Probiotic gel particles and preparation method thereof

A technology of gel particles and probiotics, applied to bacteria, dairy products, and milk preparations used in food preparation, can solve the problems of inactivation of lactic acid bacteria and inability to obtain probiotics, restore the balance of flora, improve gastric Good intestinal function and heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

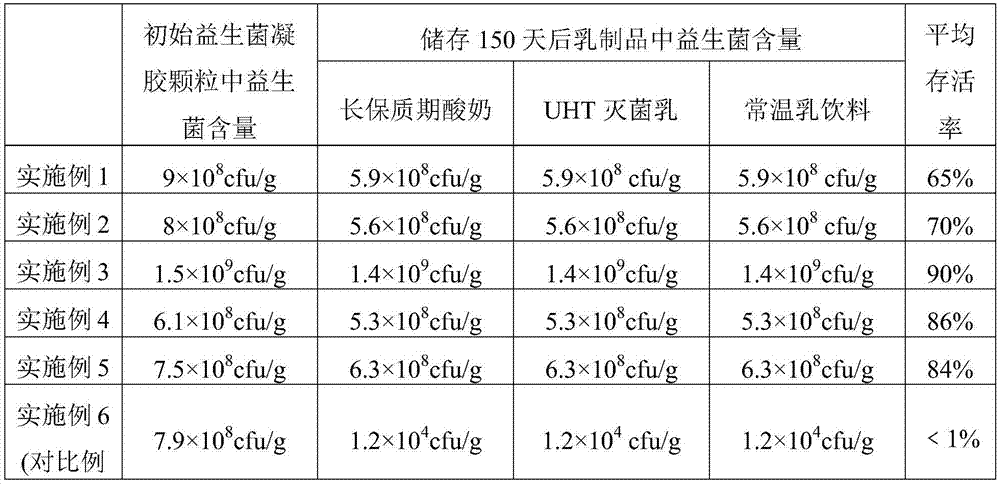

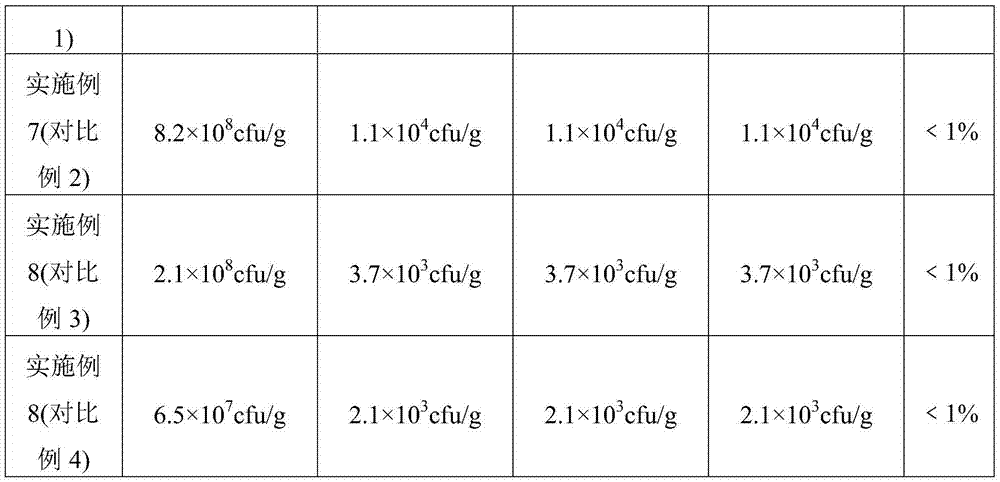

Examples

Embodiment 1

[0027] raw material:

[0028] Carrageenan: 5 kg;

[0029] Konjac Gum: 20kg;

[0030] Edible oils and fats: selected from sunflower oil, the dosage is 20 kg;

[0031] Liquid culture medium: selected from MRS medium, the dosage is 25 kg;

[0032] Probiotic bacteria powder: selected from bifidobacteria, the dosage is 2 kg;

[0033] Probiotic bacteria powder: selected from Streptococcus thermophilus, the dosage is 5 kg;

[0034] Water: make up to 1000 kg (the amount of water here does not include the sterile water used for condensation in the following step 6).

[0035] Preparation:

[0036] 1. Heat 400 kg of water to 85°C, add the pre-mixed carrageenan and konjac gum, mix and stir for 15 minutes, the carrageenan and konjac gum are completely dissolved, then add the remaining water, and use a scraper-type sterilizer at 120 after mixing. Sterilize at °C for 5 minutes to obtain a sol solution (during the preparation process, the temperature of the sol solution must not be lowe...

Embodiment 2

[0042] raw material:

[0043] Carrageenan: 10 kg;

[0044] Konjac Gum: 10kg;

[0045] Edible oil: selected from sunflower oil, the dosage is 40 kg;

[0046] Liquid culture medium: selected from MRS medium, the dosage is 10 kg;

[0047] Probiotic bacteria powder: selected from Lactobacillus paracasei, the dosage is 3 kg;

[0048] Water: make up to 1000 kg.

[0049] Preparation:

[0050] 1. Heat 400 kg of water to 95°C, add the pre-mixed carrageenan and konjac gum, mix and stir for 10 minutes, the carrageenan and konjac gum are completely dissolved, then add the remaining water, and use a scraper-type sterilizer at 125 after mixing. Sterilize at °C for 3 minutes to obtain a sol solution (during the preparation process, the temperature of the sol solution must not be lower than 38 °C);

[0051] 2. Mix the probiotic bacteria powder with the liquid culture medium at 42°C for 3 minutes to make it evenly mixed to obtain the probiotic bacteria base material;

[0052] 3. Mix and...

Embodiment 3

[0056] raw material:

[0057] Carrageenan: 15 kg;

[0058] Konjac Gum: 5kg;

[0059] Edible oil: selected from sunflower oil, the dosage is 21 kg;

[0060] Liquid culture medium: selected from TPY medium, the dosage is 5 kg;

[0061] Probiotic bacteria powder: selected from bifidobacteria, the dosage is 2 kg;

[0062] Water: make up to 1000 kg.

[0063] Preparation:

[0064] 1. Heat 400 kg of water to 90°C, add the pre-mixed carrageenan and konjac gum, mix and stir for 5 minutes, the carrageenan and konjac gum are completely dissolved, then add the remaining water, and use a scraper-type sterilizer at 130 after mixing. Sterilize at °C for 1 minute to obtain a sol solution (during the preparation process, the temperature of the sol solution must not be lower than 38 °C);

[0065] 2. Mix the probiotic bacteria powder with the liquid culture medium at 40°C for 2 minutes to make it evenly mixed to obtain the probiotic bacteria base material;

[0066] 3. Mix and stir the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com