Silicon chip correcting equipment

A technology of equipment and silicon wafers, applied in electrical components, conveyor objects, transportation and packaging, etc., can solve the problems of scrapping silicon wafers, increasing production costs, and chipping of silicon wafers, and achieves the effect of high correction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

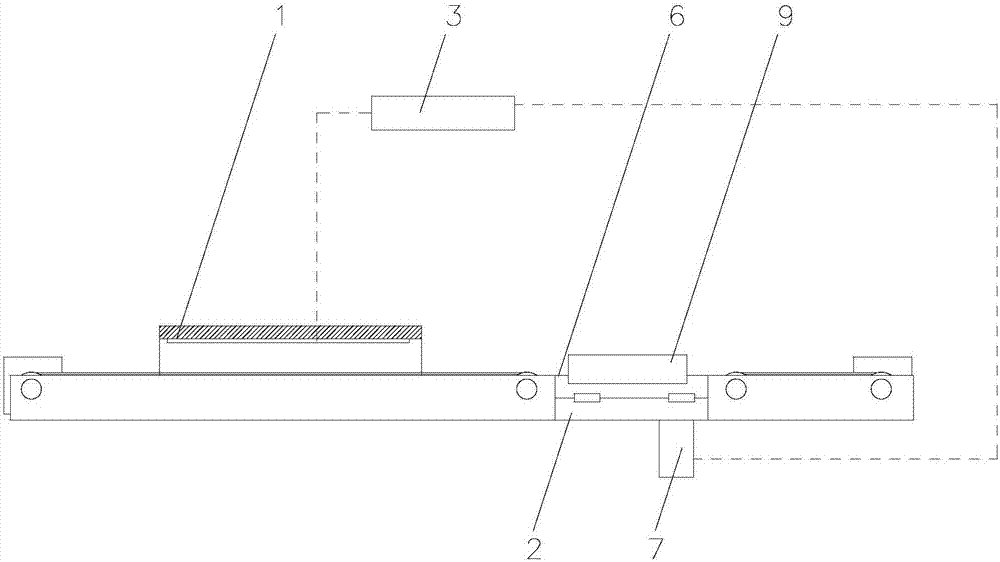

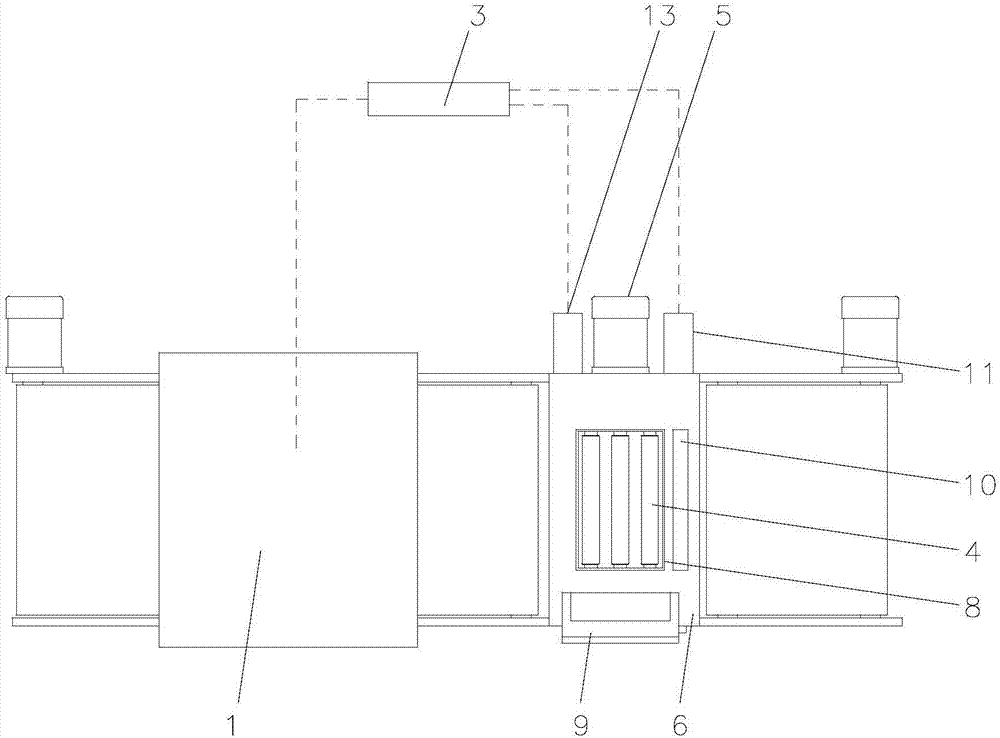

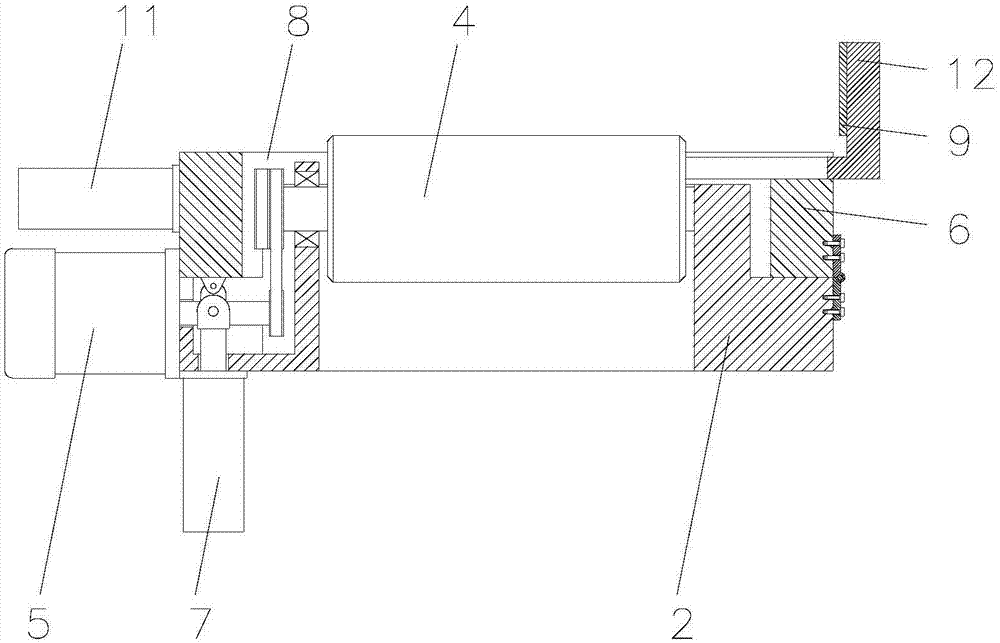

[0016] Such as Figure 1-3 As shown, a silicon wafer straightening device includes a detection device 1, a frame 2 and a control unit 3, the frame 2 is provided with a roller shaft 4 for rotation, and the frame 2 is provided with a roller shaft for driving the roller shaft 4 to rotate The motor 5, the frame 2 is provided with a substrate 6 for rotation, the frame 2 is provided with a first driving device 7 for driving the substrate 6 to rotate, the substrate 6 is provided with a groove 8, and the roller The shaft 4 is located in the groove 8, the base plate 6 is slidably provided with a limit plate 9 at one end of the axis direction of the roller shaft 4, and the frame 2 is provided with a second driving device 13 for driving the limit plate 9 to slide. , the base plate 6 is provided with a partition 10, the partition 10 is located at the output end of the roller shaft 4, and the base is provided with a third driving device 11 for driving the partition 10 to rise or fall, so ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap