A kind of manufacture method of laver extract fiber

A manufacturing method and extract technology, applied in the field of laver extract fiber, can solve the problems of complex laver extraction process, poor spinning effect of products, limited purity, etc., shorten digestion time, reduce production energy consumption and operability, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

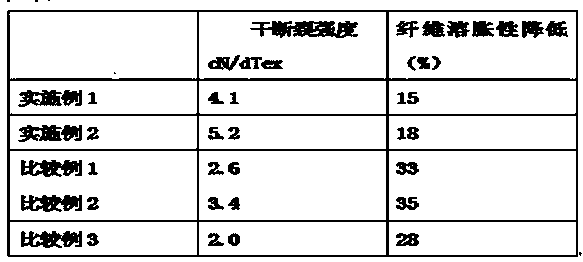

Examples

Embodiment 1

[0024] Step A: Laver Extract Extraction

[0025] (1) Soak the selected seaweed in acetic acid solution, remove the seaweed and drain the water, and then steam it at 100°C, steam it away from the water for 8 minutes, take it out for later use, and dry the steamed seaweed until Moisture≤11-13%

[0026] (2) Carry out steam explosion treatment to the pretreated laver under pressure of 1.4MPa for 2.3min;

[0027] (3) Enzyme treatment: Then add low-temperature cellulase to the product obtained in step (2), and enzymolyze it in a water bath at 35°C for 24 hours,

[0028] (4) Add water 11 times (m / V, g / ml) relative to the dry weight of laver after enzymification, and use a tube centrifuge to centrifuge at a speed of 15000r / min to achieve laver digested residue and supernatant liquid separation;

[0029] (5) The laver digested residue after centrifugation is mainly laver fiber, which is bleached with 0.5% hydrogen peroxide that is 15 times (m / V, g / ml) relative to the dry weight of t...

Embodiment 2

[0035] Step A: Laver Extract Extraction

[0036] (1) Soak the selected seaweed in the acetic acid solution, remove the seaweed and drain the water, and then steam it at a temperature of 90°C, steam it away from the water for 7 minutes, take it out for later use, and dry the steamed seaweed until Moisture≤12%

[0037] (2) Carry out steam explosion treatment to the laver after pretreatment under 1.3MPa pressure maintenance pressure 2.3min;

[0038] (3) Enzyme treatment: then add low-temperature cellulase to the product obtained in step (2), and enzymolyze it in a water bath at 25°C for 48 hours,

[0039] (4) Add water 5 times (m / V, g / ml) relative to the dry weight of laver after enzymification, and use a tube centrifuge to centrifuge at a speed of 2000r / min to achieve laver digested residue and supernatant liquid separation;

[0040] (5) The laver digested residue after centrifugation is mainly laver fiber, which is bleached with 0.52% hydrogen peroxide that is 20 times (m / V, g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com