing and alkali etching steps. The purpose of degreasing is to remove oil stains and wet the surface, which is the key to ensure uniform alkali was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com