Mechanical switch device

A technology of mechanical switches and support seats, applied in the direction of contact operating parts, etc., can solve the problems of expensive high-precision sensors, unreliable action of thermal detection, and inadaptability to harsh working conditions, etc., to eliminate hidden dangers to personnel safety and simple structure , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

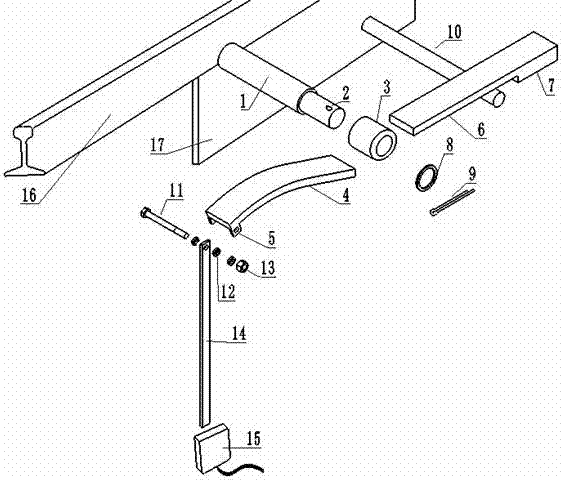

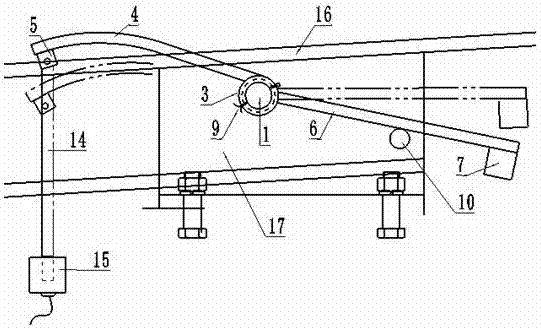

[0019] Example 1, see figure 1 , 2 According to the design needs, select the appropriate inclined grate bar support seat 17 and inclined grate bar 16, and the inclined grate bar 16 is installed on the inclined grate bar support seat 17; Grate bar support seat 17 forms 90°; Then two pin lugs 5 are welded on both sides below the head of the arc-shaped working arm 4, and then the arc-shaped working arm 4 is welded on one side of the shaft sleeve 3, and the counterweight arm 6 is welded on the other side of the shaft sleeve 3, the angle between the arc-shaped working arm 4 and the counterweight arm 6 can be determined according to the actual needs of the site, and the best is 180 °; then the arc-shaped working arm 4, The pin lug 5 and the shaft sleeve 3 of the counterweight arm 6 are installed on the shaft 1. The inner diameter of the shaft sleeve 3 must be larger than the outer diameter of the shaft 1 by about 1mm during processing, so as to ensure that the shaft sleeve 3 can ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com