Electro-hydraulic spiral servo drive shearing fork type heavy lifting platform

A technology of servo drive and lifting platform, applied in the direction of lifting frame, lifting device, etc., can solve the problems of poor stability of workbench, poor structural rigidity, poor dynamic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

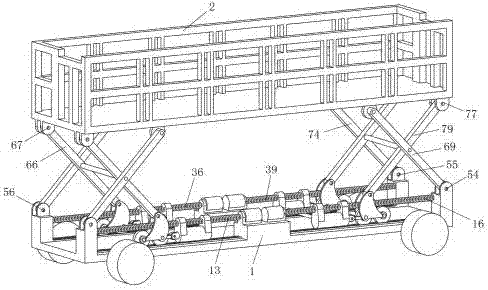

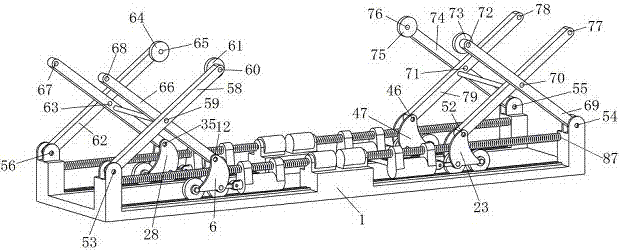

[0024] control figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 An electro-hydraulic helical servo-driven scissor-type heavy-duty lifting platform mainly includes a chassis 1, an electro-hydraulic helical servo drive system, a workbench 2, and a scissor-type structure.

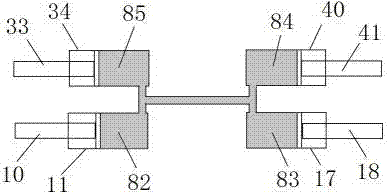

[0025] control figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , the scissor lift table is driven and controlled by an electro-hydraulic helical servo drive system, and the electro-hydraulic helical servo drive system consists of a first helical servo drive mechanism, a second helical servo drive mechanism, a third helical servo drive mechanism and a first helical servo drive mechanism. It consists of four helical servo drive mechanisms, and each of the helical servo drive mechanisms has the same component composition and component connection rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com