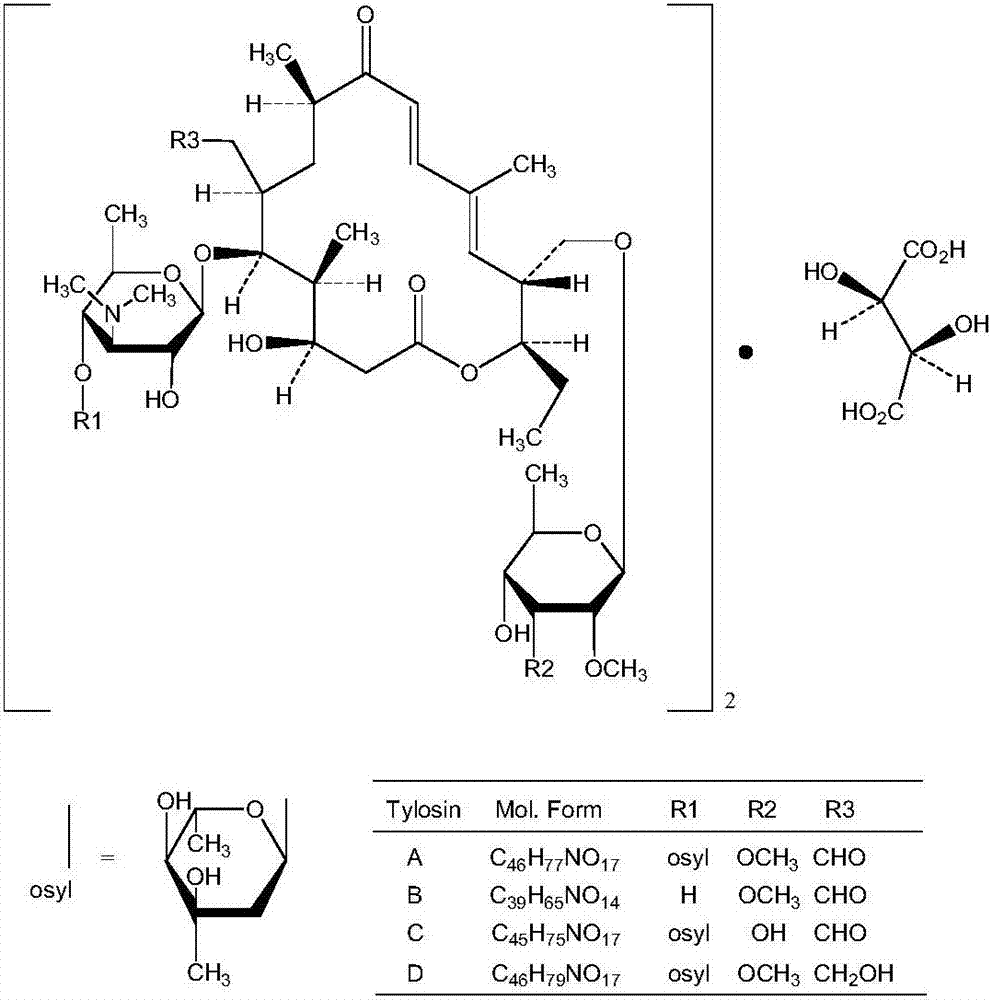

Method for using tylosin D as raw material to prepare tilmicosin

A technology of tilmicosin and tylosin, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of high residual impurities and low yield, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

