Shielding connecting structure

A technology of shielding structure and connector, applied in the direction of connection, two-part connection device, protective grounding/shielding device of connection parts, etc., can solve the problems of inconvenient assembly, high labor cost, high parts cost and assembly cost, etc. Convenience, simple process and waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

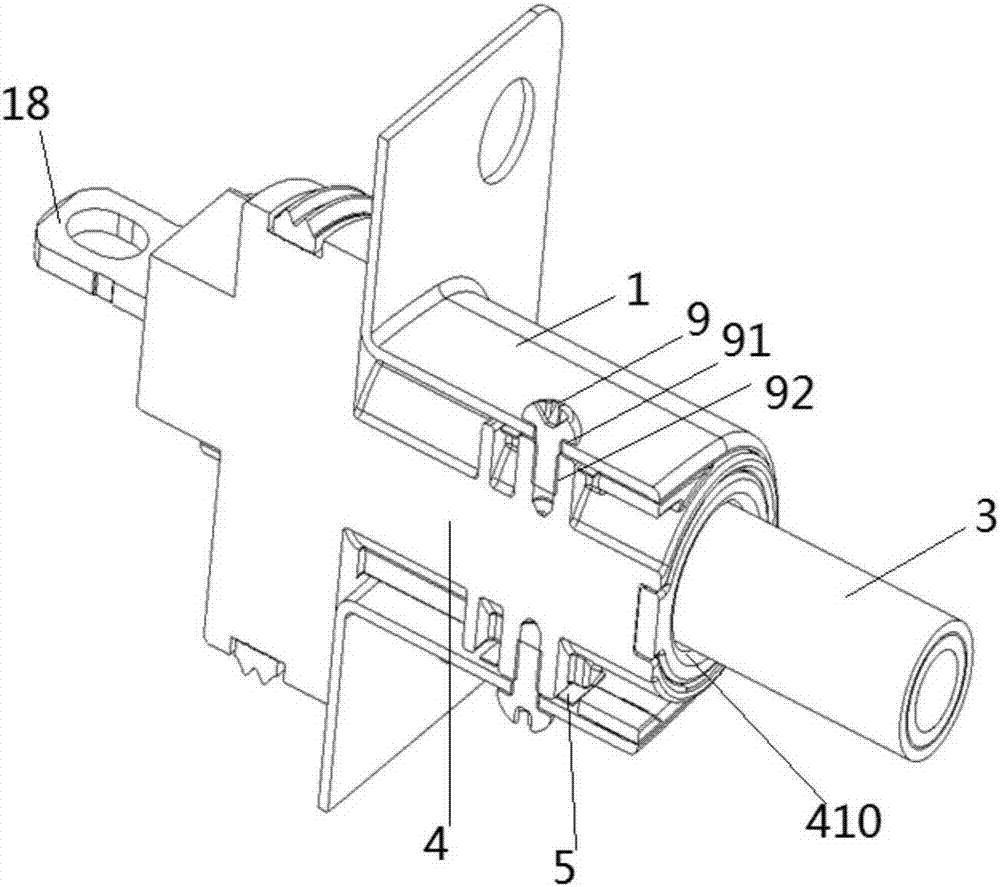

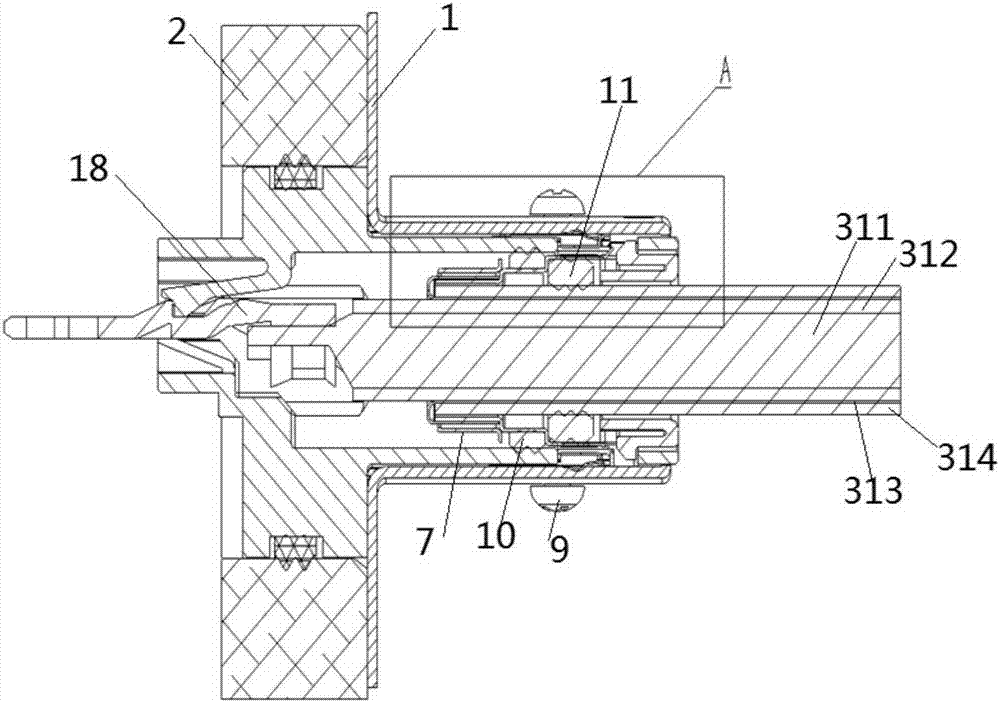

[0088] In the following, reference will be made to Figures 1 to 12 A shield connection structure according to an embodiment of the present invention will be described.

[0089] The shielding connection structure of the present invention is suitable for connecting shielded wires to connectors and realizing shielding conduction, and is also suitable for connecting unshielded wires to connectors and realizing shielding conduction. In this embodiment, the connector refers to a high-voltage connector for high voltage, which will be connected to the electrical housing, and of course it is also applicable to other types of connectors.

[0090] First, by referring to figure 1 -7 describes the condition of the shielding structure when shielding the wire.

[0091] like Figure 5 As shown, the shielded electric wire 3 in this embodiment is a coaxial cable, including: a conductor 311, for example, made by twisting a plurality of strands, or a single strand; an insulating layer made o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com