Novel ducted propeller device and achieving method thereof

A propeller and ducted technology, applied in the direction of propeller, power plant type, transportation and packaging, etc., can solve the problems of efficiency deterioration, large induced resistance, impact noise, etc., and achieve the goals of improving applicability, reducing diameter and reducing noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

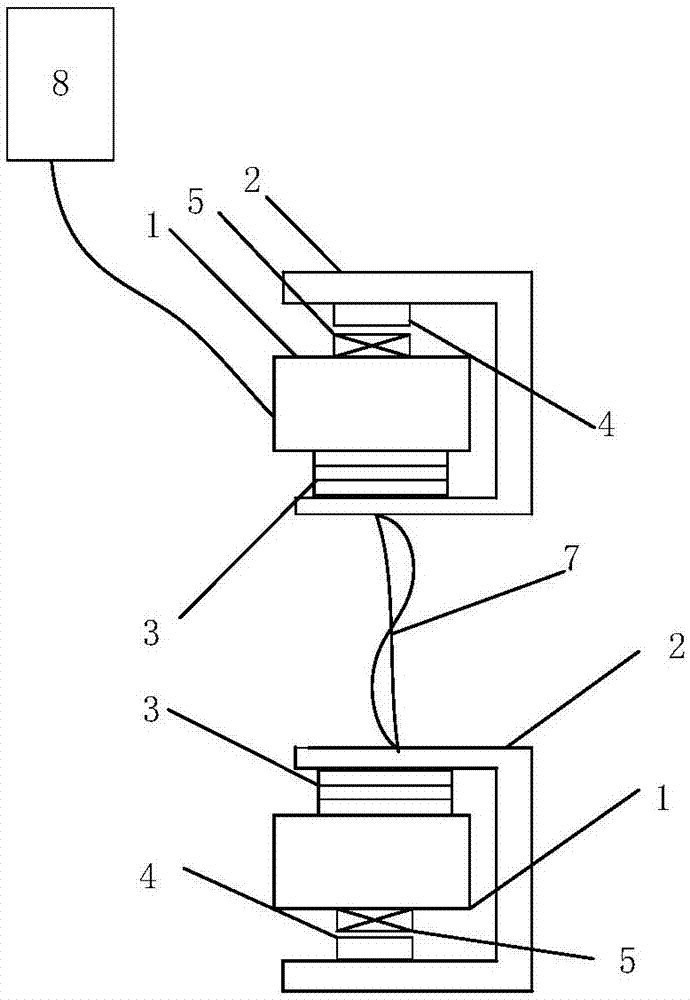

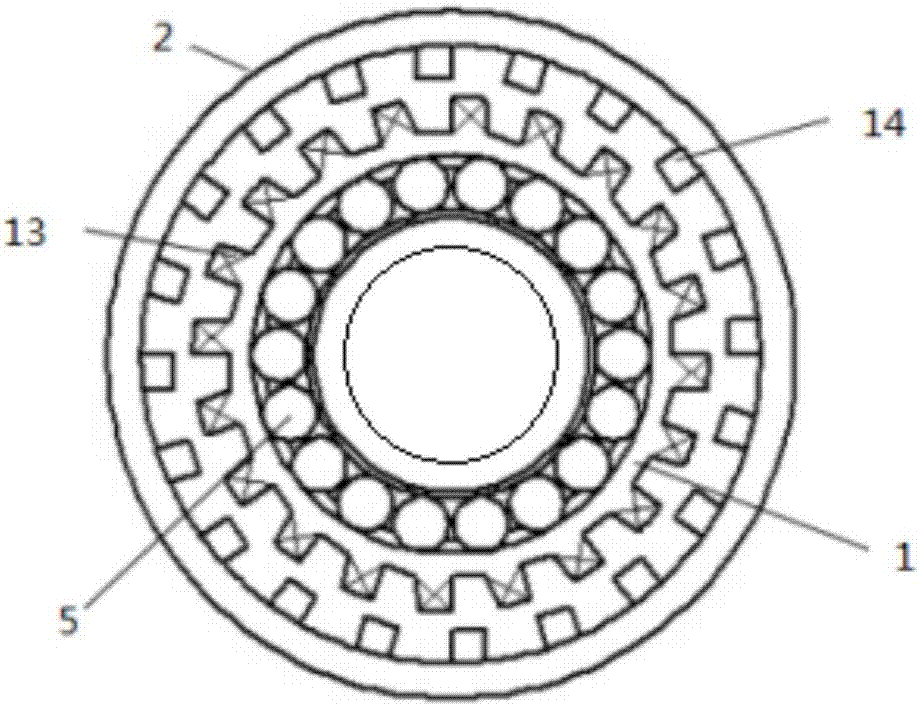

[0012] like figure 1 and figure 2 As shown in the figure, a novel ducted propeller device of the present invention includes a hollow cylindrical motor stator 1, a plurality of coils 5 are evenly wound on the outer wall of the motor stator 1, and the inner wall of the motor stator 1 is fixedly connected with the outer ring of the bearing 3 ; The motor rotor 2 is composed of two mutually nested cylindrical structures and a ring structure, and the two mutually nested cylindrical structures are connected together by the ring structure at the end of the cylindrical structure, and the cylindrical structure inside the motor rotor 2 The cylindrical structure passes through the center of the bearing 3 and is fixedly connected with the inner ring of the bearing 3. The cylindrical structure outside the motor rotor 2 is sleeved on the outside of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com