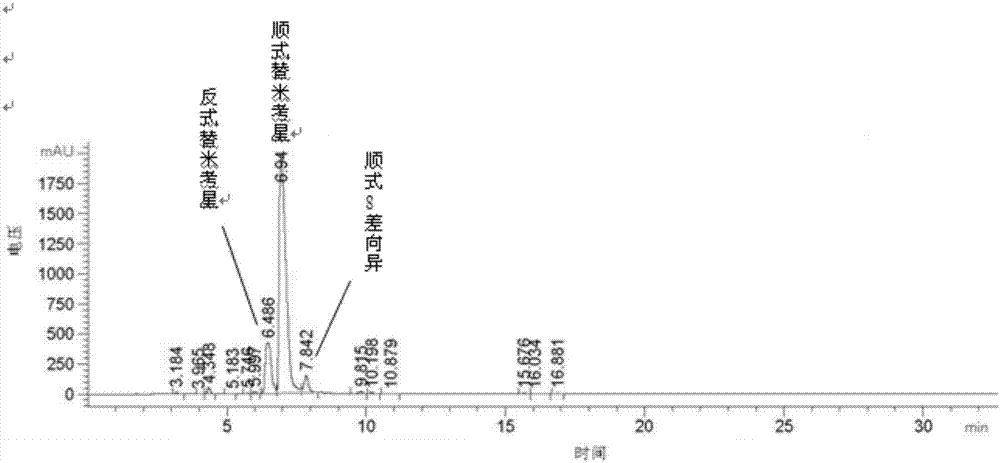

Examples

Embodiment 1

[0049]A method for preparing tilmicosin using tylosin D as a raw material, the steps are as follows:

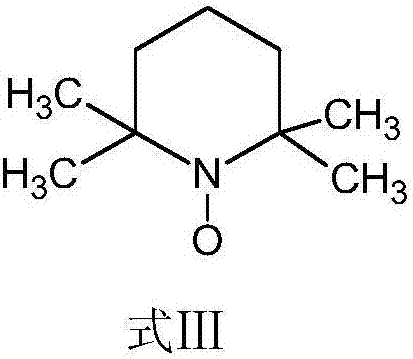

[0050] (1) Add 91.8g of tylosin D into 500g of ethyl acetate, keep the temperature at 0-5°C, add 1.2gKBr, 0.8gTEMPO, 8.4g of sodium bicarbonate, stir well, slowly add dropwise 373g of 10% NaClO solution, and react After 4 hours, after the reaction was completed, the layers were separated, the water phase was discarded, and the organic phase was intermediate 1 ethyl acetate solution.

[0051] (2) Add 500g of purified water to the solution of intermediate 1 obtained in step (1), add 8.3g of hydrochloric acid, static layer, remove the organic phase, raise the temperature of the water phase to 50°C for reaction, and hydrolyze for 1.0h to obtain the intermediate 2;

[0052] (3) Add the aqueous solution of intermediate 2 obtained in step (2) to ethyl acetate, adjust the pH value to 8.0 with sodium hydroxide solution, separate the layers at rest, discard the water phase, and add 3,...

Embodiment 2

[0054] A method for preparing tilmicosin using tylosin D as a raw material, the steps are as follows:

[0055] (1) Add 91.8g of Tylosin D to 1000g of ethyl acetate, keep the temperature at 0-5°C, add 1.8gKBr, 1.2gTEMPO, 12.6g of sodium bicarbonate, stir evenly, slowly drop 560g of 10% NaClO solution, and react After 5 h, after the reaction was completed, the layers were separated, the water phase was discarded, and the organic phase was intermediate 1 ethyl acetate solution.

[0056] (2) Add 500g of purified water to the solution of intermediate 1 obtained in step (1), add 16.6g of hydrochloric acid, static layer, remove the organic phase, raise the temperature of the water phase to 50°C for reaction, and hydrolyze for 0.5h to obtain the intermediate 2;

[0057] (3) Add the aqueous solution of intermediate 2 obtained in step (2) to ethyl acetate, adjust the pH value to 10.0 with sodium hydroxide solution, separate the layers at rest, discard the water phase, and add 3,5-dimet...

Embodiment 3

[0059] A method for preparing tilmicosin using tylosin D as a raw material, the steps are as follows:

[0060] (1) Add 91.8g of tylosin D to 1500g of ethyl acetate, keep the temperature at 0-5°C, add 2.4gKBr, 1.8gTEMPO, 19.0g of sodium bicarbonate, stir evenly, slowly drop 746g of 10% NaClO solution, and react After 6h, after the reaction was completed, the layers were separated, the water phase was discarded, and the organic phase was intermediate 1 ethyl acetate solution.

[0061] (2) Add 500 g of purified water to the intermediate 1 solution obtained in step (1), add 24.9 g of hydrochloric acid, and separate the layers, remove the organic phase, raise the temperature of the water phase to 50 ° C for reaction, and hydrolyze for 0.5 h to obtain the intermediate 2;

[0062] (3) Add the aqueous solution of intermediate 2 obtained in step (2) to ethyl acetate, adjust the pH value to 12.0 with sodium hydroxide solution, separate the layers at rest, discard the water phase, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com