Protection layer, electronic device and manufacturing method of electronic device

A technology of electronic equipment and protective layer, which is applied in the electronic field, can solve the problems of scratch resistance and brittle fracture, and achieve the effects of improving fixation, abrasion resistance and flexibility, and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

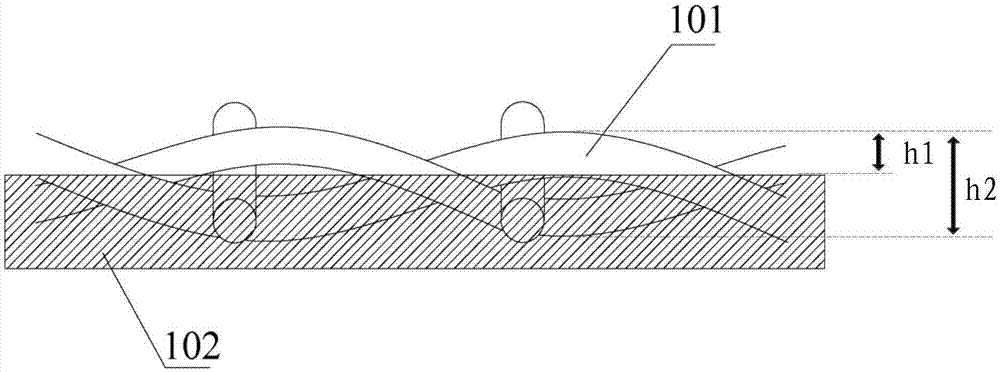

[0049] Please refer to figure 1, Embodiment 1 of the present application provides a protective layer for a display screen, including:

[0050] The fiber layer 101 is laid flat in the elastic matrix, and the fiber layer is made of a material with a predetermined degree of flexibility and a predetermined degree of wear resistance;

[0051] The elastic matrix 102 has a preset degree of elasticity, and the adhesive force between the elastic matrix and the fiber layer and the adhesive force between the elastic matrix and the display screen surface are greater than or equal to the preset adhesive force;

[0052] Wherein, the transparency of the protective layer is greater than or equal to a preset transparency.

[0053] The fiber layer can be made of materials with high flexibility and high wear resistance, such as modified polyurethane fibers, glass fibers, alumina fibers and the like. Of course, in order not to affect the light transmittance of the protective layer, the fiber la...

Embodiment 2

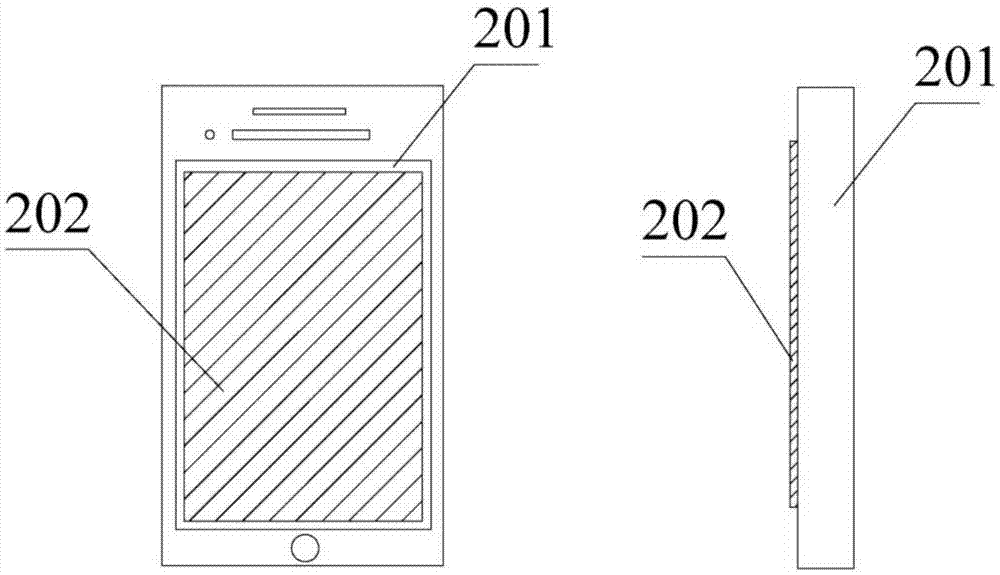

[0080] Please refer to figure 2 , Embodiment 2 of the present application provides an electronic device, including:

[0081] display screen 201;

[0082] As for the protective layer 202 in the first embodiment, the protective layer 202 is attached to the screen surface of the display screen.

