Concrete unloading device

A technology of unloading device and concrete, which is applied in the direction of clay preparation device, cement mixing device, chemical instrument and method, etc. It can solve the problems of no liquid leakage prevention function and only consideration, so as to realize automatic operation, prevent liquid leakage, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

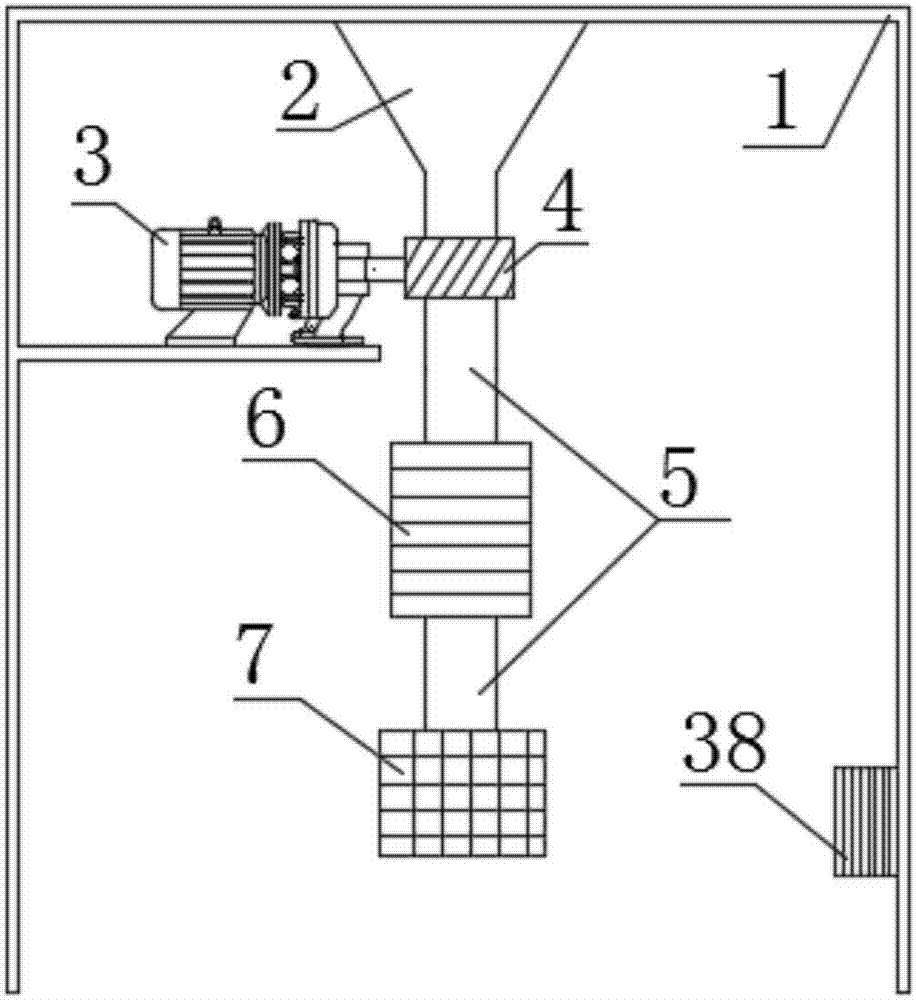

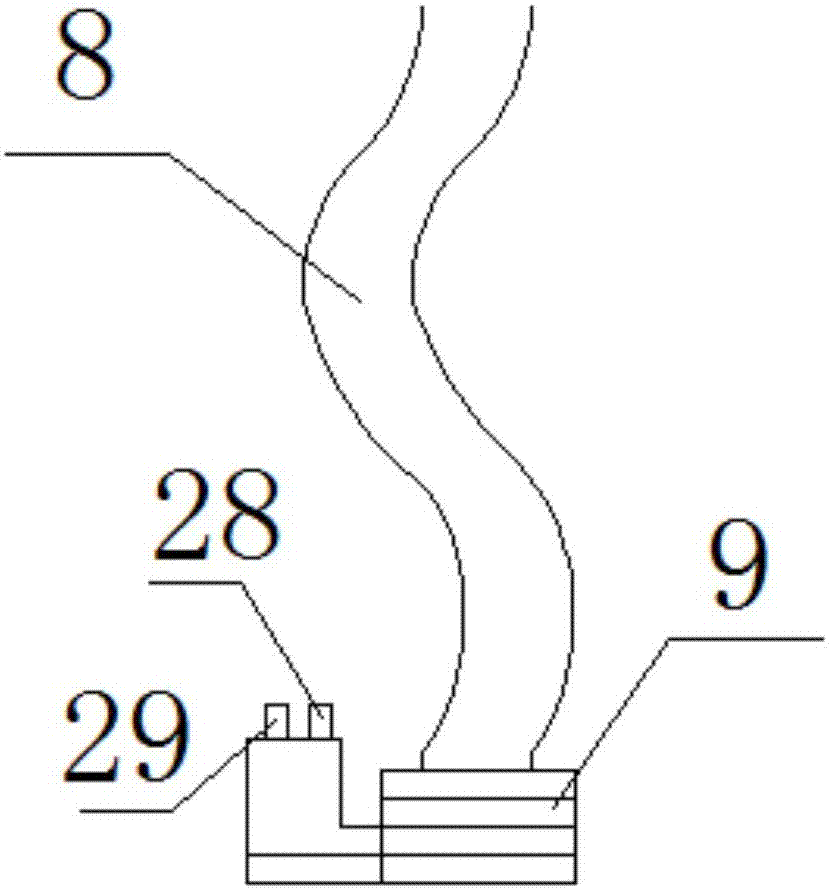

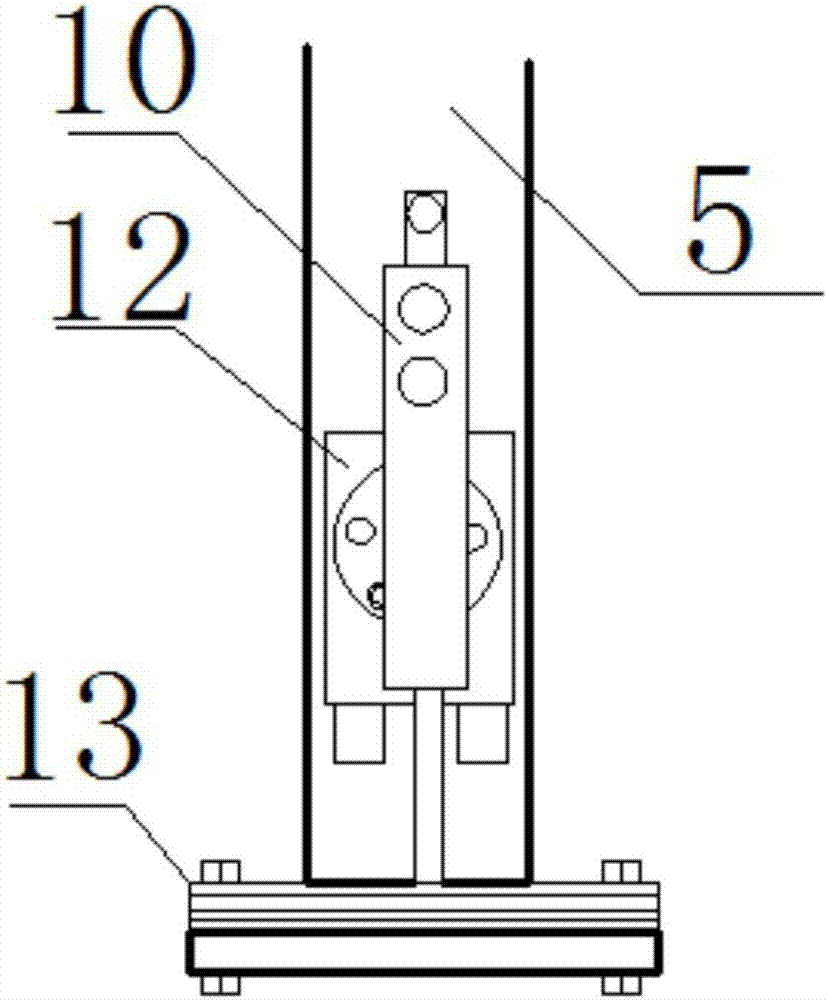

[0055] like Figure 1-7 As shown, a concrete unloading device includes a support frame 1, a hopper 2, a motor 3, a reducer 4, a pipeline 5, a control box 38, an anti-solid leakage module 6, an anti-liquid leakage module 7 and a control circuit;

[0056] The hopper 2 is fixed to the support frame 1, a reducer 4 is installed under the hopper 2, the motor 3 is fixed on the support frame 1, the rotating shaft of the motor 3 is connected with the reducer 4, and the solid leakage prevention module 6 It is connected to the reducer 4 through the pipeline 5 and installed at the lower part of the reducer 4. The liquid leakage prevention module 7 is connected with the solid leakage prevention module 6 through the pipeline 5 and installed at the lower part of the solid leakage prevention module 6. The control box 38 is fixed to the support frame 1, and a control circuit is installed inside the control box 38;

[0057] The anti-solid leakage module 6 is provided with an unloading pipeline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com