Electrorheological fluid shock absorber and control method, control unit and ECU thereof and automobile

A technology of electrorheological fluid and control unit, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., and can solve problems such as unstable operation of shock absorbers, easy foaming, and affecting the performance of electrorheological fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

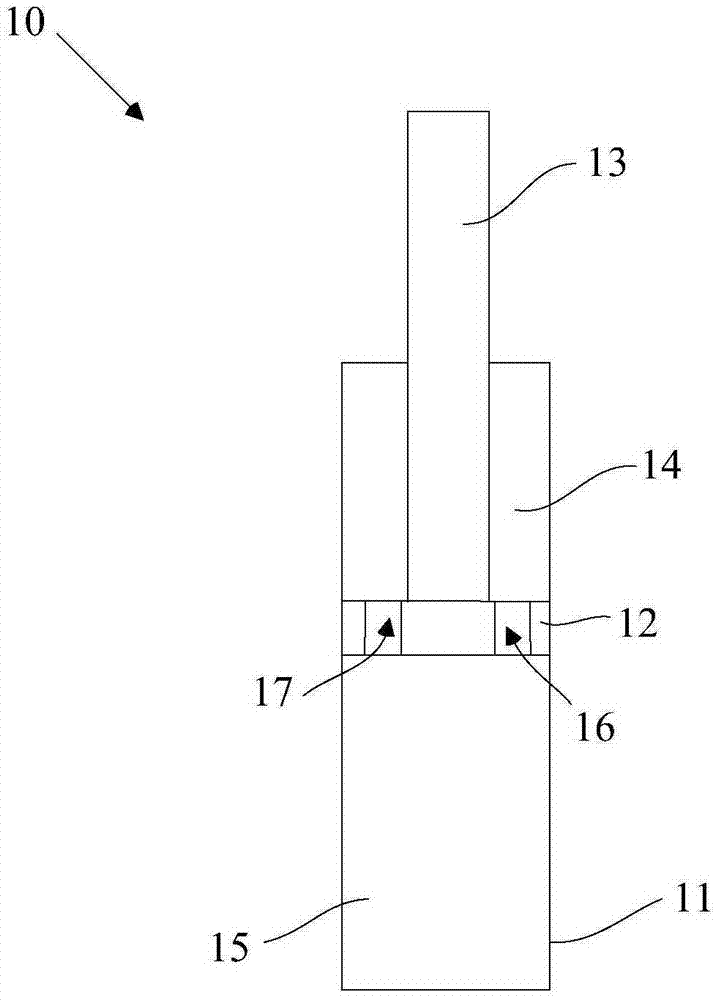

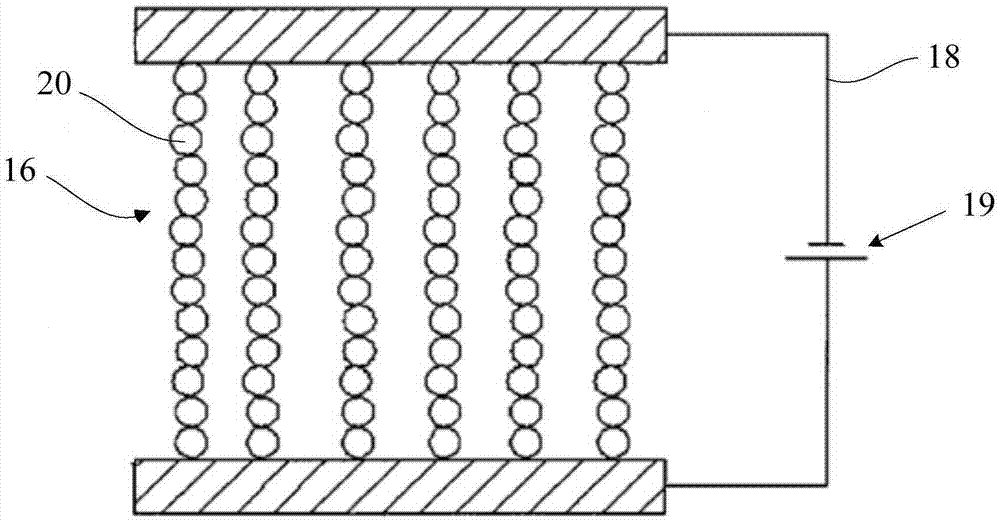

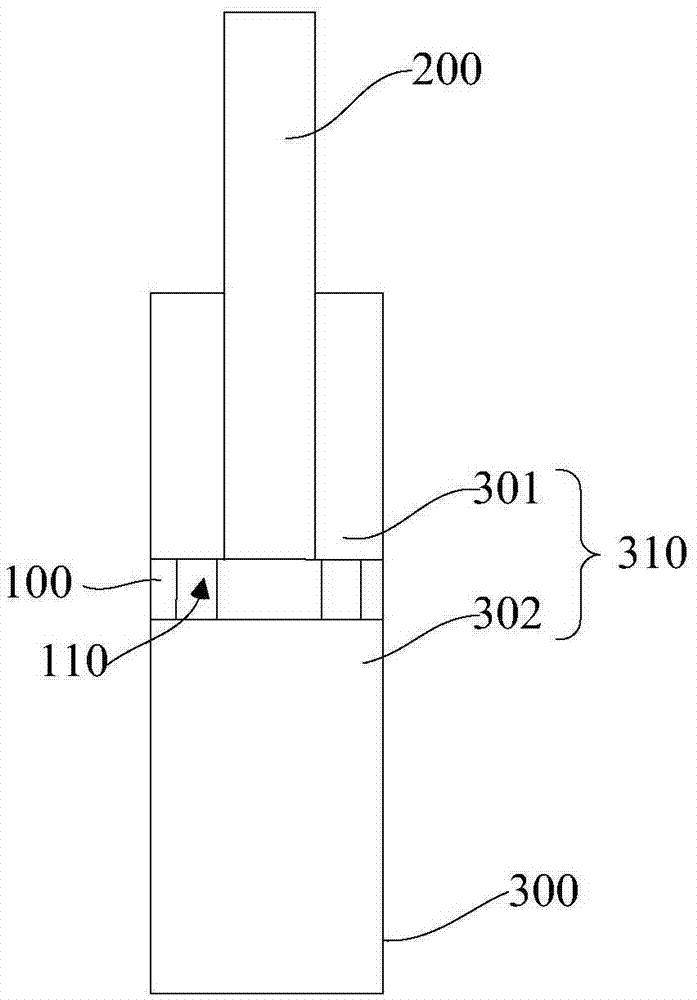

[0121] refer to image 3 and combine Figure 4 As shown, the embodiment of the present invention provides an electrorheological fluid shock absorber, including: a piston 100, and a piston rod 200 arranged on the piston 100, the piston rod 200 is installed on the piston 100 through a lock nut 101; a working chamber 310 , the piston 100 is located in the working chamber 310. In this embodiment, the working chamber 310 is sleeved on the outer peripheral surface of the piston 100; a piston rubber 102 is provided between the outer peripheral surface of the piston 100 and the working chamber 310, and the piston rubber 102 adopts Adding a high-performance filler modified filled polytetrafluoroethylene material can make the outer peripheral surface of the piston 100 and the inner peripheral surface of the working chamber 310 tightly sealed. At the same time, when the piston 100 moves axially in the working chamber 310, the piston wraps The rubber 102 is wear-resistant, and the fricti...

Embodiment 2

[0127] In this embodiment, the structure of the working chamber 310 is the same as that of the working chamber 310 in Embodiment 1, the difference is that, refer to Figure 4 , also includes: a closed first annular chamber 601 surrounding the upper and lower working chambers; a ring