A plunge-cut banana comb cutter

A technology for knives and bananas, applied in the field of plunge-cut banana combing knives, can solve the problems of low level of mechanization application, unfavorable banana fresh sales, high labor intensity, etc., to improve overall aesthetics, ensure the effect of combing, and reduce physical strength. effects of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

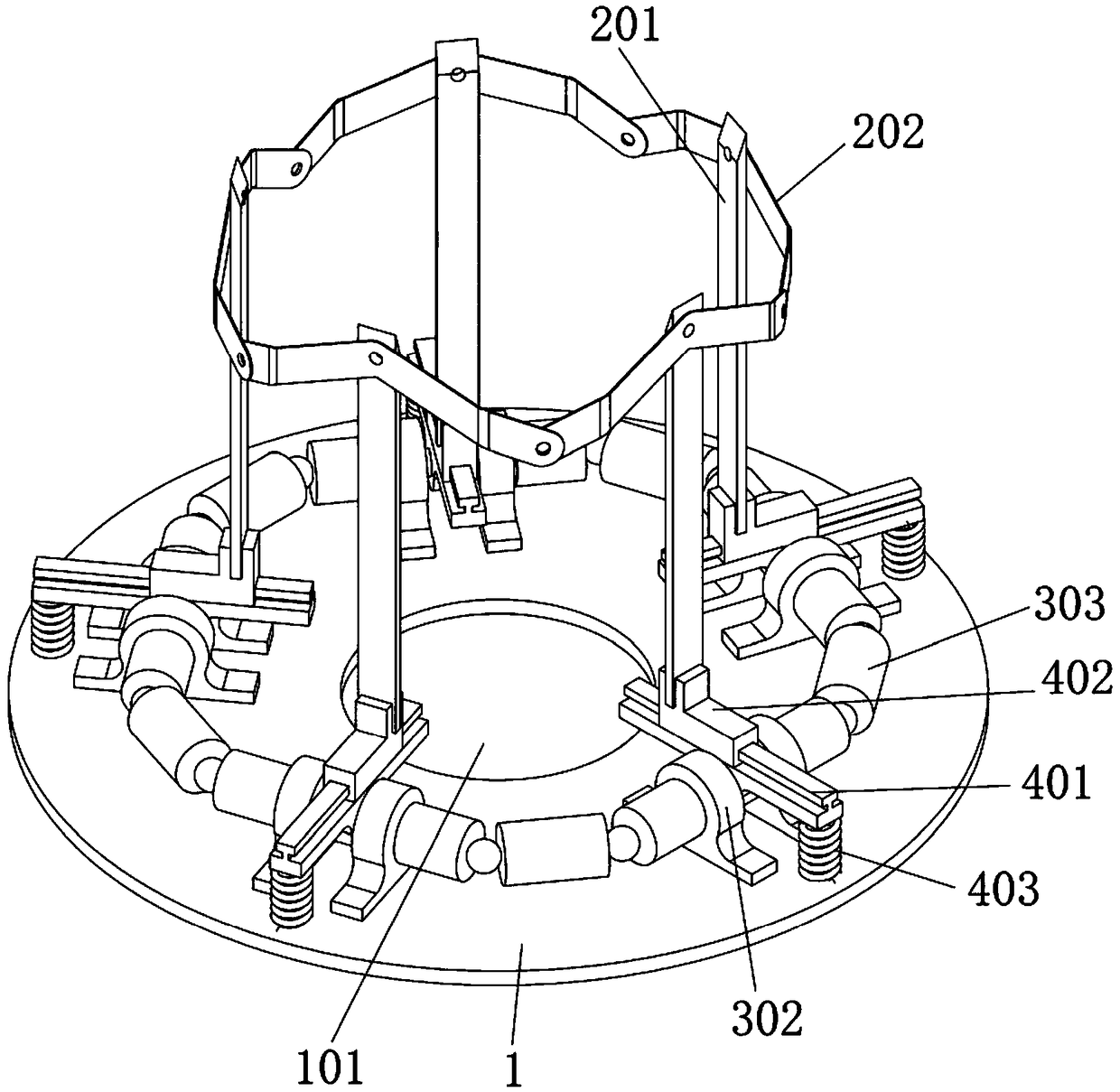

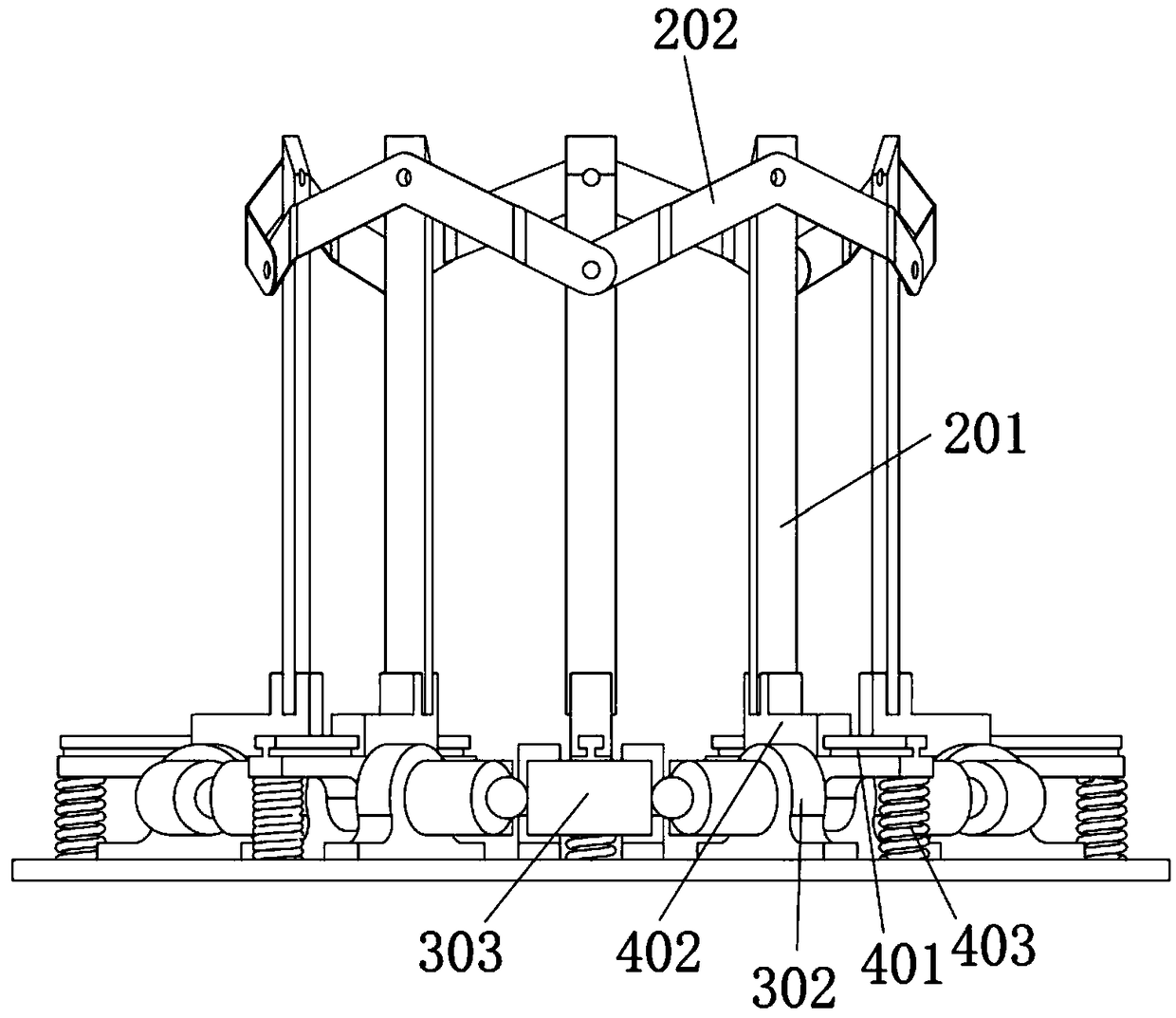

