Method for predicting the lifting of two-phase flow screw pump of shallow-layer heavy oil reservoir

A heavy oil reservoir and screw pump technology is applied in the prediction field of lifting of two-phase flow screw pump in shallow heavy oil reservoir, which can solve the problems of increased workload, limitation of applicable conditions, economic loss per oil field, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Taking a certain well in a block of Xinjiang Oilfield as an example to judge the crude oil lifting capacity of the screw pump,

[0046] S100, the depth of the oil reservoir in this well area is 1700m, within the lifting range of the conventional screw pump, the screw pump is used for production, and the water cut of the oil well is 0%;

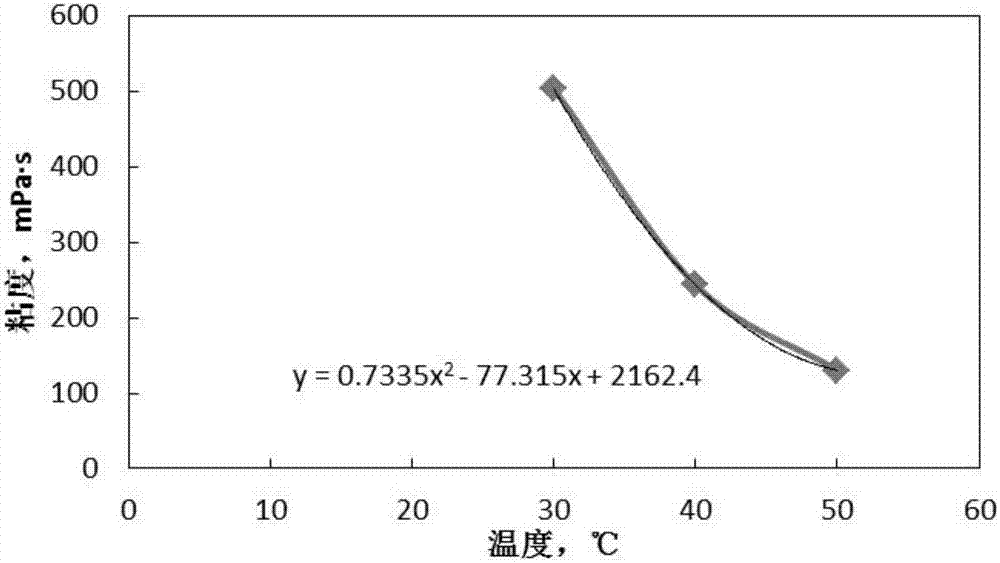

[0047] S200, determine the relevant parameters of the reservoir oil well for production and development (as shown in Table 2), and measure the viscosity-temperature relationship and geothermal gradient on the spot;

[0048] Table 2

[0049]

[0050] S300, daily output 3m 3 / d can determine that the lifting speed is 0.0176m / s, and the reservoir depth can determine that the head of the screw pump is 17MPA;

[0051] S400. Calculate the oil well in sections, and calculate the crude oil viscosity according to the relationship between the reservoir depth and the crude oil viscosity, make a section every 100m, make an average value of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com