A microsphere semi-automatic dispensing and sealing device and method

A sealing device, semi-automatic technology, applied in the container filling method, the device for coating liquid on the surface, packaging, etc., can solve the problems of the undisclosed microsphere inflation method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

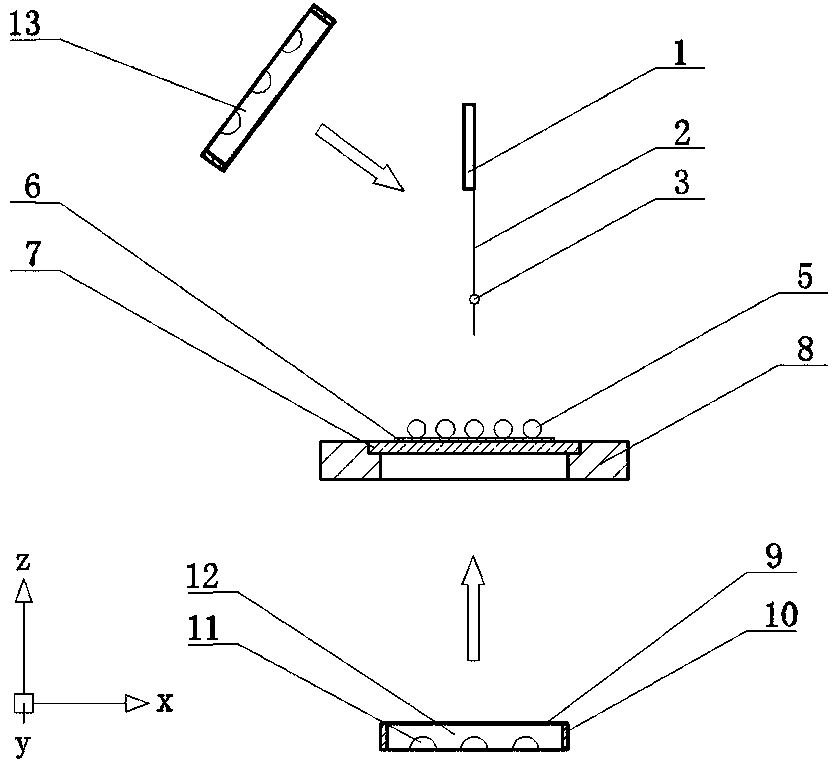

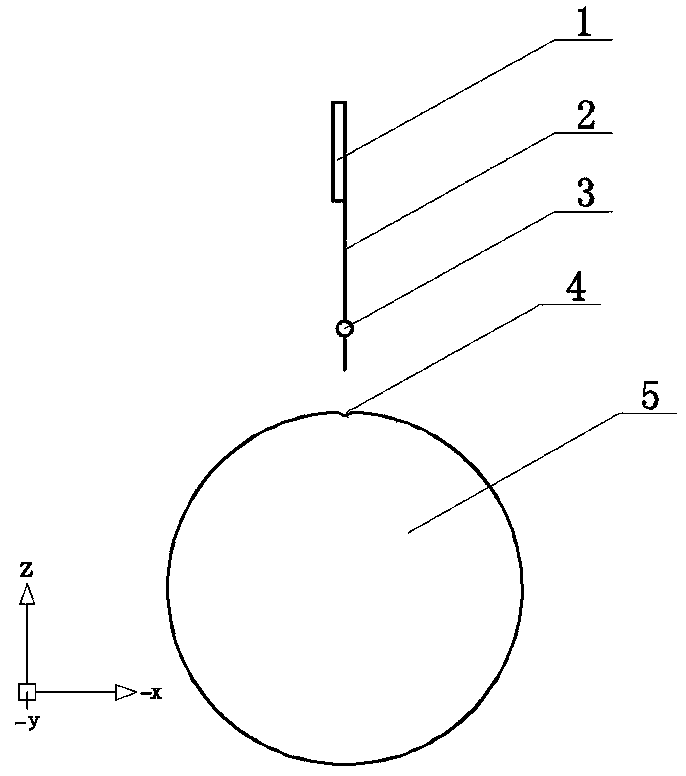

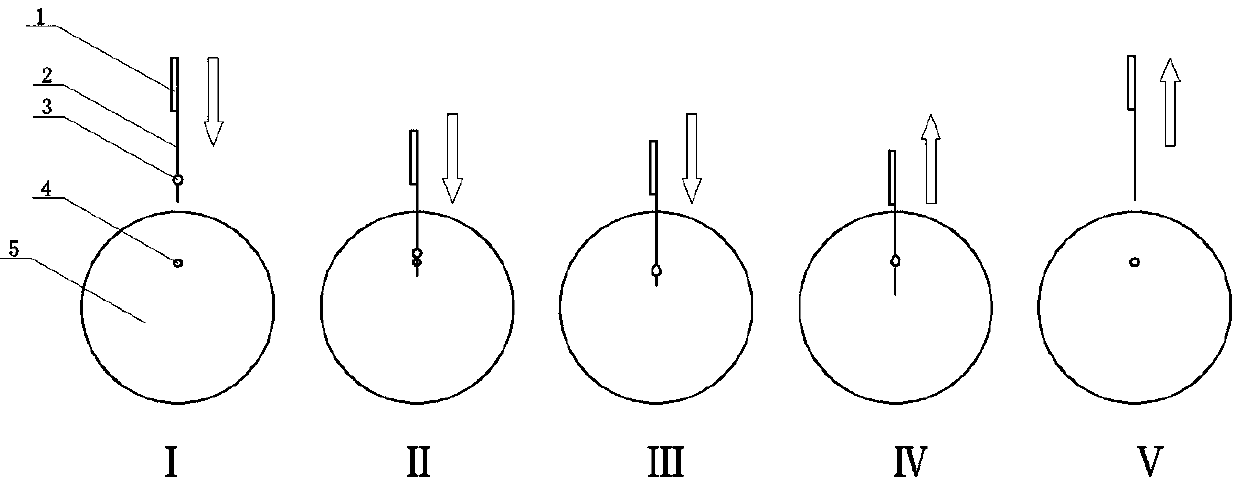

[0047] exist Figure 1~Figure 4 Among them, a microsphere semi-automatic dispensing and sealing device of the present invention includes a three-view mirror high-pressure air chamber, a precise positioning three-dimensional mobile sample stage, a dispensing system, and a long working distance imaging system;

[0048] The high-pressure inflatable chamber of the three-view mirror adopts a cylindrical structure, and the center axis of the circle is placed in the horizontal direction. The front and rear of the high-pressure inflatable chamber of the three-view mirror are equipped with circular sealing covers, and the left side is axially provided with a horizontal Direction window, the right side is rotated 45 degrees counterclockwise along the horizontal axis to set a 45-degree direction window; the observation port of the left window facing the high-pressure inflatable chamber of the three-view mirror is equipped with a horizontal long working distance microscope, which is connec...

Embodiment 2

[0076] In this embodiment, the PMAS gold-coated microspheres are used to fill with argon

[0077] The implementation process of this embodiment is the same as the method of embodiment 1, the difference is that in this embodiment, the dispensing wire 2 in steps b, c, d, f, g uses tungsten wire; steps a, d, g The diameter of micropore 4 in is 20 μ m;

[0078] In this example, due to the poor light transmittance of the metal microspheres, the micropores cannot be observed by using the bottom light. In the implementation process (d) in the pre-adjustment of the micropores of the inflated microsphere samples, only the side top light source can be used. Adjust the irradiation angle and control the brightness, and need to increase the hole diameter to 20μm to observe the microholes more clearly and complete the glue sealing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com