member 602 is arranged in the first annular chamber 601, and the ring member 602 divides the first annular chamber 601 into an upper chamber 601a and a lower chamber 601b, the ring 602 can move under the pressure difference between the upper working chamber 301 and the lower working chamber 302; the upper chamber 601a is filled with giant electrorheological fluid, and the lower chamber 601b is filled with compressed air; the compressed air is an inert gas , such as nitrogen, the air pressure is 1Mpa-1.2Mpa, including 1Mpa and 1.2Mpa; the ring 602 can be a ring with a certain thickness, and the ring 602 is closely attached to the inner peripheral surface of the ring cavity 601; the upper cavity 601a ...

Embodiment 3

[0140] In this embodiment, the structure of the working chamber 310 is the same as that of the working chamber 310 in Embodiment 1, the difference is that, refer to Figure 9 , in this embodiment, it also includes: a closed second annular chamber 701 surrounding the upper and lower working chambers; the second annular chamber 701 communicates with the upper working chamber 301 and the lower working chamber 302 respectively, and the second annular chamber 701 serves as a damping channel .

[0141] Also includes: a valve cover 400, the top wall of the upper working chamber 301 and the second annular cavity 701 is served by the valve cover 400; the valve cover 400 has an annular gap 401 around the piston rod 200, and the annular gap 401 communicates with the second annular cavity 701 and The upper working chamber 301 ; or, the side wall of the second annular chamber 701 has a hole, and the hole communicates the second annular chamber 701 with the upper working chamber 301 .

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Damping force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com