[0083] Optionally, the fiber layer includes a plurality of fibers that are parallel to each other and at uniform intervals. When the display screen is bent and deformed, the folding marks generated by the display screen are parallel to the plurality of fibers, and the protection The layers are simultaneously deformed by bending so that the fiber layer is always parallel to the screen surface.

[0084] aforementioned figure 1 Various changes and specific examples of the protective layer in the embodiment are also applicable to the electronic device in this embodiment. Through the foregoing detailed description of the protective layer, those skilled in the art can clearly know that the...

Embodiment 3

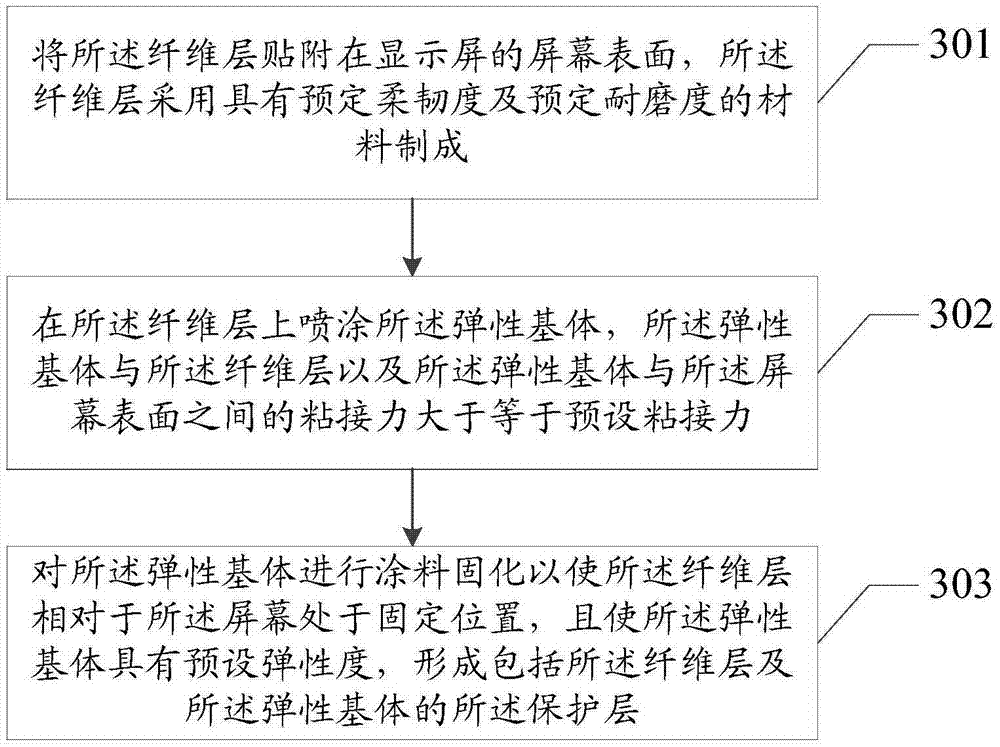

[0086] Please refer to image 3 Embodiment 3 of the present application provides a method for manufacturing an electronic device as described in Embodiment 2, including:

[0087]Step 301: Attach the fiber layer on the screen surface of the display screen, the fiber layer is made of a material with a predetermined degree of flexibility and a predetermined degree of wear resistance.

[0088] Step 302: Spraying the elastic matrix on the fiber layer, the adhesive force between the elastic matrix and the fiber layer and between the elastic matrix and the screen surface is greater than or equal to a preset adhesive force.

[0089] Step 303: Curing the coating on the elastic matrix so that the fiber layer is in a fixed position relative to the screen, and the elastic matrix has a predetermined degree of elasticity, forming a composite material including the fiber layer and the elastic matrix The protective layer, wherein the transparency of the protective layer is greater than or eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com