Standard oil replacing IRM902 and used for rubber oil-resistant detection and preparation method of standard oil

A technology of standard oil and rubber oil, which is applied in the direction of measuring devices, material inspection products, instruments, etc., can solve the problems of high price and increased cost, and achieve the effects of enhancing anti-oxidation performance, improving viscosity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

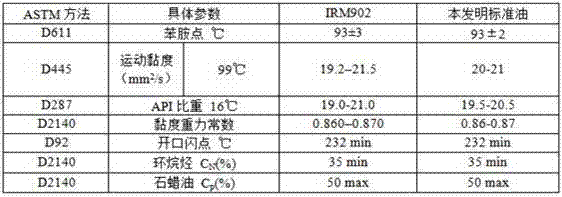

Method used

Image

Examples

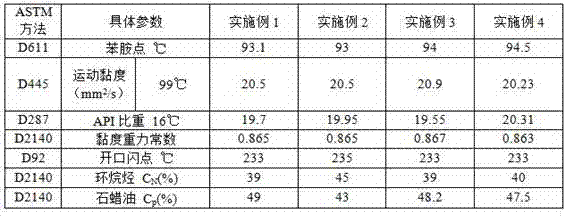

Embodiment 1

[0017] The rubber liquid of the present invention affects the experiment with the component weight ratio of standard oil as follows:

[0018] Diisoamylnaphthalene 11.7kg, KN4010 naphthenic rubber oil 24kg, KN4006 naphthenic rubber oil 44kg, KG-12 rubber oil 8kg, KG-06 rubber oil 12kg, antioxidant T501 0.3kg.

[0019] Mix the above diisoamylnaphthalene, KN4010 naphthenic rubber oil, KN4006 naphthenic rubber oil, KG-12 rubber oil, KG-06 rubber oil, and antioxidant T501 evenly.

Embodiment 2

[0021] The rubber liquid of the present invention affects the experiment with the component weight ratio of standard oil as follows:

[0022] Diisoamyl naphthalene 12kg, KN4010 naphthenic rubber oil 26.2kg, KN4006 naphthenic rubber oil 43kg, KG-12 rubber oil 6.6kg, KG-06 rubber oil 11.3kg, antioxidant T501 0.3kg, polyisobutylene 0.6 kg.

[0023] Mix the above diisoamylnaphthalene, KN4010 naphthenic rubber oil, KN4006 naphthenic rubber oil, KG-12 rubber oil, KG-06 rubber oil, antioxidant T501, and polyisobutylene evenly.

Embodiment 3

[0025] Rubber liquid of the present invention influences experiment to use standard oil configuration process as follows:

[0026] Get 12.2kg of diisoamylnaphthalene, 27.5kg of KN4010 naphthenic rubber oil, 41.4kg of KN4006 naphthenic rubber oil, 7kg of KG-12 rubber oil, 11kg of KG-06 rubber oil, and 0.3kg of antioxidant T501 and mix evenly. After testing its viscosity is 19.63, add 0.6kg of polyisobutylene, and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com