Electrochromic device and application thereof in field of rearview mirror preparation

An electrochromic device and device packaging technology, which is applied in instruments, vehicle parts, optics, etc., can solve the problems of accelerated discoloration response speed, and achieve the effects of fast fading speed, uniform discoloration and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1 This implementation discloses an electrochromic device, the electrochromic device includes an electrolyte layer, the electrolyte layer includes a gel electrolyte and a frame glue, and the gel electrolyte electrolyte includes 8 parts by weight A silicone-modified UV-curable adhesive and 92 parts by weight of electrolyte; the frame glue is a silicone-modified UV-curable adhesive with good weather resistance and resistance to organic solvent corrosion.

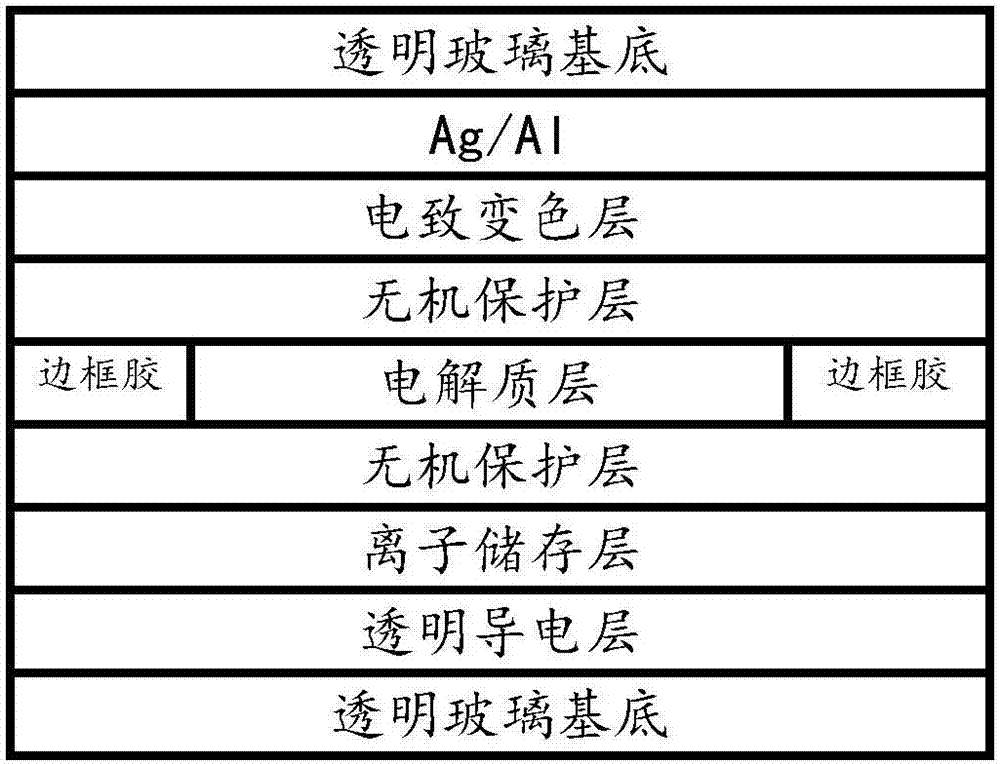

[0022] First, the electrolyte and the silicone-modified UV-curable adhesive are mixed uniformly at a ratio of 92:8 for use; Al, WO3, and nitrogen-doped lithium phosphate (LiPON) are sequentially plated on a transparent substrate by magnetron sputtering. Protective layer, another transparent substrate is coated with ITO, lithium-titanium co-doped nickel oxide, nitrogen-doped lithium phosphate (LiPON) protective layer in sequence, and then a silicone-modified UV-curable adhesive is used as a frame glue to connect th...

Embodiment 2

[0025] Example 2 This implementation discloses an electrochromic device, the electrochromic device includes an electrolyte layer, the electrolyte layer includes a gel electrolyte and a frame glue, and the gel electrolyte contains 20 parts by weight of Silicone-modified UV-curable adhesive and 80 parts by weight of electrolyte; the frame glue is a silicone-modified UV-curable adhesive with good weather resistance and resistance to organic solvent corrosion.

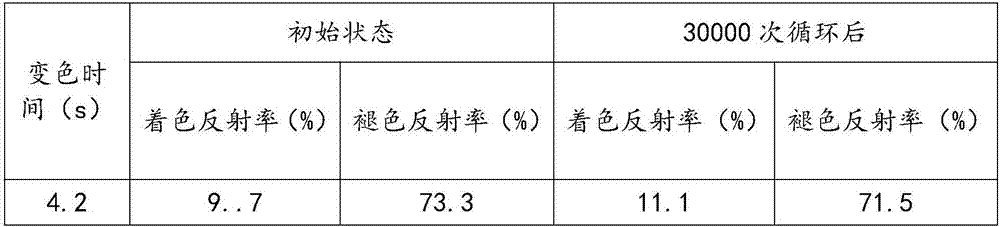

[0026] First, the electrolyte and the silicone-modified UV-curable adhesive are mixed uniformly according to the ratio of 80:20; then Ag, WO3, doped Lithium nitrogen phosphate (LiPON) protective layer; another transparent substrate is coated with ITO, lithium iron phosphate, and nitrogen-doped lithium phosphate (LiPON) protective layer in sequence, and then a hot melt adhesive modified with ethylene-octene copolymer Make a frame glue to bond the LiPON surfaces of the two electrodes, leaving a 100μm cavity in the middle; fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com