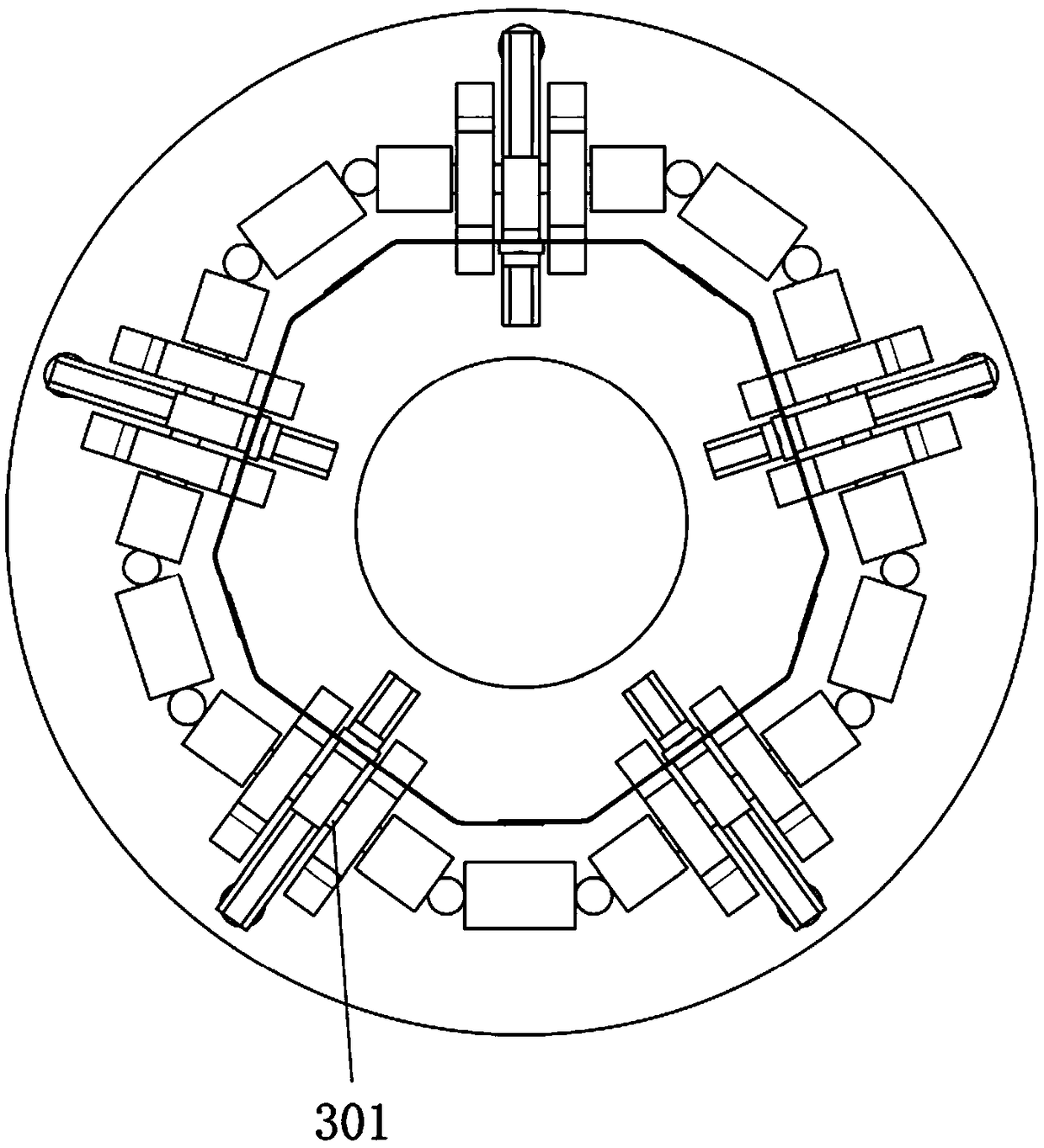

[0020] see Figure 1 to Figure 3 As shown, the insert-cut banana combing tool described in this embodiment is mainly aimed at the deshafting and combing operation of the whole string of bananas, so as to achieve the purpose of mechanized deshafting and combing of the whole string of bananas. The plunge-cut banana combing tool includes a circular cutterhead 1, an encircling structure cutter group, a cutter synchronization unit, and a cutter spacing adjustment unit; Through the through hole 101, the tool synchronization unit has a plurality of uniformly distributed on the cutter head 1 around the through hole 101, and the double ten word 303 (which can be changed to a universal joint or a flexible shaft) is passed between two tool synchronization units. ) connection, each tool synchronization unit is equipped with a tool spacing adjustment unit; the encircling structure tool se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com