Optical path design control system and control method of laser etching machine

A technology of laser etching and design control, which is applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems affecting the conductive performance of the touch screen conductive film, and achieve the effect of complete functions, reasonable structure and good conductive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

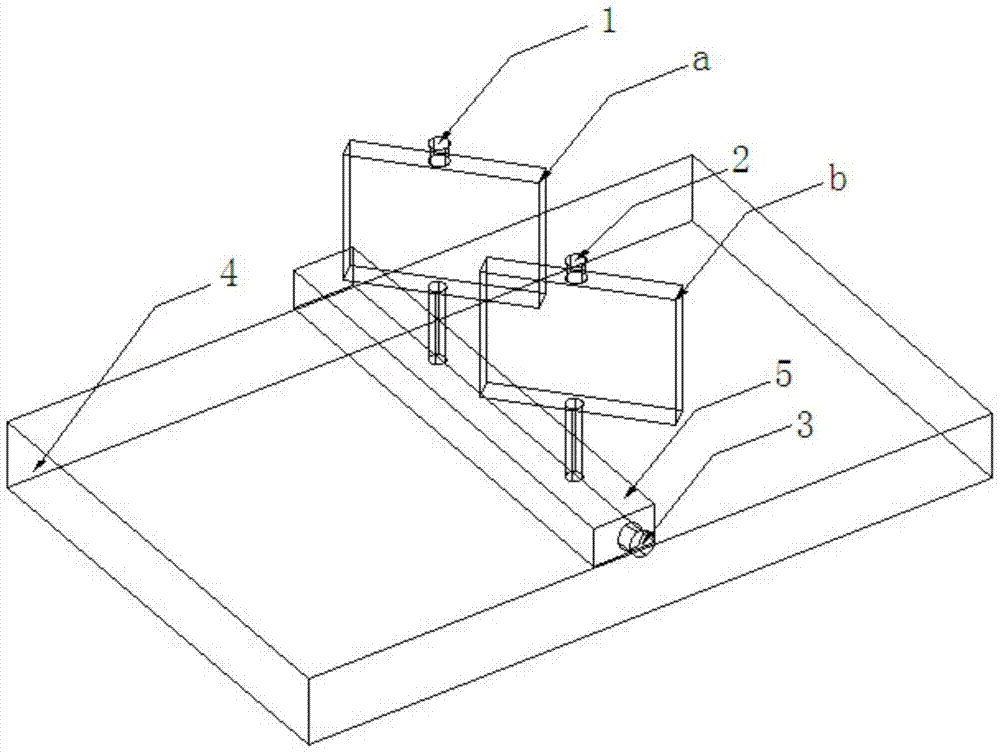

[0029] Further describe in detail below in conjunction with accompanying drawing and specific embodiment

