Injection type microsphere inflation system

An inflatable system and inflatable chamber technology, applied in the direction of climate sustainability, reduction of greenhouse gases, nuclear reactors, etc., can solve problems such as unsuitable, ineffective and difficult to inflate, and achieve high inflatable success rate, small glue spots, and difficult to inflate cracked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

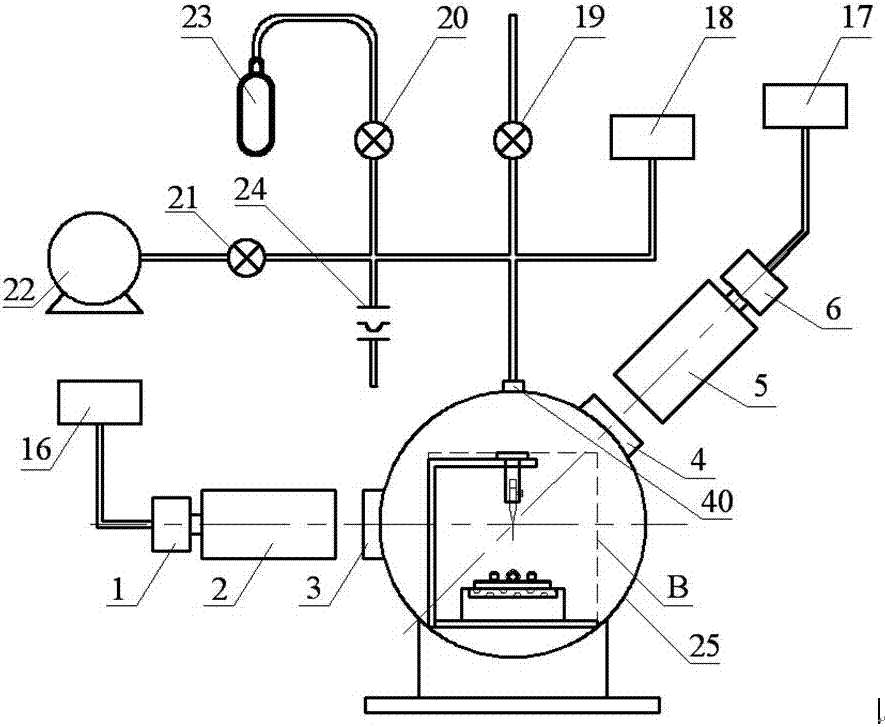

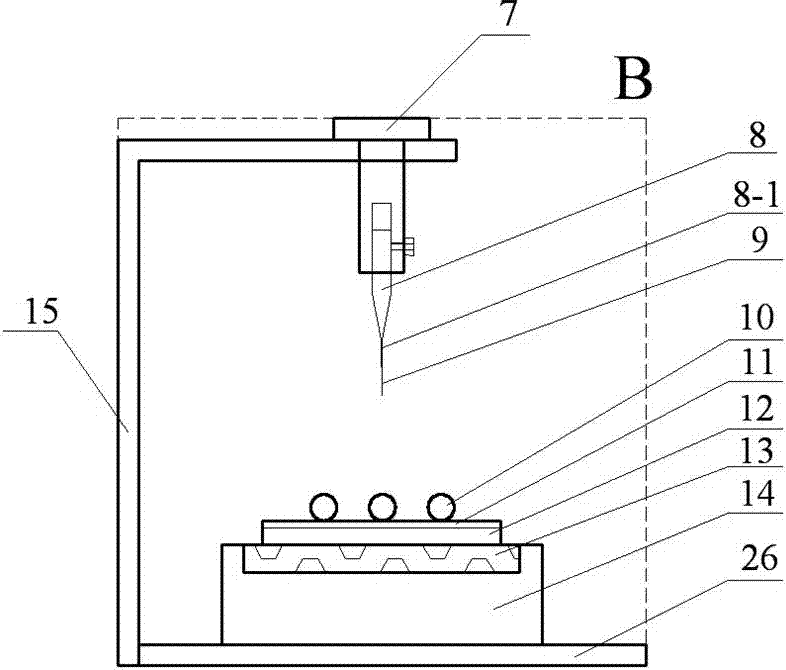

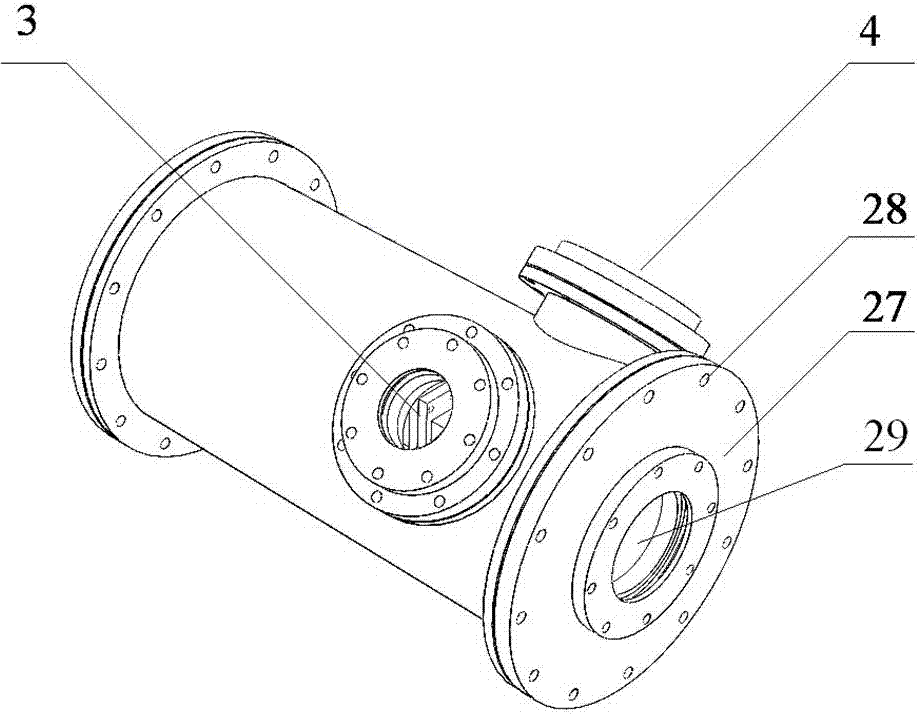

[0023] figure 1 It is a schematic diagram of the overall layout of the injection-type microsphere inflation system of the present invention; figure 2 for figure 1 The partial enlarged view of the three-view mirror high-pressure inflatable chamber in , specifically figure 1 Schematic diagram of the structure in frame B; image 3 It is a schematic diagram of the appearance structure of the three-view mirror high-pressure inflatable chamber in the present invention; Figure 4 It is a schematic structural view of the three-view mirror high-pressure inflatable chamber in the present invention; Figure 5 for Figure 4 Partial enlarged view in , specifically Figure 4 Schematic diagram of the structure in box A. exist Figure 1-Figure 5Among them, an injection-type microsphere inflation system of the present invention includes a three-view mirror high-pressure inflation chamber 25, a dispensing system, a long working distance imaging system, a vacuum and an inflation system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com