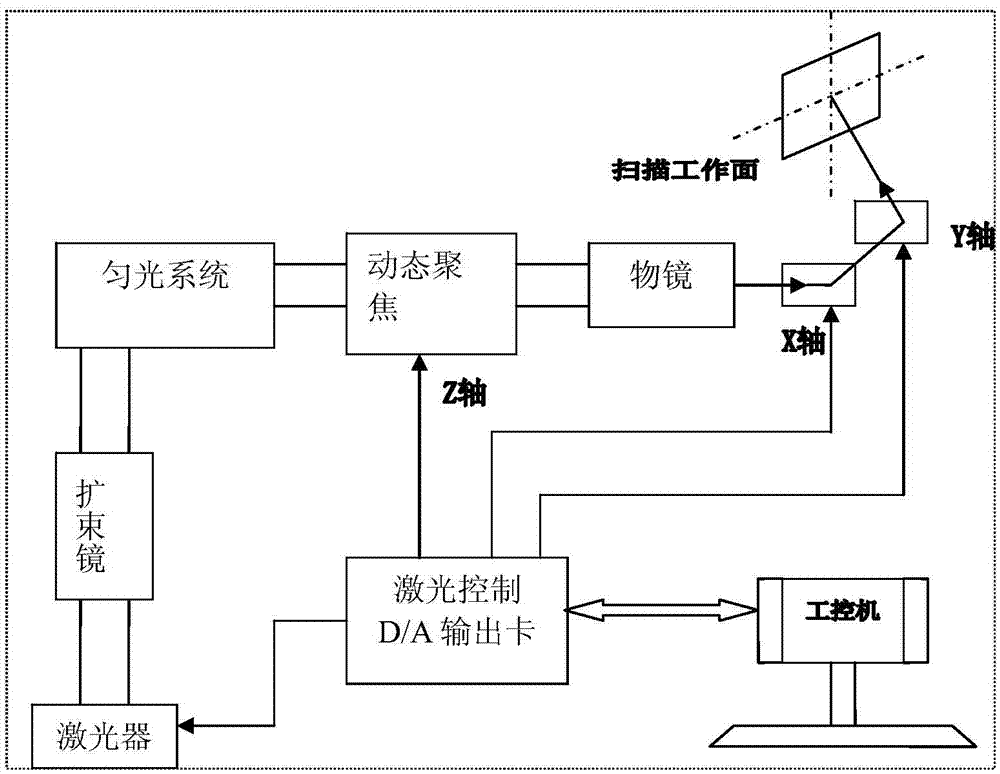

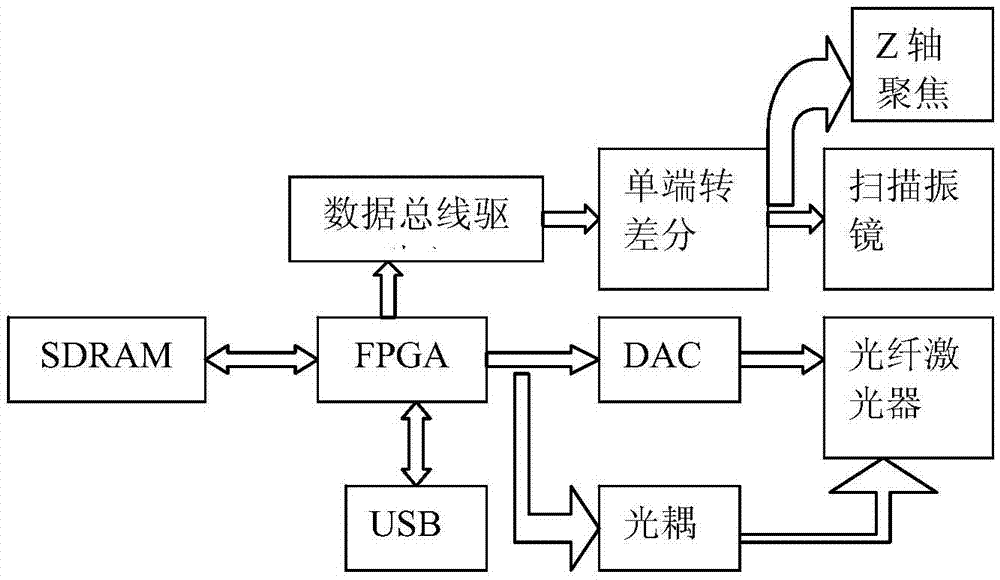

[0030] see figure 1 , an optical path design control system for a laser etching machine of the present invention is characterized in that it includes a laser, a beam expander, a uniform light system, a dynamic focusing system, an objective lens, a vibrating mirror scanning system, an industrial computer, and a laser control D / A output Card,

[0031] The laser beam output by the laser is first expanded by the beam expander and then transformed by the homogenization system to make the distribution of the laser beam more uniform, and the larger the beam diameter, the higher the collimation, which is conducive to focusing;

[0032] The beam expander adjusts the beam expansion factor by adjusting the distance between the two internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com